To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

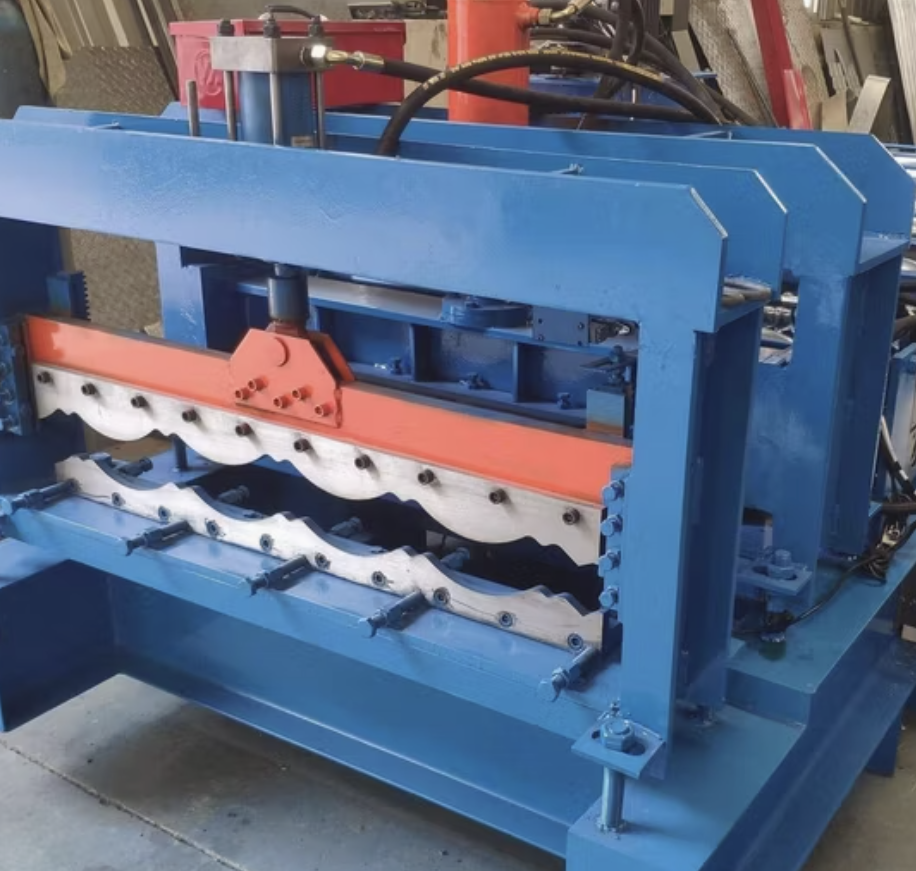

An IBR Roll Forming Machine is a specialized equipment designed to produce IBR (Inverted Box Rib) roofing sheets, a popular roofing profile widely used in residential, commercial, and industrial applications. Known for its durability, excellent water-shedding capability, and aesthetic appeal, the IBR profile is especially popular in regions like Africa, Asia, and South America.

This roll forming machine transforms coiled steel into precisely cut IBR roofing sheets with consistent accuracy. Equipped with advanced systems for punching, cutting, and profiling, it ensures high productivity, low waste, and superior quality output.

The machine is shipped pre-assembled and requires minimal on-site installation. Basic setup involves:

Q1: What materials can be used with an IBR Roll Forming Machine?

A1: It supports galvanized steel, pre-painted steel, aluminum, and mild steel coils within a thickness range of 0.3mm to 0.8mm.

Q2: Can the machine produce custom IBR profiles?

A2: Yes, the machine can be customized to produce different rib heights, spacings, and sheet widths as per client requirements.

Q3: Is the machine suitable for high-volume production?

A3: Absolutely. With production speeds ranging from 10 to 30 meters per minute, it is ideal for large-scale roofing projects.

Q4: Does the machine support automation?

A4: Yes, it comes with a fully automated PLC control system for precise operations, reduced manual intervention, and higher efficiency.

Q5: How long does it take to install the machine?

A5: Installation typically takes 2-3 days, depending on site readiness and the complexity of optional extras.

Q6: What safety features are included?

A6: The machine includes emergency stop buttons, protective guards, and safety alarms to ensure operator safety.

Q7: What is the typical lifespan of an IBR Roll Forming Machine?

A7: With proper maintenance, the machine can operate efficiently for over 10 years.

Q8: Can IBR Roll Forming Machines handle painted coils without damaging the finish?

A8: Yes, the chrome-coated rollers and precision profiling ensure the surface finish remains intact during production.

Q9: Are there different power supply options?

A9: The machine can be configured for different voltage and frequency requirements, such as 380V/50Hz or 220V/60Hz, based on the buyer's region.

Q10: Can I upgrade the machine later with extras like a stacker or remote PLC system?

A10: Yes, the machine design allows for modular upgrades, ensuring flexibility as your production needs grow.

Copyright 2026 © Machine Matcher.