To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

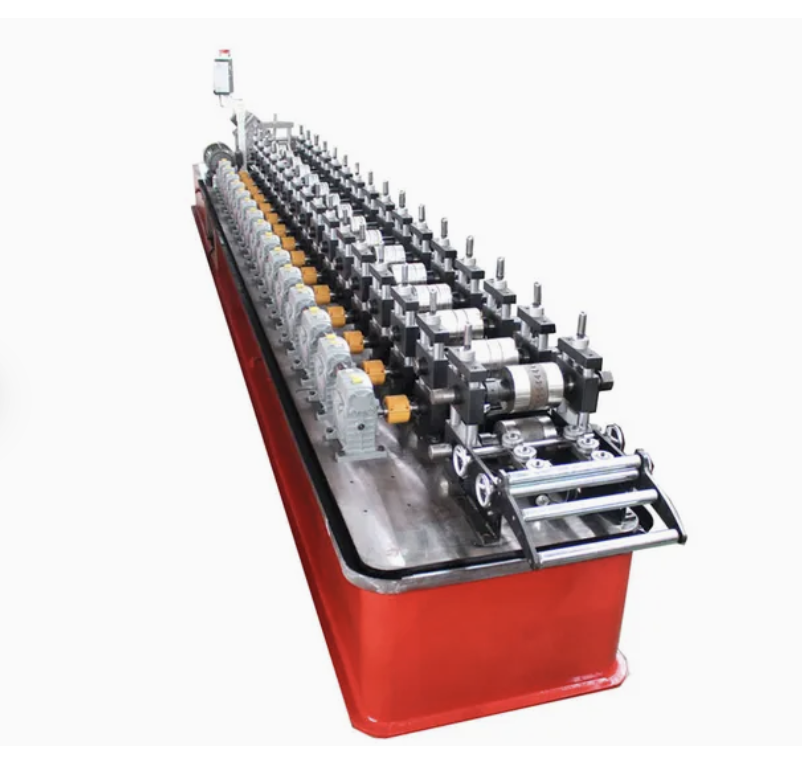

A gypsum channel roll forming machine is designed to create metal channels used in drywall systems, particularly for gypsum board installations. These channels, often known as furring channels or gypsum channels, are used in construction to support plasterboard walls and ceilings. Here's an outline of typical specifications and a general description of a gypsum channel roll forming machine:

A gypsum channel roll forming machine automates the process of shaping metal coils into gypsum channels used in drywall framing systems. The machine feeds galvanized or aluminum coil stock through a series of rollers that progressively bend the metal into the desired profile. Equipped with a PLC control system, the machine allows users to set precise dimensions, quantities, and cut lengths, facilitating high production rates with minimal manual intervention.

This machine is highly efficient, producing uniform channels with excellent structural integrity, and is suitable for a range of construction projects that use gypsum boards for wall and ceiling systems.

Copyright 2026 © Machine Matcher.