To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

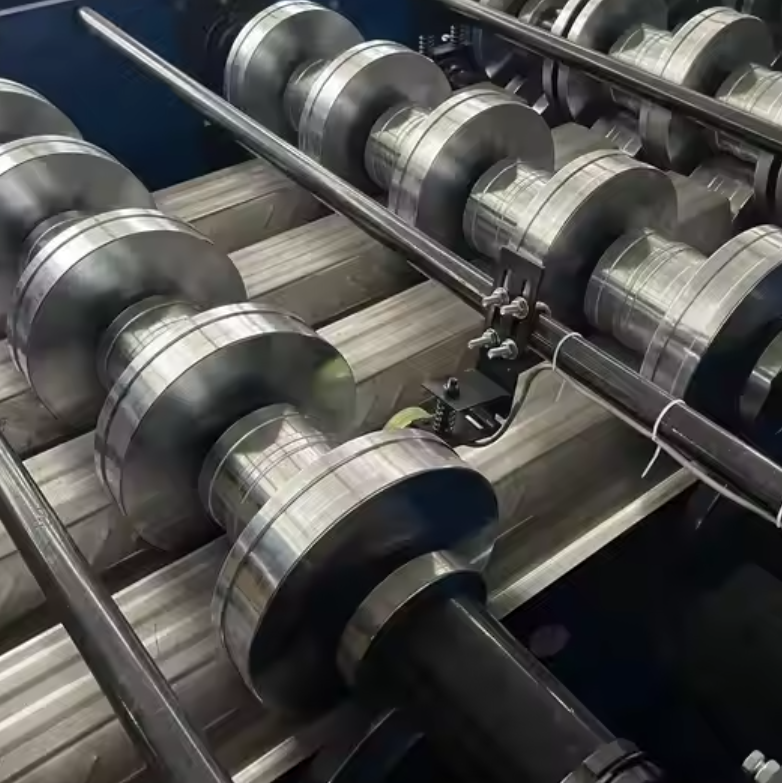

Intermediate Rib Deck Roll Forming Machine – UAE Edition

Efficient, Accurate, and Built for the UAE Construction Sector

The Intermediate Rib Deck Roll Forming Machine is a precision-engineered system designed for producing high-strength, intermediate ribbed steel decking sheets used in commercial and industrial construction. Built to withstand the heat and demanding requirements of the UAE market, this machine is capable of processing various thicknesses of galvanized and high-tensile steel to form decking profiles ideal for concrete floor reinforcement and steel frame structures.

This machine is suited for use in high-rise buildings, shopping malls, warehouses, airports, stadiums, and infrastructure projects across the UAE. It provides a reliable solution for manufacturers, steel fabricators, and construction contractors looking for consistent production quality and minimal downtime.

Machine Type: Intermediate Rib Deck Roll Forming Machine

Production Speed: 15–25 meters per minute (adjustable based on material and profile)

Material Thickness Range: 0.8mm – 1.5mm

Material Width Range: 1000mm – 1250mm

Material Types: Galvanized Steel (GI), Cold Rolled Steel (CR), Galvalume Steel

Material Yield Strength: Up to 550 MPa

Roller Material: GCr15 (high-grade bearing steel)

Roller Surface Treatment: Hard chrome-plated to reduce wear and ensure profile smoothness

Number of Forming Stations: 18–24 stations (customizable based on profile)

Roller Shaft Diameter: 75mm

Shaft Material: 45# steel, precision-ground and quenched

Main Drive Type: Chain drive or gearbox drive (based on customer preference)

Power (UAE compatible): 380V / 50Hz / 3 Phase

Motor Power: Approx. 15kW – 22kW depending on configuration

Cutting Method: Hydraulic cutting with post-cut system (after forming)

Blade Material: Cr12Mov (heat-treated) for long service life

Control Type: PLC system (Siemens, Delta, or Mitsubishi based on customer choice)

Operating Mode: Fully automatic with touch screen HMI interface

De-coiling System: Hydraulic or manual uncoiler (3–10 tons capacity)

Punching/Notching System: Optional inline system for shear connectors or lifting holes

Machine Frame: Welded structure using H-beam steel

Thickness of Frame Steel: 20mm – 30mm

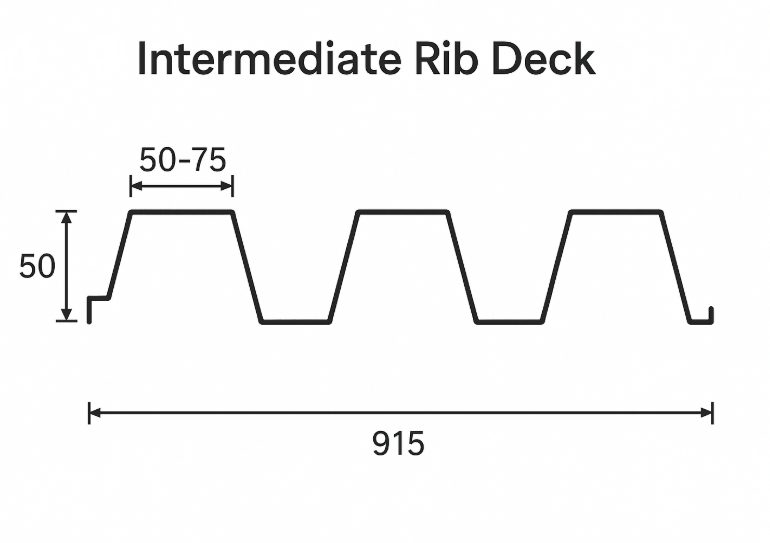

Profile Shape: Intermediate Rib Floor Deck Profile

Profile Width and Depth: Effective Width: Approx. 915mm; Rib Depth: 50–75mm

Length Tolerance: ±2mm for each cut length

Safety Features:

Protective Covers/Guards over moving parts

Emergency Stop Button (multiple stations)

Overload Protection System integrated with drive motor and hydraulics

This Intermediate Rib Deck machine is ideally suited for:

Commercial Buildings: Office towers, malls, car parks

Industrial Facilities: Warehouses, logistics hubs, factories

Infrastructure Projects: Airports, seaports, transit hubs

Pre-engineered Building Systems (PEBs): Steel frame buildings needing floor decking

The UAE’s fast-paced construction industry, especially in cities like Dubai, Abu Dhabi, and Sharjah, demands machines that can meet high standards of safety, speed, and profile accuracy—this machine delivers exactly that.

Starting Price: From USD $65,000

(depending on profile complexity, motor and drive system, and additional systems included)

Choice of PLC brand (Siemens, Mitsubishi, etc.)

Manual vs hydraulic uncoiler

Addition of punching/notching systems

Profile customization or multiple profile setups

Optional stacker systems for finished sheet handling

Required output speed or special tolerance requirements

For a precise quotation, send your deck profile drawing, gauge range, width, and power requirements to:

[email protected]

All machines are brand new, built to order, and can be delivered anywhere in the UAE including Abu Dhabi, Dubai, Sharjah, Ajman, Fujairah, Ras Al Khaimah, and Umm Al Quwain.

Machine Matcher offers full support including:

One-year warranty from date of dispatch

Remote installation assistance or on-site setup (as required)

Operator training and maintenance guidance

Ongoing spare part support and inspection service

Q1: Can this machine produce different decking profiles?

A: Yes, it can be configured to produce multiple intermediate rib deck designs if required. A profile change setup or cassette system can be added as an optional extra.

Q2: What’s the average daily output of this machine?

A: Based on an 8-hour shift and average speed of 20 m/min, the machine can produce over 9,000–11,000 linear meters of deck sheet per day depending on sheet length.

Q3: Is operator training available in the UAE?

A: Yes, Machine Matcher offers on-site training, remote video setup assistance, and PDF/manual guides for local operators.

Q4: How durable is the machine in UAE climate conditions?

A: The machine is built with high-temperature resistant electrical components and uses chromed rollers for added durability in dusty and hot environments.

Q5: Can I integrate this machine into a fully automated production line?

A: Yes, we can supply automated stackers, coil handling systems, and material feeders for a complete turnkey solution.

The Intermediate Rib Deck Roll Forming Machine is the ideal choice for manufacturers and contractors in the UAE’s thriving construction sector. Designed with efficiency, adaptability, and regional durability in mind, this machine supports large-scale steel deck production with unmatched accuracy.

To get a personalized quote or to discuss your exact project needs, contact Machine Matcher today at [email protected]. Our team is ready to support you from profile selection to delivery and operation.

Copyright 2026 © Machine Matcher.