To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Light Gauge Steel Frame Roll Forming Machine – United Arab Emirates

Engineered for Precision, Built for Speed – Designed for UAE Construction and Prefab Industries

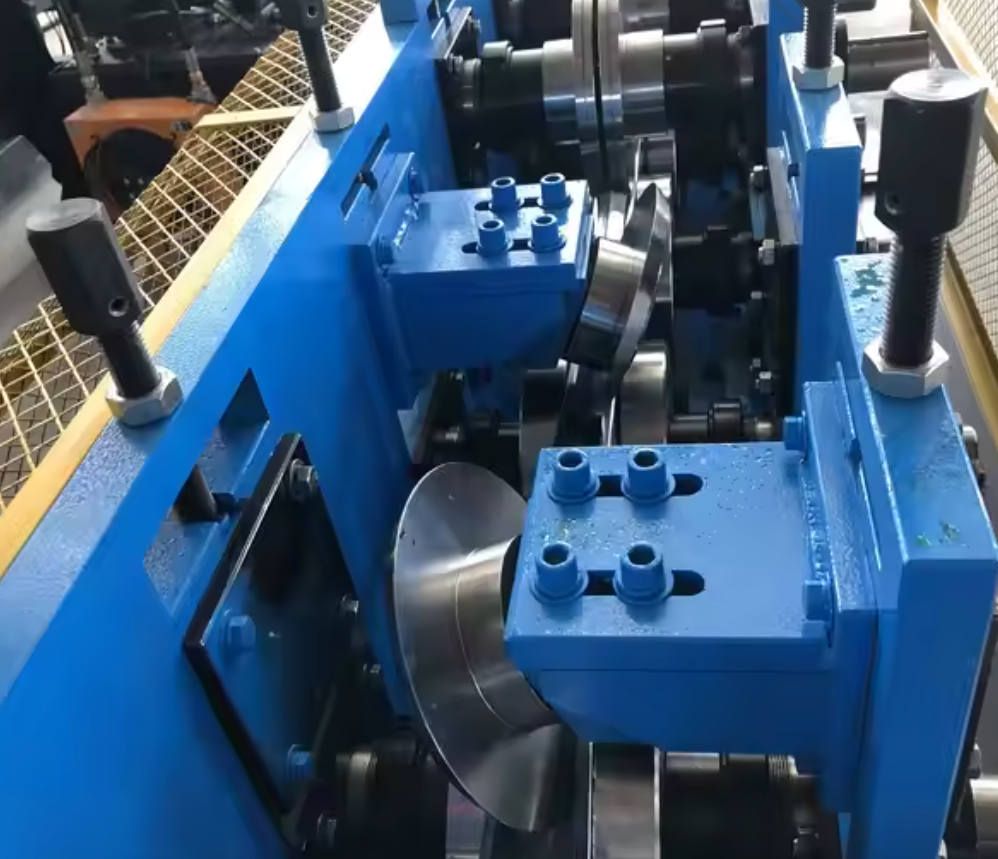

The Light Gauge Steel (LGS) Frame Roll Forming Machine is a high-performance, precision roll forming system designed to manufacture cold-formed steel studs, tracks, and structural profiles used in modern construction frameworks. Ideal for projects throughout the United Arab Emirates, this machine supports UAE’s fast-paced building industry, including residential, commercial, and modular construction.

Engineered with advanced automation and high-accuracy servo systems, this machine produces ready-to-frame light gauge steel profiles with superior dimensional consistency. Perfectly suited for building sites across Abu Dhabi, Dubai, Sharjah, and beyond, the machine supports high-speed production of framing members directly from coil to cut-to-length profiles.

Construction & Contracting (Residential/Commercial/Industrial Framing)

Prefab & Modular Building Manufacturers

Interior Fit-Out Companies

Steel Frame Fabricators

Cold-formed Building Suppliers

Disaster Relief/Temporary Structure Providers

Example Applications:

Steel wall studs and tracks

Ceiling joists

Truss components

Pre-cut panels for modular and prefab housing

Temporary shelters and site cabins

| Specification | Details |

|---|---|

| Machine Type | Light Gauge Steel Frame Roll Forming Machine |

| Production Speed | 15–30 meters/min (adjustable) |

| Material Thickness Range | 0.6 – 2.0 mm |

| Material Width Range | 50 – 300 mm (depending on profile) |

| Material Types | Galvanized Steel, Galvalume, Cold Rolled Steel |

| Material Yield Strength | Up to 550 MPa (80 ksi) |

| Roller Material | GCr15 (hardened steel) |

| Roller Surface Treatment | Hard chrome plating |

| Number of Forming Stations | 12–20 stations (customizable) |

| Roller Shaft Diameter | 60 mm |

| Shaft Material | 45# steel, precision ground and hardened |

| Main Drive Type | Chain drive or gearbox (optional) |

| Power for UAE | 380V / 3 Phase / 50Hz |

| Motor Power | 7.5 – 15 kW |

| Cutting Method | Hydraulic cutting |

| Blade Material | Cr12Mov, heat treated |

| Control Type | PLC + Touchscreen HMI |

| Operating Mode | Automatic with manual override |

| De-coiling System | Manual or hydraulic uncoiler (optional motorized version) |

| Punching/Notching System | Servo punching and inline notching (optional) |

| Machine Frame | H-Beam welded and stress relieved |

| Thickness of Frame Steel | 20–25 mm |

| Profile Shape | U, C, Z, or custom shape |

| Profile Width and Depth | Customizable up to 300 mm width |

| Length Tolerance | ±0.5 mm |

| Safety Features | Emergency Stop, Guard Covers, Overload Protection, Warning Lights |

Galvanized Steel Coil (G550)

Thickness: 0.8 – 2.0 mm

Yield Strength: 280–550 MPa (40–80 ksi)

Cold Rolled Steel

Typically used for interior framing systems

Starting at: USD $55,000

(FOB Factory, depending on configuration and optional features)

What Affects the Final Price?

Custom profile requirements

Number of punching stations

Motorized decoilers, stackers, or coil cars

Advanced automation and remote control options

Profile tooling complexity

Contact [email protected] for a tailored quote. Include any profile drawings or special production details for faster processing.

All machines are brand-new and custom-built based on your production needs.

We deliver anywhere across the United Arab Emirates, including Dubai, Abu Dhabi, Sharjah, Ajman, and other emirates. Machines are built to specification and shipped directly from our certified global manufacturing partners.

Full Automation: Reduces labor cost and human error.

Quick Setup & Changeover: Ideal for multiple profile projects.

Robust Frame & Long Life: Built for UAE heat and high-volume conditions.

Customizable Tooling: Match exact profile sizes without additional processing.

Local Voltage & Compliance: Pre-configured for UAE industrial environments.

Smart PLC System: Integrated touchscreen for easy operation and diagnostics.

How this helps you:

Faster production, minimal waste, high precision, and fewer reworks mean lower total project costs and quicker ROI for your factory.

Multi-profile tooling system

Motorized uncoiler (3T to 10T capacity)

Servo punching with pattern flexibility

Automatic stacker and cross-conveyor

Remote access diagnostics

Profile marking or labeling station

Built-in framing software integration

If you have:

Profile drawings

Material specifications

Preferred output speed

Special electrical requirements

Email all information to [email protected]

We’ll reply with the best configuration, price, and delivery lead time for your UAE location.

Q: Can this machine handle different profile shapes like C and U studs?

A: Yes, it can be configured to switch between C, U, and other shapes with changeable tooling.

Q: How fast can the machine be delivered to the UAE?

A: Typical production and delivery time is 45–70 days depending on configuration.

Q: Does this machine come with training or installation?

A: Yes, optional installation and training support is available for UAE customers.

Q: Is the machine compatible with UAE industrial standards?

A: Absolutely. All machines are delivered pre-configured for 380V / 3 Phase / 50Hz systems.

Q: What kind of warranty is offered?

A: One-year warranty with full support for maintenance, replacement parts, and remote troubleshooting.

Machine Matcher – Your Global Partner in Roll Forming Excellence

UAE’s trusted supplier for roll forming innovation.

Copyright 2026 © Machine Matcher.