To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

A Hat Channel Roll Forming Machine is designed to produce hat channels, often used for framing in construction, drywall installation, and other structural applications. Hat channels get their name from their hat-like shape, featuring flanges on both sides, which makes them versatile for mounting and support structures. Below are common specifications and descriptions for this type of machine:

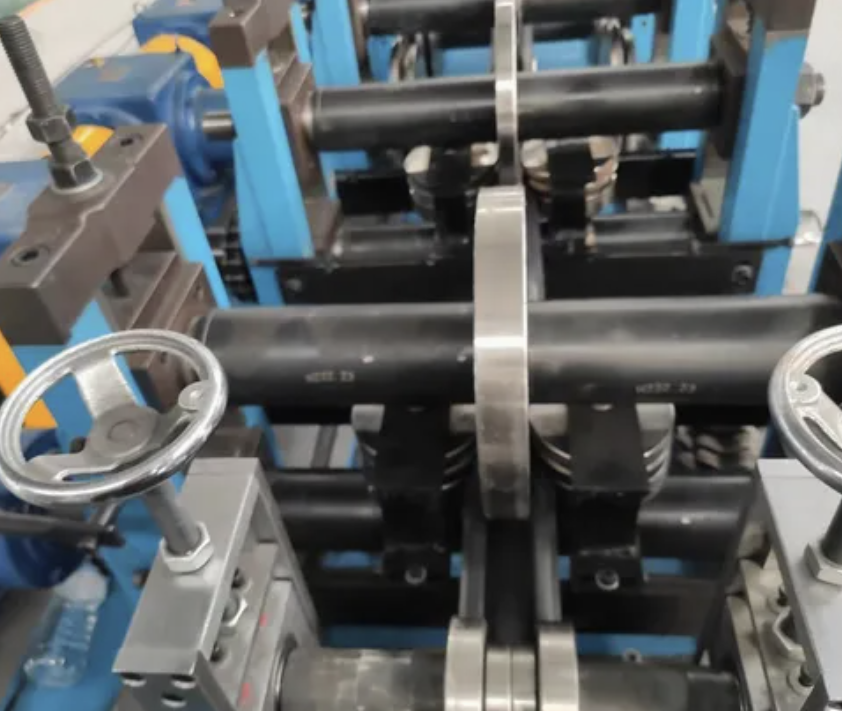

The hat channel roll forming machine is engineered to create consistently shaped channels that conform to construction standards. With advanced roller setups, the machine gradually bends the metal into the required hat profile with flanges on each side. The hydraulic cutting system ensures accurate cutting at the required lengths, while the PLC control allows operators to set different parameters like profile length and quantity for seamless operation. This automation reduces manual input, boosting productivity and precision.

Hat channel roll forming machines are ideal for industries needing high-volume, precise profiles, ensuring that each hat channel is produced with consistent quality and durability.

Copyright 2026 © Machine Matcher.