To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

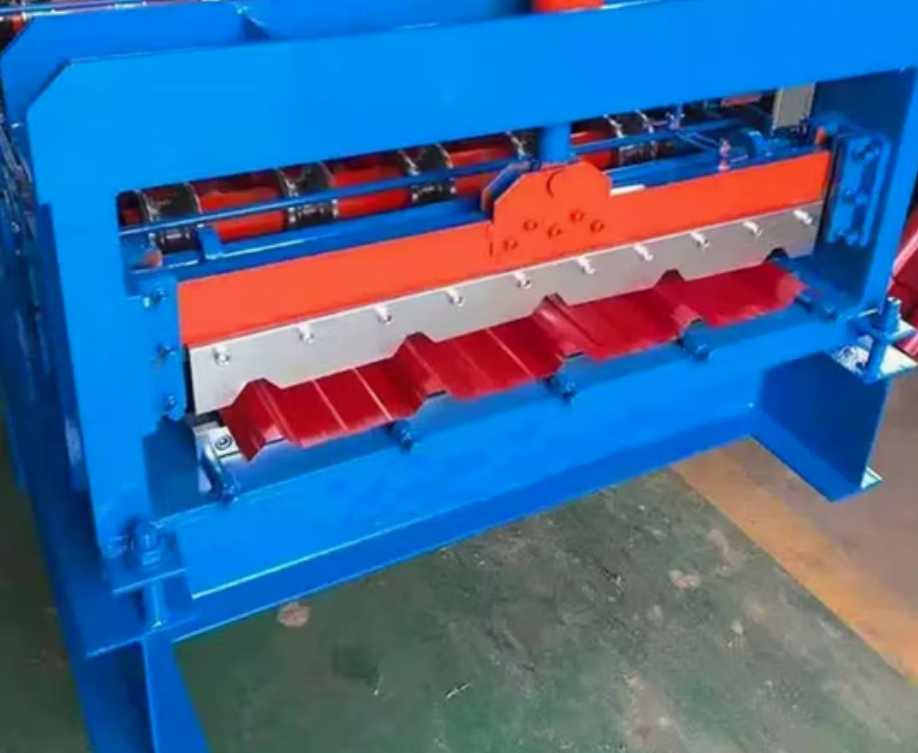

The IBR roll forming machine is one of the most in-demand metal roofing machines in Angola, widely used in the construction of commercial, residential, and industrial buildings. This machine produces the IBR (Inverted Box Rib) roofing sheet — a high-strength, low-maintenance profile known for its superior load-bearing capacity, weather resistance, and long-lasting performance.

Machine Matcher supplies new, custom-built IBR roll forming machines designed to meet the exact requirements of Angolan buyers — including local power supply (380V, 50Hz), preferred coil sizes, and roof profile standards common across Luanda, Benguela, Huambo, and Lubango.

All machines are manufactured to order, with options for automation, punching, embossing, and hydraulic cutting systems.

Machine Type: IBR Roof Panel Roll Forming Machine

Production Speed: 12–20 meters per minute (adjustable up to 30 m/min with servo drive)

Material Thickness Range: 0.3 – 0.8 mm

Material Width Range: 925 – 1220 mm (customizable)

Material Types: Galvanized steel, pre-painted steel, aluminum, galvalume

Material Yield Strength: 235 – 550 MPa

Roller Material: GCr15 high-grade steel

Roller Surface Treatment: Hard chrome plating (0.05 mm)

Number of Forming Stations: 16–22 depending on profile

Roller Shaft Diameter: 70 – 85 mm

Shaft Material: 45# steel, heat-treated

Main Drive Type: Chain drive or gearbox (optional for higher precision)

Power Supply: 380V / 50Hz / 3-phase (customizable for Angola)

Motor Power: 7.5 – 11 kW main motor

Cutting Method: Hydraulic post-cutting or flying shear (optional)

Blade Material: Cr12Mov steel, heat treated

Control Type: PLC control system (Delta, Siemens, or Mitsubishi)

Operating Mode: Fully automatic with touch-screen HMI

De-coiling System: 5-ton manual or hydraulic uncoiler

Punching/Notching System: Optional inline hydraulic punching system

Machine Frame: 350 H-beam welded steel structure

Thickness of Frame Steel: 16–20 mm

Profile Shape: IBR roofing sheet (customizable rib height and pitch)

Profile Width and Depth: Common size 686 mm cover width, 36 mm rib height

Length Tolerance: ±1.5 mm per 6 meters

Safety Features:

Full protective guards and covers

Emergency stop system

Overload and over-temperature protection

Automatic hydraulic decoiler and recoiler systems

Stacking and counting system

Embossing rollers for decorative finish

Servo feeder for high-precision feeding

Remote PLC monitoring and diagnostics

Automatic coil car tipper and leveling systems

Extended run-out tables (6–10 meters)

The IBR roofing profile is a popular standard across Southern Africa, known for its trapezoidal shape with deep ribs and wide pans.

Profile Material Options:

Galvanized steel

Aluzinc

Aluminum

Color-coated steel

Profile Sizes (Typical):

Overall width: 925–1220 mm

Effective cover width: 686 mm

Rib height: 36–38 mm

Pitch: 171–175 mm

Applications:

Residential roofing

Commercial warehouses

Agricultural sheds

Industrial buildings

Public infrastructure projects

Industries Using IBR Panels:

Construction, building materials, prefabricated housing, and roofing contractors throughout Angola.

Entry-level IBR roll former: from USD 25,000 – 35,000

Mid-range automatic model: USD 45,000 – 65,000

High-speed or servo model with stacker: USD 75,000 – 95,000+

(Prices vary depending on configuration, automation, and optional extras. Contact Machine Matcher for a customized quotation.)

Each machine is delivered fully tested and pre-commissioned before shipping. Installation includes:

Foundation and alignment check

Electrical and hydraulic connections

PLC calibration and safety tests

Operator training (on-site or remote)

Machine Matcher provides remote PLC support and Angola-based installation guidance to ensure a smooth start-up.

Routine maintenance ensures long-term reliability:

Daily: Check oil levels and clean rollers

Weekly: Inspect chains and lubricate moving parts

Monthly: Calibrate sensors and check blade sharpness

Annually: Replace hydraulic oil, inspect bearings, and check motor alignment

Machine Matcher’s Technical Support Desk can help with remote diagnosis, spare-parts supply, and maintenance planning.

Q1: What is an IBR roll forming machine used for?

A: It’s used to produce IBR roof sheets — a high-strength trapezoidal panel commonly used across Africa for roofing and cladding applications.

Q2: Can the IBR profile be customized for my local market?

A: Yes, the rib height, width, and pitch can all be customized according to your profile drawing or local roofing standards.

Q3: What materials can the IBR machine work with?

A: It can process galvanized, galvalume, aluminum, and color-coated steel sheets ranging from 0.3–0.8 mm thick.

Q4: Is the IBR roll former suitable for Angola’s power supply?

A: Yes. Machines are configured for 380V, 50Hz, 3-phase supply, common across Angola.

Q5: Do you provide installation and operator training?

A: Yes. Machine Matcher offers remote and on-site setup assistance, operator training, and lifetime technical support.

Machine Matcher supplies new, custom-built roll forming machines tailored for Angola’s construction market.

Built to your profile and coil specs

Worldwide shipping and installation support

24/7 technical assistance and spare-parts supply

UK and USA-based engineering teams

Machines are tested, certified, and built for longevity

For pricing, drawings, and technical consultation, contact:

Machine Matcher

United Kingdom (Main Office)

Phone: +44 20 335 56554

United States

Phone: +1 407 559 7948

Mobile / WhatsApp: +44 7816 972935

Email: [email protected]

Copyright 2026 © Machine Matcher.