To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

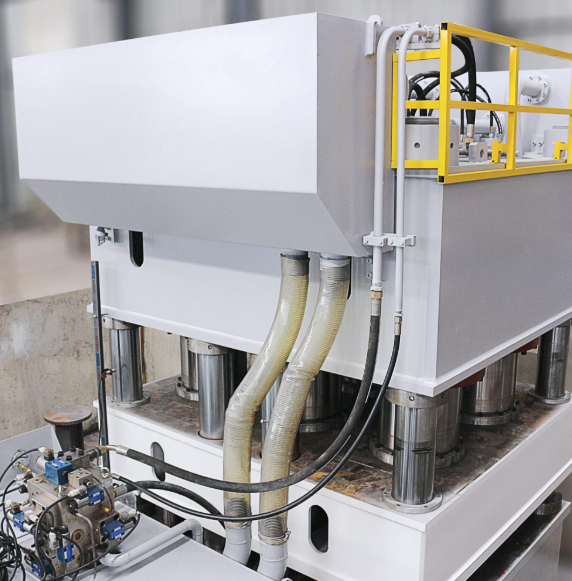

The Harsle 3000T Door Embossing Machine is a high-capacity, industrial-grade machine engineered to deliver detailed, deep, and precise embossing on a variety of door materials. With an impressive 3000-ton hydraulic system, a large-format worktable, and a sophisticated CNC control system, this machine is built to meet the production demands of both medium-sized workshops and large-scale door manufacturing operations.

Whether you are producing steel security doors, decorative aluminum doors, or premium wood panels with ornate finishes, the Harsle 3000T offers the strength, versatility, and accuracy needed to produce high-quality, high-value products efficiently and reliably.

At the heart of the Harsle 3000T is its powerful hydraulic press capable of generating a massive 3000 tons of pressure. This allows for deep and uniform embossing even on thicker materials and harder metals. The hydraulic system ensures:

Consistent embossing results across the entire surface of the door panel

Capacity to work with a wide range of thicknesses – up to 10 mm for metal and 30 mm for wood

Long-term durability and energy-efficient operation through advanced pressure regulation and return systems

The machine includes a spacious 3000 mm x 1500 mm worktable, accommodating full-sized single or double-door panels with ease. This expansive workspace enables:

Embossing on a wide variety of standard and custom door sizes

Handling of large and heavy materials without compromise on alignment or control

Flexibility for manufacturers who produce both residential and commercial door types

The Harsle 3000T is equipped with a modern CNC control panel and touch-screen interface, which simplifies operations and ensures repeatable accuracy. This system provides:

Easy pattern setup and storage of embossing programs

Precise adjustments for pressure, position, and speed

Reduced setup time between different embossing jobs

Smooth integration into modern production lines with minimal manual input

This embossing machine can process multiple material types, offering manufacturers the ability to expand their production without purchasing separate machines. Compatible materials include:

Steel – commonly used for exterior and security doors

Aluminum – ideal for lightweight, corrosion-resistant doors

Wood – up to 30 mm thick, for intricate carved designs and high-end custom interiors

Tooling flexibility is a standout feature. With interchangeable dies, users can:

Switch between different embossing patterns quickly

Design and install custom tooling for unique door styles

Optimize production for a variety of client requirements, enhancing product offerings

Operators benefit from a straightforward and intuitive interface that reduces training time and increases operational efficiency:

Simple touch-screen controls

Real-time system monitoring and fault diagnostics

Quick adjustments for tooling and material changes

Safety is a key design priority in the Harsle 3000T:

Emergency stop systems and pressure release controls

Hydraulic overload protection

Guarding and light-curtain safety mechanisms

Compliance with international safety standards

Despite its heavy-duty performance, the Harsle 3000T is optimized for energy savings:

Efficient hydraulic system minimizes wastage

Intelligent motor control adjusts power draw according to load

Lower operational costs over long production cycles

For continuous production operations, the machine supports:

Automatic feeding and ejection systems

Reduced manual handling

Seamless integration into door manufacturing production lines

| Model | Harsle 3000T |

|---|---|

| Hydraulic Pressure | 3000 tons |

| Worktable Size | 3000 mm x 1500 mm |

| Material Thickness | Up to 10 mm (metal), 30 mm (wood) |

| Control System | CNC with Touch-Screen Interface |

| Power Supply | 380V/50Hz (customizable by region) |

| Dimensions (L x W x H) | 5000 mm x 2500 mm x 3200 mm |

| Weight | Approx. 25,000 kg |

| Location | China |

The Harsle 3000T is suitable for a wide range of door manufacturing operations:

Produces clean, deep embossing on both plain and patterned doors

Enhances security doors with decorative textures and strength-enhancing designs

Capable of creating traditional and modern carved designs on thick wood panels

Adds luxury and craftsmanship to high-end door collections

Ideal for manufacturers creating unique doors for residential, commercial, or industrial projects

Supports branding, logo embossing, and artistic textures

Advanced CNC control and hydraulic pressure ensure uniform depth and clarity across the embossed area, producing high-end finishes that stand out in the market.

Fast changeover times, programmable settings, and automated functions enable quicker production cycles with reduced labor involvement.

The robust construction and intelligent hydraulic design minimize the need for frequent maintenance, ensuring long operating life and high machine availability.

Whether you are a growing manufacturer or a large production house, the Harsle 3000T can scale with your needs—offering consistent results across thousands of units.

Delivery times depend on your location and preferred method of shipping:

Air Freight: Approximately 7 to 10 days

Sea Freight: Approximately 30 to 45 days for most international destinations

The machine is securely packed and shipped with full installation documentation and optional on-site support.

The Harsle 3000T is competitively priced to provide unmatched value for its size and capabilities. Pricing will vary based on:

Tooling and die configurations

Customization options

Volume orders or automation upgrades

To receive a detailed quote tailored to your requirements, please contact us directly using the details below.

If you are looking for a specific machine or have any technical inquiries, our team is ready to help. With access to a global network, we can help you find the exact machine that fits your production needs.

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Website: [Your Website URL]

The machine supports steel, aluminum, and wood panels. It can emboss up to 10 mm thick metal and up to 30 mm thick wood, offering versatility across different door styles and materials.

Yes, the machine supports interchangeable tooling, and custom dies can be manufactured to meet specific pattern requirements. The CNC system allows for quick programming and setup.

Delivery by air takes around 7 to 10 days. Delivery by sea takes approximately 30 to 45 days, depending on your location.

Routine maintenance includes hydraulic oil checks, die cleaning, and control system calibration. The machine is built for long-term durability with minimal downtime.

Yes, it supports automated feeding and ejection systems and can be integrated into larger workflows for continuous embossing and higher production efficiency.

Basic training and installation instructions are included. Remote or in-person technical support is also available upon request.

The Harsle 3000T Door Embossing Machine represents a perfect blend of power, precision, and production flexibility. With its heavy-duty construction, advanced CNC control, and ability to emboss a wide range of materials, it stands as a reliable solution for manufacturers looking to elevate their door production.

Whether you're aiming to scale your current output, launch a new product line, or improve the quality and customization of your doors, the Harsle 3000T delivers.

Contact Machine Matcher today to find out how this machine can transform your production process.

Copyright 2026 © Machine Matcher.