To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

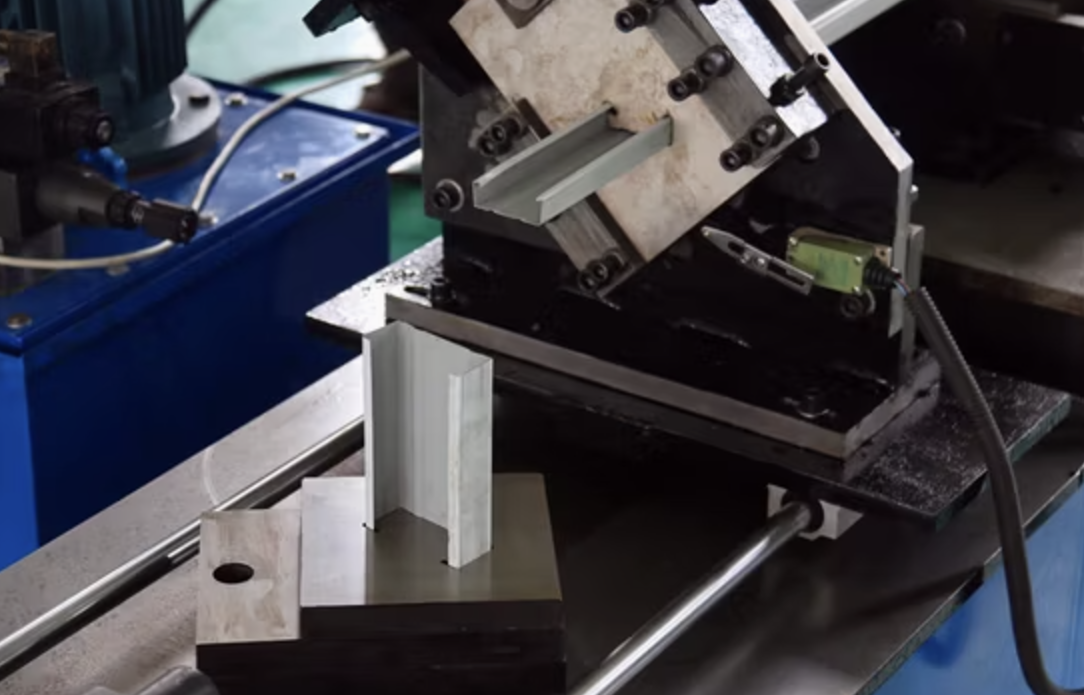

Light gauge roll forming machines are critical in manufacturing thin yet strong profiles for construction and other industries. These machines are ideal for producing metal profiles such as steel studs, tracks, and channels used in lightweight steel framing systems. They are engineered for high-speed production, precision, and durability, making them a preferred choice in South Africa's growing construction and manufacturing sectors.

A light gauge roll forming machine is designed to handle materials with thicknesses ranging from 0.3mm to 1.5mm, commonly referred to as light gauge steel. These machines transform steel coils into custom shapes through a series of precisely aligned rollers.

Key features of the machine include:

| Feature | Details |

|---|---|

| Material Thickness | 0.3mm to 1.5mm |

| Material Types | Galvanized steel, stainless steel, aluminum, and pre-painted steel |

| Roller Material | GCr15 steel, heat-treated for durability |

| Number of Rollers | 10-24 stations (varies by machine type) |

| Cutting Mechanism | Hydraulic cutting system with high precision |

| Machine Speed | 15-30 meters per minute (can vary with customization) |

| PLC System | Siemens or Mitsubishi PLC with touchscreen interface |

| Drive System | Servo motor or gear-driven system |

| Power Supply | 380V/50Hz (customizable to South African standards) |

| Dimensions | 6-12 meters in length, depending on configuration |

| Weight | 5-12 tons |

| Optional Features | Automatic stackers, decoilers, coil car tippers, and punching systems |

Light gauge roll forming machines are widely used in South Africa's construction and manufacturing industries. Typical applications include:

Q1: What types of profiles can a light gauge roll forming machine produce?

A: It can produce C-studs, U-tracks, Z-channels, ceiling channels, and custom profiles for lightweight steel framing.

Q2: What is the typical production speed?

A: Most machines can produce profiles at a speed of 15-30 meters per minute, depending on the complexity of the profile.

Q3: What materials are compatible with this machine?

A: Compatible materials include galvanized steel, stainless steel, aluminum, and pre-painted steel with thicknesses ranging from 0.3mm to 1.5mm.

Q4: Can the machine be customized for South African standards?

A: Yes, the machine can be customized for South Africa’s power supply (e.g., 380V/50Hz) and specific profile requirements.

Q5: Is it easy to install and operate?

A: Yes, the machine comes with a detailed installation guide and training for operators. The PLC system simplifies operations.

Q6: How often should maintenance be performed?

A: Routine maintenance, such as cleaning and lubrication, should be performed weekly, while detailed inspections are recommended every 500 operational hours.

Q7: What are the power requirements for this machine?

A: The standard power requirement is 380V/50Hz, but it can be customized as needed.

Q8: Can I produce profiles for export?

A: Absolutely. The profiles produced meet international standards and can be exported globally.

Copyright 2026 © Machine Matcher.