To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

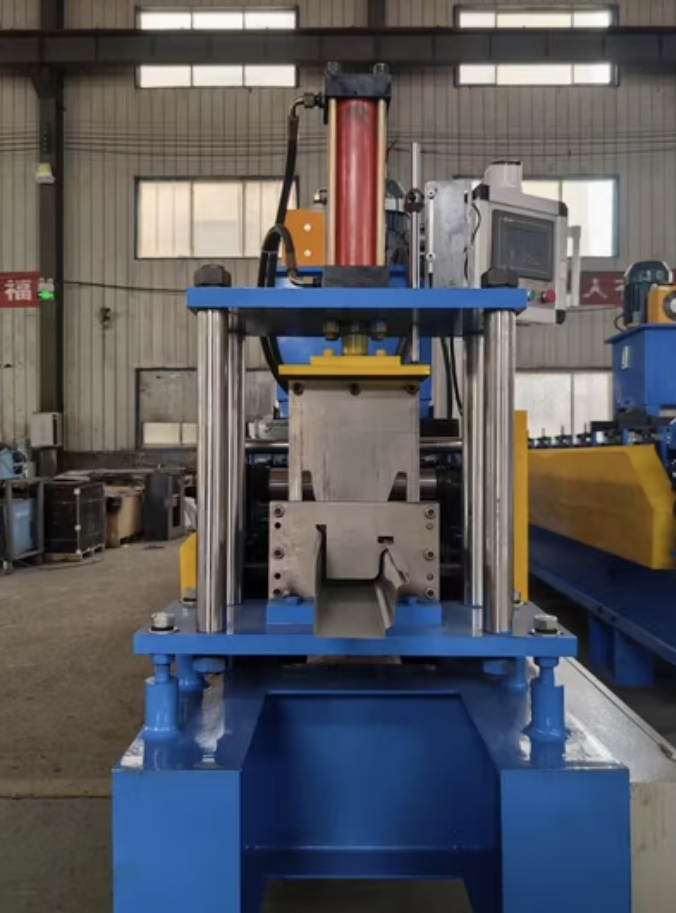

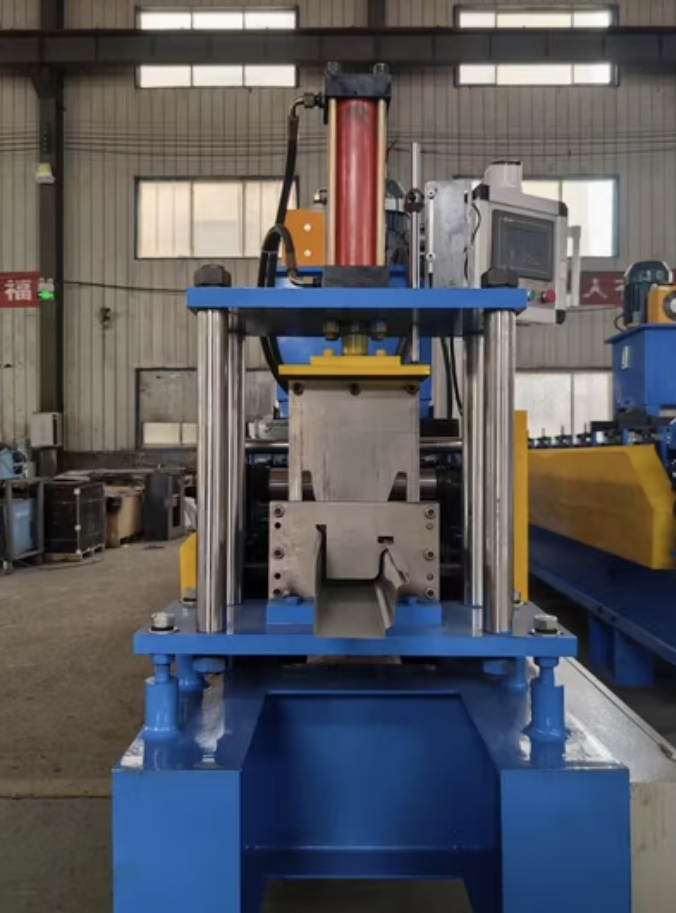

A gutter roll forming machine is a specialized piece of equipment designed to produce high-quality gutters used in residential, commercial, and industrial buildings. These machines are essential for fabricating gutters of different shapes, sizes, and materials efficiently and accurately. They cater to the growing demand for durable and aesthetically pleasing gutter systems across various industries.

A gutter roll forming machine transforms metal coils into custom gutter profiles through a continuous bending process. This machine is engineered for efficiency, precision, and durability, enabling manufacturers to produce consistent, high-quality gutter profiles.

Key Features:

Q1: What materials can be used with a gutter roll forming machine?

A1: Most machines can process aluminum, galvanized steel, stainless steel, and copper. Material thickness typically ranges from 0.3 mm to 1.0 mm.

Q2: Can one machine produce multiple gutter profiles?

A2: Yes, with interchangeable rollers or additional components, the machine can produce different profiles like K-style or half-round gutters.

Q3: How long does it take to set up the machine for production?

A3: Setup time varies depending on the complexity of the profile, but most modern machines are designed for quick setup, typically under 30 minutes.

Q4: What is the average production speed of a gutter roll forming machine?

A4: The production speed ranges from 10 m/min to 25 m/min, depending on the material type and profile design.

Q5: Is it possible to customize the machine to specific requirements?

A5: Yes, manufacturers can customize the machine to meet specific size, profile, and material requirements.

Q6: What are the main considerations when purchasing a gutter roll forming machine?

A6: Factors include the machine's production speed, material compatibility, profile versatility, motor power, and ease of operation.

Q7: How often should the machine undergo maintenance?

A7: Maintenance schedules depend on usage frequency, but a general guideline is monthly checks and lubrication, with an annual comprehensive inspection.

Copyright 2026 © Machine Matcher.