To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Light gauge roll forming machines are essential equipment in the construction and manufacturing industries, especially for fabricating components like steel framing, roofing panels, and other light structural profiles. In Spain, where the construction market emphasizes precision, sustainability, and cost-efficiency, these machines have gained significant traction.

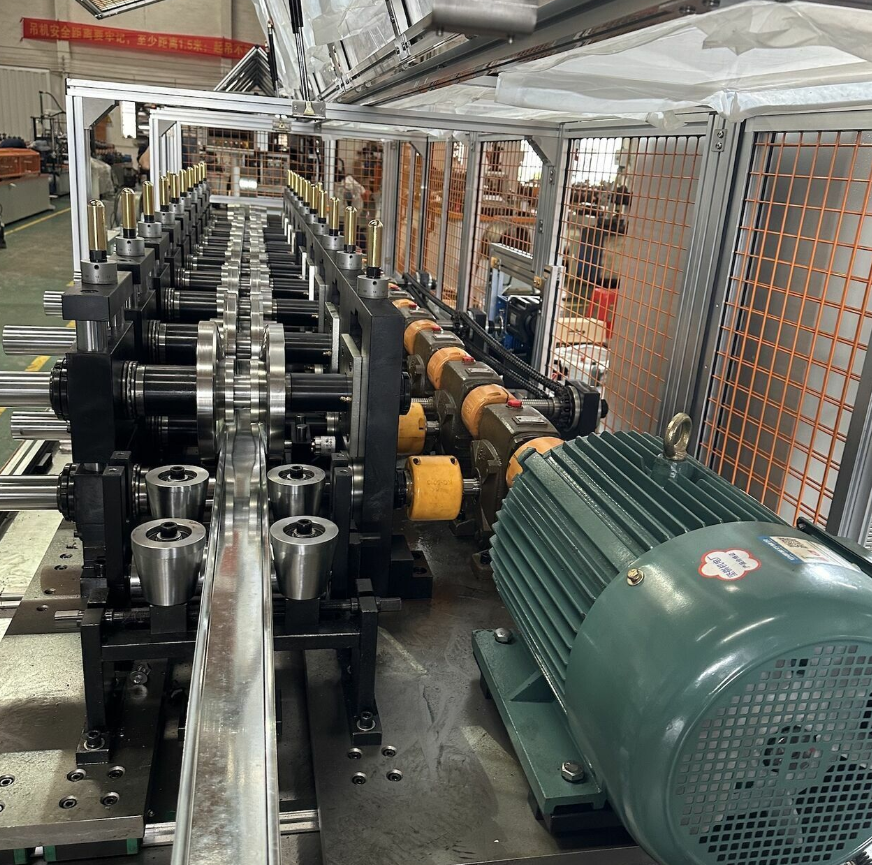

A light gauge roll forming machine is designed to manufacture profiles from thin and lightweight materials, typically ranging from 0.3 mm to 1.2 mm in thickness. These machines are ideal for producing components for light steel framing systems, drywall channels, roof panels, and other similar applications.

| Feature | Details |

|---|---|

| Roller Material | High-strength steel with chrome plating |

| Material Thickness | 0.3 mm to 1.2 mm |

| Frame Size | Heavy-duty steel, reinforced for durability |

| Motor Type | Servo motors for high precision |

| Hydraulic Cutting System | Ensures burr-free, clean cuts |

| Machine Speed | 15-50 meters per minute, adjustable |

| Control System | PLC system with touchscreen interface |

| Power Supply | Customizable (220V/380V/440V) for Spain’s grid |

| Safety Features | Enclosed safety guards, emergency stop buttons |

| Optional Add-ons | Punching and notching systems, stackers |

Yes, light gauge roll forming machines can be customized to produce profiles specific to your project needs, whether for steel framing or roofing applications.

Absolutely. Machines can be configured for Spain’s common power requirements, including 220V and 380V three-phase supplies.

Prices range from €25,000 to €100,000 depending on machine specifications, optional add-ons, and automation levels.

Typically, setup and installation take 1-2 days, depending on the complexity and operator familiarity.

Yes, several suppliers offer these machines in Spain, and many provide installation, training, and maintenance services.

Copyright 2026 © Machine Matcher.