To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

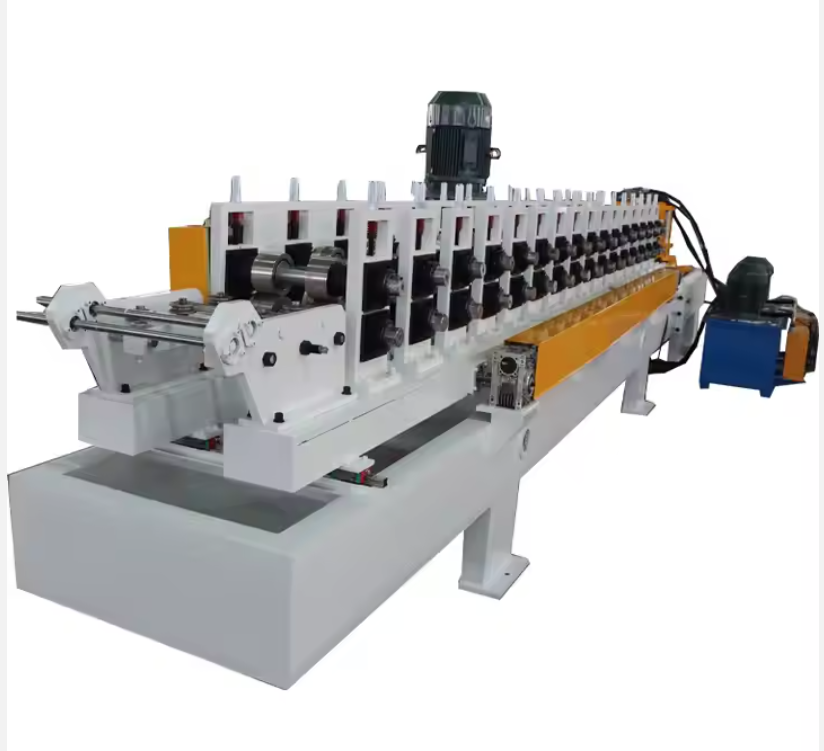

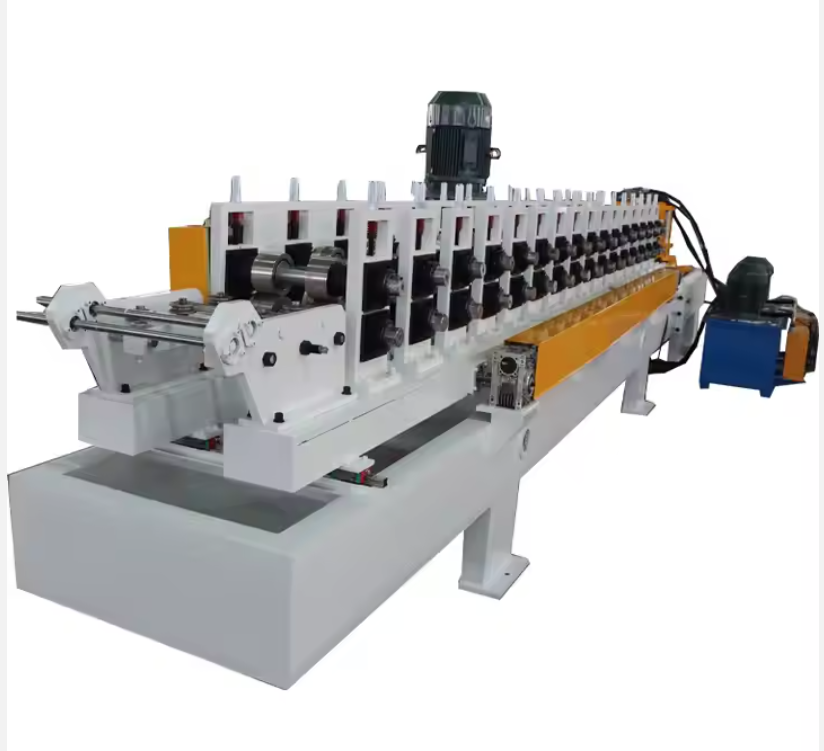

H-Channel Roll Forming Machine – UAE Market Edition

High-Precision, High-Efficiency Forming for Structural and Architectural Applications

The H-Channel Roll Forming Machine is a robust and high-precision production system designed to manufacture H-shaped metal profiles with exceptional accuracy and consistency. This machine is ideal for structural framing, curtain walls, cable support systems, solar mounting, industrial racking, and architectural metalwork. Built for operation in the UAE, it is fully optimized for regional voltage and environmental conditions.

Every unit is custom-built to the buyer’s required profile dimensions, material type, and thickness, ensuring seamless integration into local manufacturing lines in Abu Dhabi, Dubai, Sharjah, and across the United Arab Emirates.

Machine Type: H-Channel Cold Roll Forming Machine

Application Areas: H-profile channels for framing systems, electrical trunking, window and door frames, racking, and mechanical structures

Capabilities: Precision roll forming of H-channel profiles from various metal materials; optional integration with punching and notching units for complex designs

Examples of Use:

Construction: Framing and support structures

Electrical: Enclosures and trunking

Industrial Manufacturing: Structural reinforcement

Solar & Infrastructure: Mounting systems and cable management

Construction & Infrastructure

Electrical & Cable Management

Solar Energy & Mounting Systems

HVAC & MEP Contractors

Industrial Equipment Manufacturers

Racking, Shelving & Storage Solutions

These industries benefit from the machine’s high speed, profile consistency, and long-term durability—critical for bulk production and industrial-grade applications.

Machine Type: Automatic Cold Roll Forming Line – H-Channel

Production Speed: 15–30 meters per minute

Material Thickness Range: 0.6 mm – 2.0 mm

Material Width Range: 60 mm – 300 mm

Material Types: Galvanized steel, mild steel, stainless steel, aluminum

Material Yield Strength: Up to 550 MPa (80 KSI)

Roller Material: GCr15 hardened steel

Roller Surface Treatment: Chrome-plated for extended life and corrosion resistance

Number of Forming Stations: 12–18 stations (varies by profile)

Roller Shaft Diameter: 60 mm

Shaft Material: 45# steel, precision ground and quenched

Main Drive Type: Chain or gearbox drive (customizable)

Power (UAE specification): 380V / 50Hz / 3-phase

Motor Power: 7.5 kW – 15 kW (depending on configuration)

Cutting Method: Hydraulic post-cutting system

Blade Material: Cr12Mov heat-treated steel

Control Type: PLC automatic control with HMI touch screen (Siemens or Delta)

Operating Mode: Fully automatic with manual override options

De-coiling System: Manual or hydraulic uncoiler (3T to 5T optional)

Punching/Notching System: Optional hydraulic punching unit with programmable dies

Machine Frame: Welded steel frame with stress relief treatment

Thickness of Frame Steel: 18–22 mm

Profile Shape: H-channel with customizable leg depth and flange widths

Profile Width and Depth: Widths: 30–150 mm | Depths: 20–100 mm

Length Tolerance: ±1.0 mm

Safety Features:

Protective guarding

Emergency stop buttons

Overload protection system

Typical Material Used: Galvanized Steel, Mild Steel, Stainless Steel, Aluminum

Gauge Range: 0.6 mm to 2.0 mm

Yield Strength: 240–550 MPa (35–80 KSI)

Starting Price: From USD $45,000 depending on features, automation level, and profile complexity

What Affects the Final Price:

Profile design and size

Material gauge and type

Integration of punching or embossing systems

Speed requirements

Choice of PLC system (Siemens, Delta, etc.)

Hydraulic vs. manual uncoilers or stackers

Packaging and delivery options

Contact us for an accurate quote based on your custom specifications.

Custom H-profile drawings and tooling

Material-specific roller sets

Servo-driven feeding and punching

Automatic stackers and conveyors

Remote monitoring and diagnostics

Multi-language PLC/HMI interfaces

Integration with existing factory automation systems

All machines are brand new and custom-built, designed according to customer-specific profiles and operational requirements. This H-Channel Roll Forming Machine can be delivered anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and other cities. Installation, commissioning, and training can be arranged locally or remotely.

Tight tolerance control, ideal for projects demanding high-quality profile matching.

Adaptable for new profiles or project changes—future-proof your investment.

Voltage, temperature, and material specs are suited for UAE's industrial conditions.

Reduces labor cost per meter by increasing production efficiency.

1-year warranty plus long-term maintenance and parts support available.

Optional full automation with integration into existing ERP/MES systems.

Q: Can this machine produce different H-channel sizes?

A: Yes. The machine can be configured with adjustable tooling or multiple profile sets depending on your requirements.

Q: What materials are best for use in the UAE environment?

A: Galvanized steel and aluminum are most common due to corrosion resistance in coastal and desert climates.

Q: How long does it take to manufacture and deliver the machine to the UAE?

A: Lead time is typically 45–60 days. Delivery to the UAE is coordinated directly through our international logistics partners.

Q: Can I request integration of a punching system?

A: Absolutely. We offer optional punching, embossing, and slotting systems tailored to your profile.

Q: What support is available after purchase?

A: We provide one-year warranty and ongoing support for troubleshooting, maintenance, and spare parts.

Q: Where should I send my profile drawings or specs for quoting?

A: Please email your profile drawings and machine requirements to: [email protected]

The H-Channel Roll Forming Machine for the UAE is a dependable, high-efficiency solution for businesses involved in structural framing, electrical channel production, or industrial assembly. Built to perform under tough conditions and meet evolving project demands, this machine offers excellent ROI for manufacturers looking to scale or modernize their profile production.

Contact Machine Matcher today to get a personalized quote and technical consultation tailored to your production goals.

Copyright 2026 © Machine Matcher.