To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

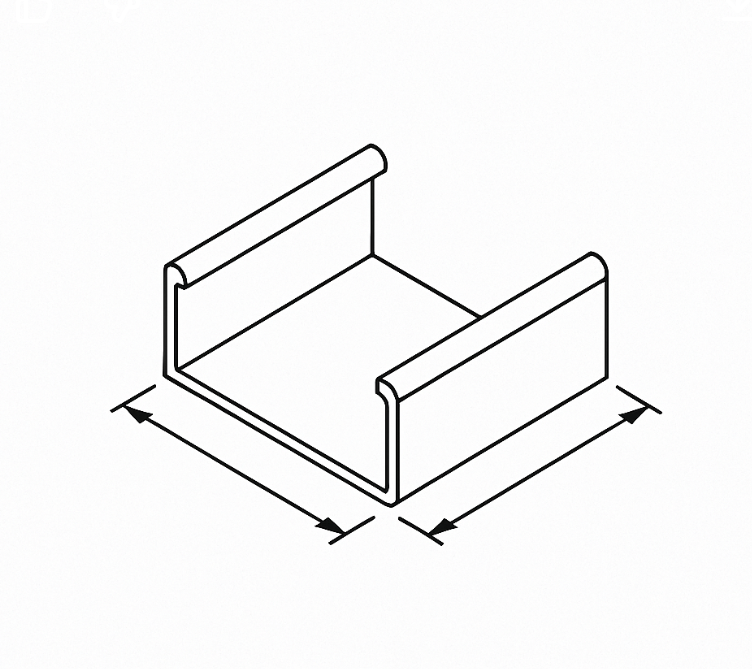

Lipped C-Channel Roll Forming Machine – UAE Supply

Precision Cold-Forming for Structural and Framing Applications

The Lipped C-Channel Roll Forming Machine is a high-precision, heavy-duty forming system engineered for the continuous production of cold-formed C-shaped steel sections with inward-turned edges (lips). Designed to meet the demands of UAE’s fast-paced construction and industrial sectors, this machine supports high-speed production with exceptional profile accuracy, stability, and repeatability.

Whether you're manufacturing steel framing systems, purlins, cable tray supports, rack components, or structural building sections, this roll forming machine delivers quality at scale. It's optimized for the United Arab Emirates market, ensuring compatibility with local power standards, materials, and industrial usage requirements.

Machine Type: Lipped C-Channel Roll Forming Machine (Automatic Line)

Production Speed: 15–25 meters per minute (can vary based on material and profile complexity)

Material Thickness Range: 1.0 – 3.0 mm

Material Width Range: 100 – 600 mm (depends on profile design)

Material Types: Galvanized steel, cold rolled steel, mild steel, stainless steel

Material Yield Strength: Up to 350 MPa (customizable for higher KSI steels)

Roller Material: High-grade GCr15 (chromium steel), heat-treated

Roller Surface Treatment: Hard chrome plating for wear resistance

Number of Forming Stations: 16–24 stations (depending on profile depth and lip design)

Roller Shaft Diameter: 70 mm

Shaft Material: Solid 45# steel, precision ground and hardened

Main Drive Type: Gearbox or chain drive (based on load and customer preference)

Power (UAE compatible): 380V, 50Hz, 3-phase (customizable to local requirements)

Motor Power: 15–22 kW (depends on line speed and profile dimensions)

Cutting Method: Hydraulic shear

Blade Material: Cr12Mov, quenched and tempered for long-lasting sharpness

Control Type: PLC automatic control (typically Siemens, Delta, or Mitsubishi)

Operating Mode: Fully automatic with touch screen HMI

De-coiling System: 3–5 ton manual or hydraulic decoiler (optional motorized decoiler available)

Punching/Notching System (if included): Hydraulic pre-punching station with programmable dies

Machine Frame: Welded H-beam steel, stress-relieved for durability

Thickness of Frame Steel: 18–22 mm base plate

Profile Shape: Lipped C-Channel

Profile Width and Depth: Customizable — typical widths from 80mm–300mm, depths from 40mm–100mm, lips 15–25mm

Length Tolerance: ±1.0 mm

Safety Features:

Protective Covers/Guards

Emergency Stop Button

Overload Protection System

The Lipped C-Channel Roll Forming Machine is ideal for:

Pre-engineered building (PEB) manufacturers

Steel frame system producers

Rack and shelving system manufacturers

Cable tray and support frame fabricators

Solar mounting structure manufacturers

Construction and infrastructure firms

UAE’s demand for pre-fabricated construction, lightweight framing, and modular steel structures makes this machine a valuable asset across Dubai, Abu Dhabi, Sharjah, and other industrial zones.

Prices start from: $65,000 USD (standard configuration)

Final pricing depends on:

Profile dimensions and lip configurations

Thickness and material grade

Optional extras (automatic stackers, notching, coil cars, punching stations, hydraulic decoiler)

Line speed requirements and drive systems

All machines are new and custom-built to meet your specific profile needs. They can be delivered anywhere in the UAE, directly from our trusted manufacturing partners. Support, setup guidance, and one-year warranty coverage are included with every machine.

To ensure we deliver the most accurate quote for your project, please email your profile drawings, material details, and production goals to [email protected]. Our engineering team will respond with tailored options and pricing.

Q: Can this machine produce multiple sizes of C-channels?

A: Yes, the machine can be designed with manual or automatic width/lip adjustment to accommodate multiple sizes.

Q: Is punching included in the machine?

A: Punching and notching can be included as optional hydraulic stations—customized based on your drawing.

Q: What’s the lead time for delivery to the UAE?

A: Standard lead time is 45–75 days depending on complexity and factory schedule. Delivery to UAE ports is arranged by our logistics team.

Q: Do you offer installation and training support in the UAE?

A: Yes. On-site or remote installation support, operator training, and long-term maintenance assistance are all available.

Q: What type of power supply is this machine compatible with?

A: The system is configured for 380V, 50Hz, 3-phase, which is standard in the UAE.

Q: Can the machine be used with high-strength steel (above 350 MPa)?

A: Yes, with proper roller design and upgraded drive systems, we can support steels up to 550 MPa yield strength.

For detailed information, additional drawings, or to start your order, contact the Machine Matcher team today. We are ready to assist customers across the UAE construction and industrial sectors with tailored solutions and full-service support.

Copyright 2026 © Machine Matcher.