To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Gutter Roll Forming Machine – UAE Edition

Precision Engineered. Custom Delivered. Built for the UAE Market.

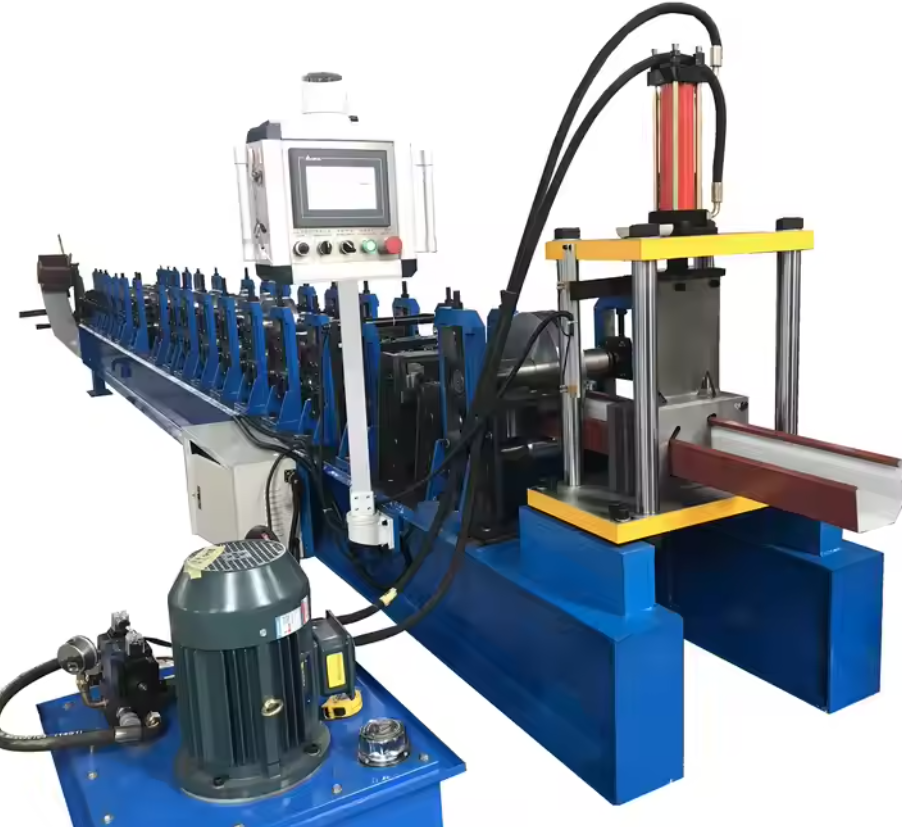

The Gutter Roll Forming Machine is a high-precision, high-efficiency machine designed to produce rain gutters in a variety of profiles, ideal for the UAE's dynamic construction and architectural sectors. Built with durability, flexibility, and automation in mind, this machine caters to both residential and commercial drainage system projects across cities like Abu Dhabi, Dubai, Sharjah, and other Emirates.

Whether for traditional K-style gutters, half-round gutters, or custom architectural profiles, the machine guarantees consistent performance with minimal waste, making it a top-tier solution for metal forming professionals in the region.

Construction & Infrastructure – For residential, commercial, and industrial building projects

Roofing & Drainage Contractors – To produce gutters on demand

Architectural Sheet Metal Fabricators – For custom or designer gutter profiles

Prefab Building Manufacturers – For integrated rainwater management systems

Examples of Use:

On-site gutter manufacturing for villa and high-rise developments

Factory production of standard gutter profiles in aluminum or galvanized steel

Supplying retail and wholesale markets with ready-made gutter systems

Machine Type: Gutter Roll Forming Machine

Production Speed: 10–20 meters/min (adjustable depending on profile and material)

Material Thickness Range: 0.4 – 0.8 mm

Material Width Range: 200 – 500 mm

Material Types: Galvanized steel, color-coated steel, aluminum, copper

Material Yield Strength: Up to 250 MPa (36 ksi)

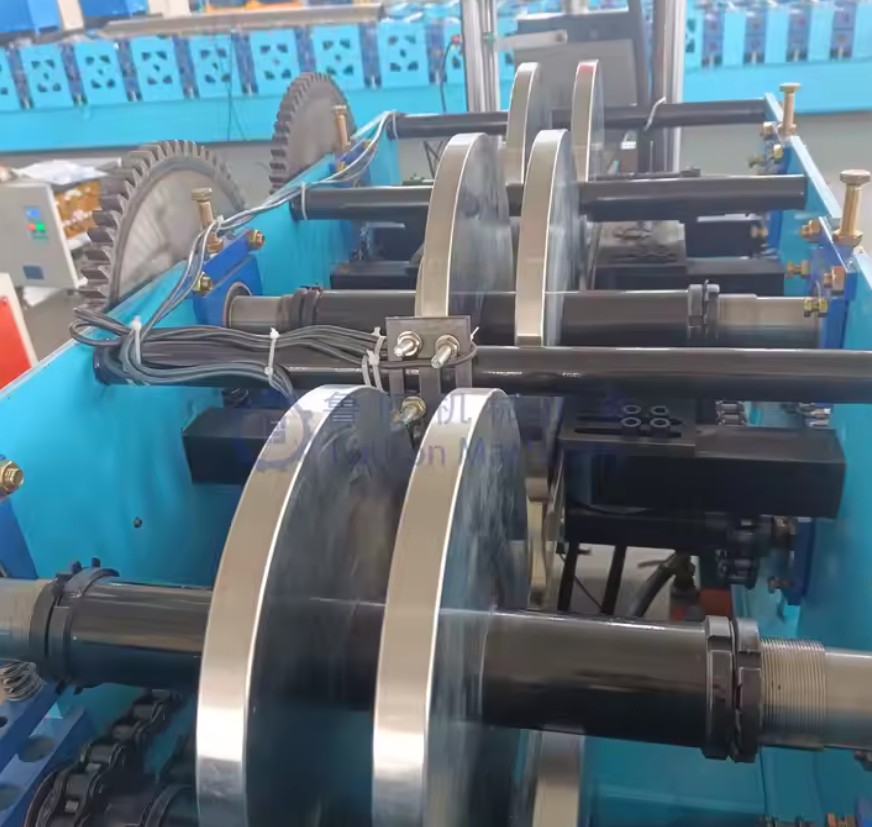

Roller Material: High-grade 45# steel with hard chrome plating

Roller Surface Treatment: Hard chrome-coated for anti-wear and corrosion resistance

Number of Forming Stations: 12–20 stations (based on profile complexity)

Roller Shaft Diameter: 60 mm

Shaft Material: High-strength steel, heat-treated

Main Drive Type: Chain drive / gearbox drive (as specified)

Power for UAE: 380V / 50Hz / 3-phase (customizable)

Motor Power: 5.5–7.5 kW (depending on profile and speed)

Cutting Method: Hydraulic post-cutting system

Blade Material: Cr12Mov steel, heat-treated

Control Type: PLC control with touchscreen HMI (Siemens/Delta)

Operating Mode: Automatic or Manual

De-coiling System: Manual or hydraulic uncoiler (3–5 tons capacity)

Punching/Notching System: Optional (for outlets or brackets)

Machine Frame: Welded steel structure, stress-relieved

Thickness of Frame Steel: 20–30 mm

Profile Shape: K-style, half-round, box gutter, or custom

Profile Width and Depth: Customizable according to client specs

Length Tolerance: ±1.5 mm

Safety Features:

Fully enclosed protective covers/guards

Emergency stop button

Overload protection for electrical and hydraulic systems

Galvanized Steel: 0.5–0.7 mm, 33–36 ksi

Aluminum: 0.6–0.8 mm, 20–30 ksi

Color-coated steel: 0.4–0.6 mm, up to 36 ksi

Copper (optional): 0.5–0.6 mm

Average Base Price (Standard Gutter Machine):

Starting at USD $36,000

Final pricing depends on customization, profile complexity, motor and control system brand, and optional extras such as punching units, hydraulic uncoilers, and stackers.

Profile Flexibility – Supports multiple gutter styles for the UAE market

High Automation – Reduces labor costs and operator training time

Local Power Setup – Built for 380V/50Hz grids used in the UAE

Durable Rollers – Designed for high-volume production and low maintenance

Custom Design Options – Send your profile drawing and we’ll build the machine around it

Energy Efficient Systems – Optimized motor use to reduce power consumption

How it Benefits You:

Lower production waste → Cost savings

Precision forming → Professional finish

Fast changeovers → Higher productivity

Tailored configuration → Meets specific market needs

Custom profile sizes and depths

Material-specific setups (steel, aluminum, copper)

Hydraulic uncoiler (3-ton or 5-ton)

Servo-feeding systems

Automated stacking units

Remote monitoring/PLC programming interface

All machines are new and custom-built.

Delivery is available throughout the UAE, including:

Abu Dhabi, Dubai, Sharjah, Ajman, Ras Al Khaimah, Fujairah, and Umm Al Quwain

Machines are supplied in partnership with trusted manufacturers and come with one-year warranty and ongoing maintenance support.

If you have a gutter profile drawing, material type, width, or desired output capacity, send it directly to:

[email protected]

We’ll provide a detailed technical recommendation and quote based on your exact needs.

Q1: Can this machine make different gutter profiles?

Yes, it can be configured for different shapes like K-style, half-round, or box gutters. Each setup is tailored to your requirements.

Q2: Can I run both aluminum and steel on the same machine?

Yes. With the right roller design and machine setup, you can switch between aluminum and steel materials.

Q3: How long does it take to manufacture and ship the machine to the UAE?

Manufacturing time is typically 45–60 days. Shipping and installation depend on your location, but we deliver anywhere in the UAE.

Q4: Do I need a trained operator?

Our machines come with PLC controls and intuitive HMI panels, making them easy to operate. Basic training is also provided.

Q5: What kind of support do you offer after delivery?

We offer a 12-month warranty and ongoing support for troubleshooting, spare parts, and technical assistance.

The Gutter Roll Forming Machine – UAE Edition is a reliable, efficient, and customizable machine for any contractor or manufacturer in the region. Built to withstand the UAE’s demanding climate and production standards, it delivers both performance and value.

Machine Matcher ensures you get a tailor-fit machine for your gutter production needs—with full support, expert advice, and delivery right to your workshop.

For technical drawings, specifications, or order inquiries, contact us at [email protected].

Copyright 2026 © Machine Matcher.