To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

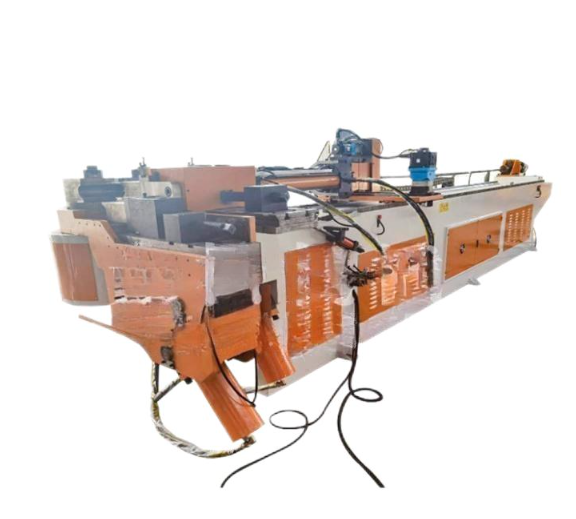

Brand: JSDS

Model: 130CNC

Condition: 100% New

Function: Pipe Bending

Manufacturing Year: 2024

Location: China

The JSDS 130CNC Pipe Bending Machine, engineered and manufactured by WEIBO Machinery, is a high-performance CNC-controlled solution for demanding industrial pipe bending tasks. Designed with precision, power, and productivity in mind, this model represents the latest advancements in automated bending technology for metalworking industries. With a robust frame, cutting-edge CNC interface, and versatile capabilities, the JSDS 130CNC is ideally suited for manufacturers who require consistent accuracy, fast throughput, and flexibility across various pipe materials and bending applications.

Whether you’re producing parts for automotive, aerospace, HVAC, shipbuilding, furniture manufacturing, or general industrial fabrication, this machine offers exceptional value and long-term reliability.

The JSDS 130CNC can handle pipe diameters up to 89mm (approx. 3.5 inches), making it ideal for medium to large-sized pipe fabrication jobs. This high diameter capacity supports a wide range of applications without compromising on accuracy or quality.

Users can configure the bending radius according to specific project requirements, allowing for tight or wide curves based on design needs. This flexibility ensures the machine can adapt to custom product specifications and complex bending geometries.

The integrated Computer Numerical Control (CNC) system automates the bending process, allowing users to pre-program bending angles, radii, and sequences. With this intelligent control system, every bend is executed with high repeatability, reducing errors and rework.

The JSDS 130CNC offers fully automatic or semi-automatic operational modes. Depending on production needs, operators can select the appropriate mode to optimize cycle times and labor efficiency. Automation minimizes human intervention and boosts output quality.

Built with industrial-grade components, this machine features a heavy-duty frame and reinforced structure to withstand continuous operation in demanding environments. The construction ensures long-term stability and minimal vibrations during bending.

To protect operators and maintain compliance with international safety standards, the JSDS 130CNC includes emergency stop buttons, mechanical safety guards, and electrical interlocks. These features help reduce risks associated with high-power mechanical operations.

Compatible with a wide range of pipe materials, including:

Carbon steel

Stainless steel

Aluminum

Copper

Alloy tubes

This material versatility makes the JSDS 130CNC suitable for manufacturers working with various metal grades and requirements.

The machine can perform bending angles across a wide range, including both tight-radius and wide-radius bends. This makes it suitable for standard, complex, or custom-designed pipe components.

Operators can quickly program, adjust, and manage bending sequences using the intuitive CNC interface. The software allows users to input custom parameters, save bending programs, and manage batch production efficiently. It's ideal for both small batches and large-scale operations.

The CNC system combined with precision mechanical components enables tight tolerances and consistent performance over thousands of cycles. Ideal for applications where dimensional accuracy is critical.

Depending on your operational requirements, the JSDS 130CNC can be upgraded with:

Mandrel bending systems for thin-wall pipe support

Advanced programmable logic controllers (PLC)

Multiple bending stack configurations

Tooling upgrades for specific pipe profiles or materials

Discuss available options with your supplier or contact us directly to customize your order.

| Specification | Detail |

|---|---|

| Max Pipe Diameter | 89mm (approx. 3.5 inches) |

| Bending Method | CNC-controlled bending |

| Bending Radius | Adjustable |

| Bending Angle Range | Flexible up to 180° (varies by setup) |

| Material Compatibility | Steel, stainless steel, copper, aluminum |

| Operation Mode | Automatic / Semi-automatic |

| Control Interface | User-friendly CNC system |

| Safety Features | Emergency stop, guards, interlocks |

| Structure | Heavy-duty frame construction |

| Optional Upgrades | Mandrel system, PLC, tooling, etc. |

| Country of Manufacture | China |

| Year of Manufacture | 2024 |

| Condition | 100% New |

The JSDS 130CNC is widely used in industries such as:

Automotive and transportation

Aerospace and aviation

Shipbuilding and marine systems

Furniture manufacturing

HVAC (Heating, Ventilation, Air Conditioning)

Oil and gas pipelines

Structural metal fabrication

Renewable energy systems

Its multi-functional and adaptable design makes it a go-to solution for a broad range of metal processing needs.

We offer international delivery options based on your timeline:

By Air: 7 to 10 days (recommended for urgent deliveries)

By Sea: 30 to 45 days for most destinations (cost-effective for bulk shipments)

All machines are securely packaged for safe transport. Shipping insurance and documentation support can be arranged as required.

Proven Performance: Trusted brand with a reputation for quality

Latest 2024 Technology: Incorporating current-generation CNC and mechanical innovations

Versatility: Works with different materials, radii, and thicknesses

User-Friendly: Designed for skilled and semi-skilled operators alike

Low Maintenance: Built for long-term industrial use with minimal downtime

Excellent Support: Backed by WEIBO Machinery’s technical and customer service

A: The machine can bend pipes up to 89mm in diameter. This makes it suitable for a wide variety of applications in industries like automotive, construction, and energy.

A: Yes, the JSDS 130CNC is compatible with multiple materials, including stainless steel, aluminum, carbon steel, and copper. Material compatibility may depend on the tooling used.

A: No. The machine comes with a user-friendly interface that makes it easy to program, even for operators with limited CNC experience. Training is recommended for optimal use.

A: Yes. The JSDS 130CNC is equipped with essential safety components such as emergency stop buttons, protective guards, and electrical interlocks.

A: Absolutely. We offer optional upgrades like mandrel bending, tooling sets for different diameters, and advanced PLC systems. Let us know your needs, and we’ll customize accordingly.

A:

By air: approximately 7–10 days

By sea: around 30–45 days, depending on your location

We can coordinate with freight forwarders and help you with customs documentation.

A: The JSDS 130CNC Pipe Bending Machine is manufactured and shipped from China.

A: Support options include remote assistance, spare parts, installation guides, and, where needed, on-site support through our global partners or representatives.

If you're looking for a specific pipe bending machine or need help choosing the right equipment for your application, our team at Machine Matcher is ready to assist. We work with a global network to find the best machine for your needs and budget.

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Looking to invest in reliable and accurate pipe bending solutions? The JSDS 130CNC is your answer — delivering precision, power, and performance with every bend.

Copyright 2026 © Machine Matcher.