To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

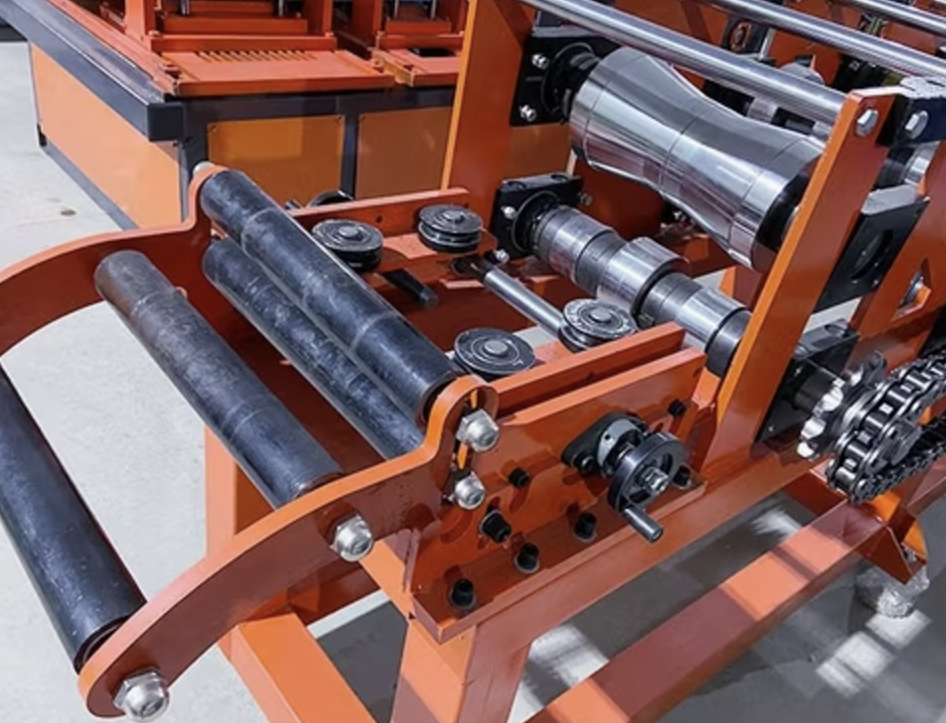

A Hat Channel Roll Forming Machine is designed to manufacture hat-shaped metal channels used extensively in construction, particularly in roofing, walls, and ceilings as structural support or as part of drywall installations. These machines produce channels with precise dimensions, clean cuts, and high consistency, making them ideal for industrial and commercial projects.

The machine utilizes a cold roll forming process, where metal coils are gradually shaped into hat channels through a series of rollers. It can accommodate a wide range of materials, including steel, aluminum, and galvanized steel, depending on the application.

1. What is the typical delivery time for a Hat Channel Roll Forming Machine in Canada?

Delivery times vary but are usually between 6 to 8 weeks, depending on machine customization and supplier location.

2. Can the machine handle multiple profile sizes?

Yes, many Hat Channel Roll Forming Machines can be configured to produce multiple profile sizes, often with quick-change roller setups.

3. What type of material is most commonly used in Canada for hat channels?

Galvanized steel is the most common material due to its durability and corrosion resistance, which is essential in Canada's diverse climate.

4. Are the machines easy to operate?

Yes, they are equipped with user-friendly PLC systems and touchscreen interfaces, making them suitable even for operators with minimal experience.

5. What maintenance is required for the machine?

Routine maintenance includes lubrication of moving parts, inspection of rollers and cutters, and periodic checking of the hydraulic and electrical systems. Most manufacturers provide a detailed maintenance schedule.

6. How energy-efficient are these machines?

Modern Hat Channel Roll Forming Machines are designed to be energy-efficient, aligning with Canadian standards for industrial equipment.

7. Can I get training for operating the machine?

Yes, most suppliers offer on-site or virtual training for machine setup, operation, and maintenance.

8. What is the warranty period?

The warranty typically ranges from 1 to 2 years, covering parts and labor, depending on the manufacturer.

A Hat Channel Roll Forming Machine is an essential investment for Canadian construction businesses seeking to produce high-quality structural components efficiently. With customizable options, compatibility with Canadian standards, and robust features, these machines cater to the growing demand in residential, commercial, and industrial construction.

Copyright 2026 © Machine Matcher.