To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

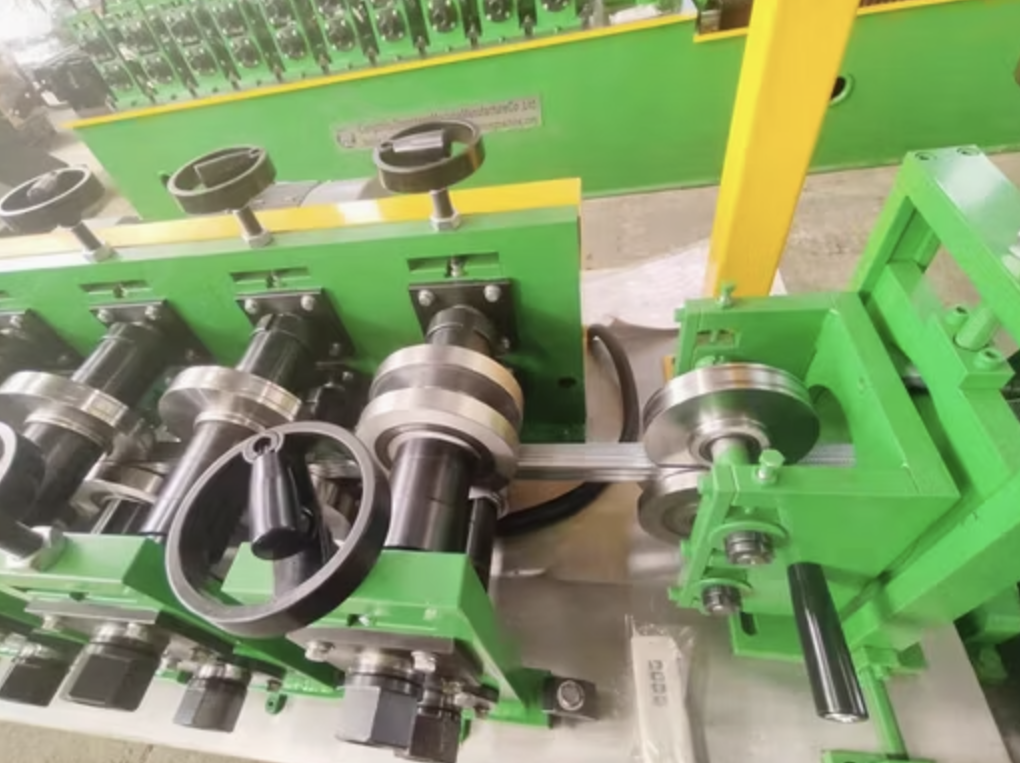

Light gauge roll forming machines are specialized equipment designed for creating lightweight yet durable metal profiles used in construction, automotive, and various industrial applications. These machines are essential in producing consistent, high-quality profiles such as studs, tracks, and other framing components. This guide provides a detailed overview of light gauge roll forming machines, focusing on their specifications, benefits, and usage in Canada.

A light gauge roll forming machine is designed to process thin sheets of metal into precise profiles. The machine operates with high efficiency and precision, catering to industries requiring lightweight and structurally sound components. It features advanced technology for seamless production, ensuring compliance with Canadian building codes and standards.

Light gauge roll forming machines are widely used across Canada for various purposes, including:

With a focus on sustainability and compliance with Canadian standards, these machines support eco-friendly practices by reducing material wastage and optimizing production efficiency.

A1: These machines can process a variety of materials, including galvanized steel, aluminum, stainless steel, and pre-painted steel, with thicknesses ranging from 0.3 mm to 1.5 mm.

A2: Yes, most light gauge roll forming machines come with adjustable tooling to produce various profile shapes, widths, and sizes.

A3: Canadian industries commonly use a 600V/60Hz power supply. Ensure the machine matches your facility's electrical setup.

A4: These machines are equipped with safety guards, emergency stop buttons, and a user-friendly interface to minimize risks.

A5: Regular maintenance includes lubricating moving parts, checking the roller alignment, inspecting the hydraulic system, and cleaning the cutting blades.

A6: Machines are typically shipped in disassembled form and require professional installation. Canadian distributors often provide on-site setup and training services.

Light gauge roll forming machines are a cornerstone of modern industrial and construction practices in Canada. Their ability to produce high-quality, lightweight profiles efficiently makes them an indispensable tool for various industries. When selecting a machine, consider specifications, power requirements, and customization options to ensure it meets your operational needs.

Copyright 2026 © Machine Matcher.