To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

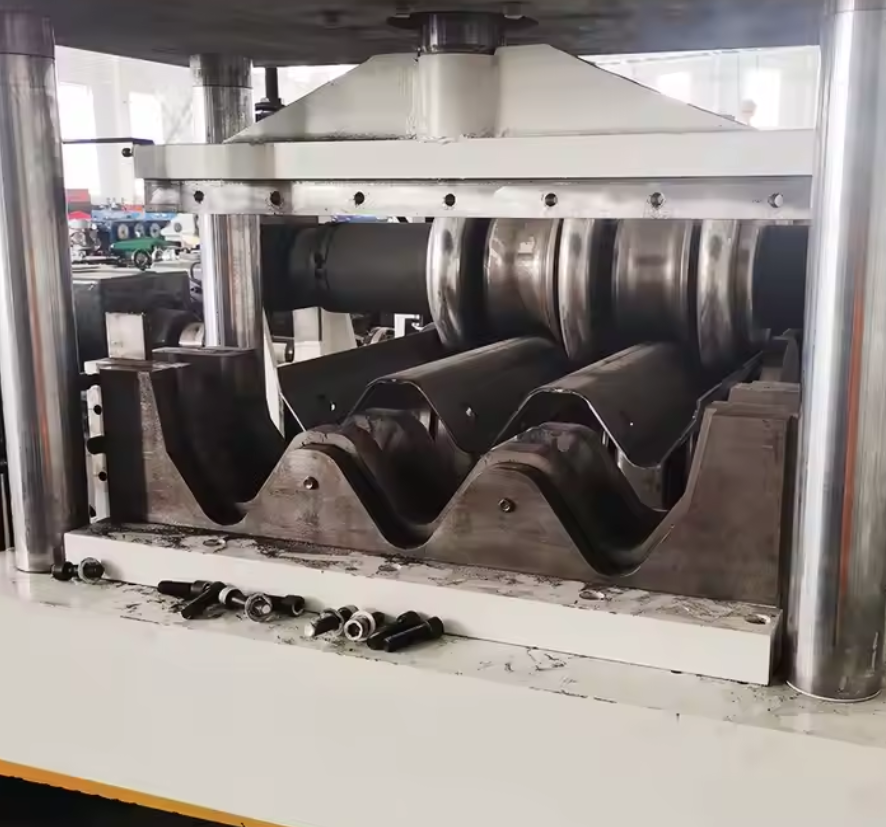

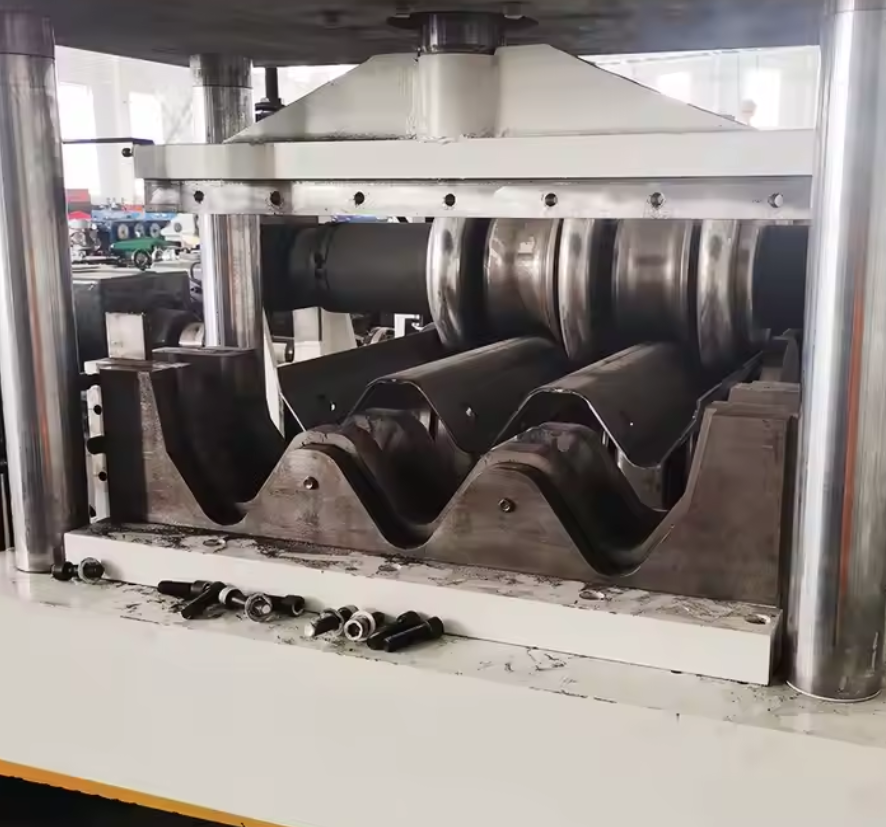

Highway Guard Rail Roll Forming Machine – United Arab Emirates Edition

Custom-Built, High-Capacity Roll Former for Roadway Safety Solutions

The Highway Guard Rail Roll Forming Machine is a high-performance industrial forming system engineered to produce precision W-beam and Thrie-beam highway safety barriers. This robust roll forming machine is designed specifically to cater to the demands of transport infrastructure projects in the United Arab Emirates (UAE) and surrounding GCC countries.

Built to handle heavy-gauge high-tensile steel, this machine delivers superior forming quality, high production speed, and long-term durability, making it ideal for national highway projects, urban road expansion, and infrastructure upgrades throughout Abu Dhabi, Dubai, Sharjah, and beyond.

This machine caters to the following industries:

Transportation Infrastructure

Highway and Road Construction

Municipal Engineering

Defense and Border Security

Oil & Gas Site Road Safety

Designed for continuous production of highway guardrails (W-beam or Thrie-beam)

Integrated hydraulic cutting and punching options

Capable of handling thick, high-strength steel coils

Suitable for highway safety installations, bridge protection barriers, and urban roadside protection fencing

Machine Type: Highway Guard Rail Roll Forming Machine (W-beam / Thrie-beam capable)

Production Speed: 10–20 meters/min (adjustable)

Material Thickness Range: 2.5 – 4.0 mm

Material Width Range: 300 – 600 mm (depending on profile type)

Material Types: Galvanized Steel, Mild Steel, Hot-Dip Galvanized Steel

Material Yield Strength: Up to 550 MPa (80 ksi)

Roller Material: GCr15 hardened steel, heat-treated

Roller Surface Treatment: Chrome-plated for anti-corrosion and smooth forming

Number of Forming Stations: 16–24 (depending on profile)

Roller Shaft Diameter: 80–90 mm

Shaft Material: High-grade 45# steel, precision-ground and quenched

Main Drive Type: Gearbox chain drive

Power (UAE compatible): 380V / 50Hz / 3 Phase

Motor Power: 30–45 kW (depending on configuration)

Cutting Method: Hydraulic cutting with synchronized die set

Blade Material: Cr12Mov, heat-treated

Control Type: PLC automated system with touch-screen HMI

Operating Mode: Fully automatic / semi-automatic options

De-coiling System: Heavy-duty hydraulic uncoiler (5–10 tons capacity)

Punching/Notching System: Hydraulic pre-punching (holes, slots as required)

Machine Frame: Welded steel frame with stress relief treatment

Thickness of Frame Steel: 20–25 mm

Profile Shape: W-beam or Thrie-beam guard rail

Profile Width and Depth: Approx. 310 mm width × 83 mm depth (W-beam) or customized

Length Tolerance: ±2 mm

Safety Features:

Full protective enclosures

Emergency stop button

Overload protection system

Typical Material: Hot-Dip Galvanized Steel or Mild Steel

Material Gauge Range: 10–14 gauge (2.5 mm – 4.0 mm)

Tensile Strength (KSI): 50–80 ksi (up to 550 MPa)

USD $95,000

(Depending on profile type, automation level, punching configuration, uncoiler size, and other optional add-ons)

Number of profiles and tooling sets

Level of automation (basic vs. fully automatic line)

Integrated punching/notching

Hydraulic vs. manual uncoilers

Coil handling systems (optional stackers, car tippers, conveyors)

PLC brand (Siemens, Mitsubishi, etc.)

All machines are custom-built and brand new

Delivered across the UAE, including Abu Dhabi, Dubai, Sharjah, Ajman, and other emirates

Machines are configured to UAE industrial power standards

1-year warranty and technical support included

| Unique Selling Proposition | How It Helps the Buyer |

|---|---|

| Built for High-Tensile Steel | Enables use of heavy-duty materials for long-lasting guardrails |

| UAE-Ready Voltage & Power Configuration | No costly rewiring or compatibility issues |

| Fully Customizable Profile Tooling | Supports local standards and special project specs |

| Pre-Punching & Hydraulic Cutting Integration | Boosts production efficiency and reduces labor cost |

| Industrial-Grade Durability | Long lifecycle with minimal maintenance required |

| Intelligent PLC Control | Easy operation, real-time monitoring, and reduced error margin |

| Chrome-Coated Rollers | Minimizes wear, rust, and surface defects |

Custom profile shapes and sizes (W-beam, Thrie-beam, or proprietary shapes)

Branded control systems (Siemens, Mitsubishi, etc.)

Optional coil handling systems (coil cars, stackers, conveyors)

Remote control PLC and HMI systems

Additional punching dies or hydraulic notching units

If you have:

Profile drawings

Material specifications

Gauge requirements

Target capacity/speed

Send all details to [email protected]

We will get back to you with a tailored machine proposal, optimized for your budget and local standards.

Q1: Can the machine produce both W-beam and Thrie-beam profiles?

A: Yes. With interchangeable tooling, the machine can be configured to roll both types. Let us know in advance which profiles you need.

Q2: How long does it take to manufacture and deliver to the UAE?

A: Standard build and delivery time ranges from 70–90 days, depending on customization and port clearance.

Q3: Do you provide installation and operator training?

A: Yes. We offer on-site installation, commissioning, and operator training in the UAE through our technical support team or partners.

Q4: Can the machine handle galvanized steel with 80 ksi yield strength?

A: Absolutely. The machine is designed to handle up to 550 MPa (80 ksi) tensile strength steel.

Q5: What is the warranty period?

A: All machines include a 1-year warranty from date of dispatch. We also offer long-term maintenance and spare parts support.

For UAE highway projects or regional infrastructure needs, this roll forming solution is a proven investment in safety, efficiency, and performance.

Contact Machine Matcher today for your custom-built guard rail forming machine.

Copyright 2026 © Machine Matcher.