To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

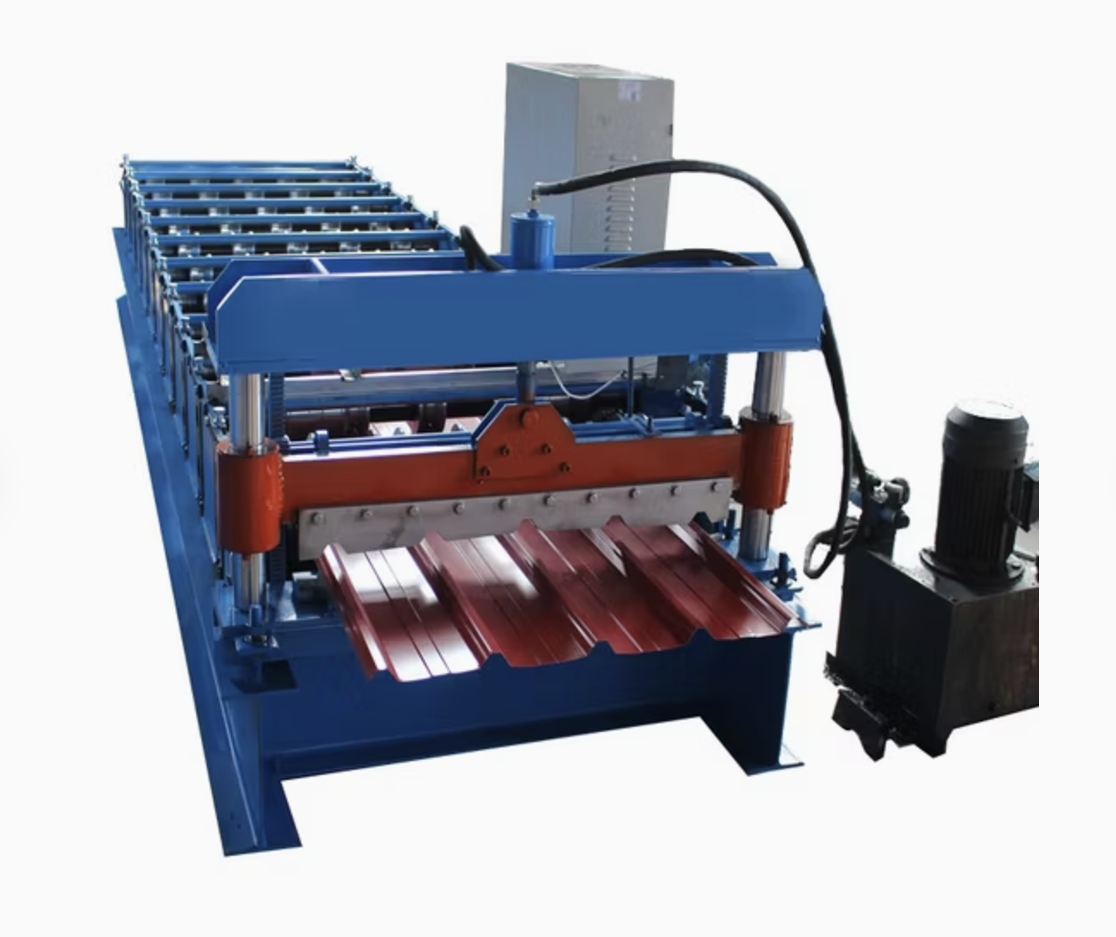

The IBR (Inverted Box Rib) roll forming machine is a specialized piece of equipment used for manufacturing IBR roof sheets. These sheets are widely used in residential, commercial, and industrial buildings in Brazil due to their durability, aesthetic appeal, and ability to withstand the region's diverse weather conditions.

The machine is engineered to produce high-quality roofing sheets efficiently, catering to the growing demand in construction and infrastructure projects in Brazil. With advanced features and customizability, it is ideal for both small and large-scale manufacturing operations.

Q: What is the production capacity of an IBR roll forming machine?

A: The production capacity depends on the machine's speed and the thickness of the material. Standard machines produce up to 500-700 square meters per hour.

Q: Can the machine handle multiple profiles?

A: Yes, some machines can be customized or equipped with interchangeable rollers to produce multiple profiles.

Q: How does the machine handle power fluctuations in Brazil?

A: The machine includes a voltage stabilizer and protection systems to manage power fluctuations common in some Brazilian regions.

Q: What are the shipping and installation options for Brazil?

A: Machines can be shipped via sea freight to Brazilian ports. Installation and training services are often provided by the supplier or local technicians.

Q: What is the maintenance requirement for the IBR roll forming machine?

A: Regular lubrication of moving parts, checking and tightening bolts, and cleaning rollers are essential. Annual inspections of electrical components and hydraulic systems are recommended.

Q: How customizable are the IBR profiles?

A: Profiles can be customized to meet specific market demands, including rib height, sheet width, and material type.

Q: Are there any certifications required for the machine in Brazil?

A: Machines imported to Brazil must comply with ANVISA and ABNT regulations, ensuring safety and quality standards.

An IBR roll forming machine is an excellent investment for businesses in Brazil’s construction and roofing industry. With its versatility, efficiency, and ability to produce durable roofing sheets, it supports the growing demand for quality infrastructure in the country.

For buyers in Brazil, it is crucial to consider factors like material thickness, power requirements, and machine speed to choose the right equipment. Collaborating with reputable suppliers and ensuring compliance with local standards will ensure a smooth purchasing and operational experience.

Copyright 2026 © Machine Matcher.