To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

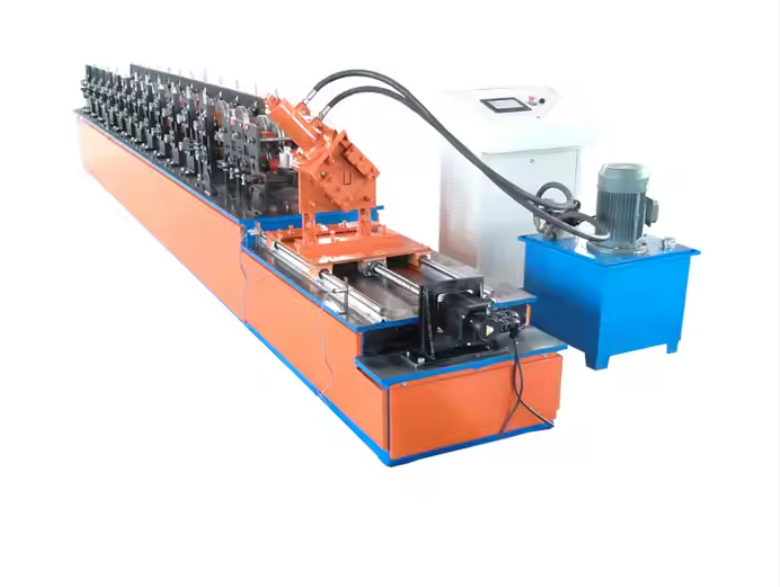

Metal Ceiling Roll Forming Machine – United Arab Emirates

The Metal Ceiling Roll Forming Machine is designed to manufacture high-precision, lightweight ceiling panel profiles used in commercial and residential building interiors. Engineered for continuous production and long-term performance, this machine is ideal for UAE-based construction material suppliers, ceiling system manufacturers, and interior finishing contractors. With growing demand for durable and aesthetic metal ceiling systems across cities like Dubai, Abu Dhabi, and Sharjah, this machine provides a reliable, scalable production solution tailored to local and export markets.

This machine forms suspended metal ceiling profiles—such as C-type carriers, T-bars, or decorative ceiling panels—through a continuous cold roll forming process. It ensures high speed and consistency across each production cycle, enabling users to deliver large-volume orders with tight tolerances. The system is equipped with an integrated PLC control unit, precise hydraulic cutting, and hardened rollers, allowing for customization based on specific profile shapes, gauges, and finishes.

Whether you are producing commercial ceiling grid systems or decorative architectural metal ceiling strips, this roll forming line is built to deliver quality output with minimal operator supervision.

Machine Type: Metal Ceiling Profile Roll Forming Machine

Production Speed: 20–30 meters per minute

Material Thickness Range: 0.3 – 0.7 mm

Material Width Range: 100 – 400 mm (adjustable based on profile)

Material Types: Galvanized Steel, Aluminum, Pre-painted Steel

Material Yield Strength: Up to 280 MPa

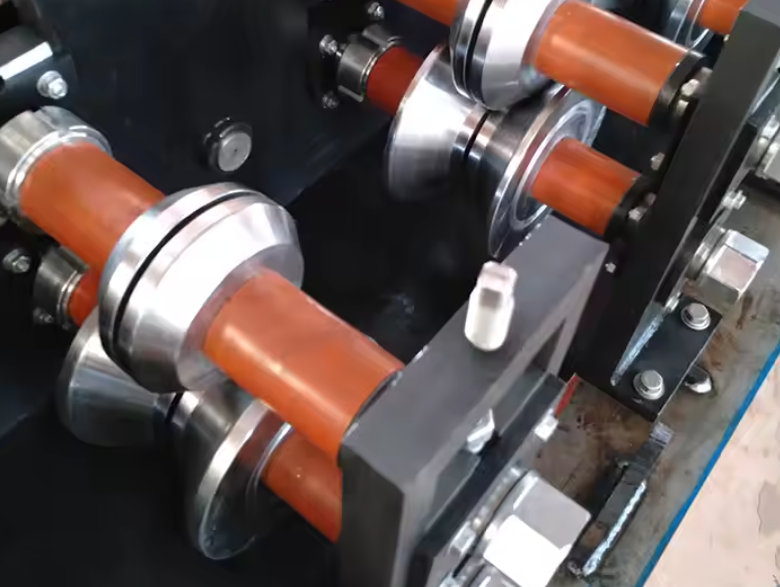

Roller Material: GCr15 (hardened chrome-plated steel)

Roller Surface Treatment: Heat-treated, Hard Chrome Coating

Number of Forming Stations: 10–18 stations (depends on profile)

Roller Shaft Diameter: 40–60 mm

Shaft Material: Solid 45# steel, precision-machined

Main Drive Type: Chain Drive / Gearbox (optional upgrade)

Power for UAE: 380V / 50Hz / 3 Phase

Motor Power: 5.5 – 7.5 kW

Cutting Method: Hydraulic Cutting System

Blade Material: Cr12Mov (heat treated, long service life)

Control Type: PLC with touchscreen HMI (Siemens or Delta)

Operating Mode: Fully automatic with manual override

De-coiling System: Manual or Hydraulic Decoiler (3–5 tons optional)

Punching/Notching System: Optional hydraulic punching station

Machine Frame: Welded structural steel base, stress-relieved

Thickness of Frame Steel: 16–20 mm

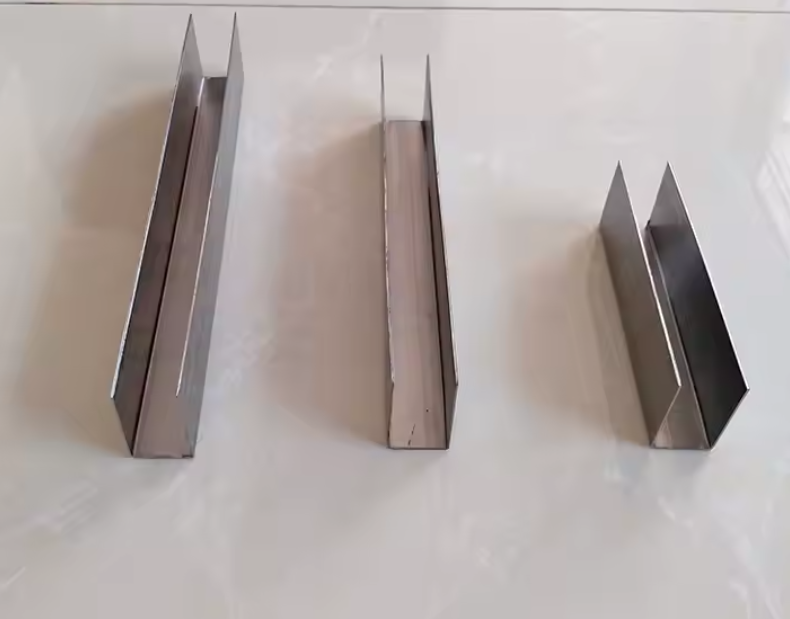

Profile Shape: Custom profile (based on customer drawing)

Profile Width and Depth: Varies per ceiling system (typically 25–80 mm height)

Length Tolerance: ±1.0 mm per 6 meters

Protective Covers/Guards on all moving parts

Emergency Stop Button on Control Panel

Overload Protection System for Motor and Hydraulics

$36,000 USD depending on configuration, motor brand, punching/notching stations, and extras.

Custom profile tooling design

Number of forming stations

Type and capacity of decoiler

Punching or notching station requirements

Choice of automation (basic or advanced PLC)

Brand and country of electrical components

Material thickness/gauge range and production speed

Contact us to receive a custom quote tailored to your profile requirements and production goals.

All machines are new and custom-built based on your requested profile dimensions and output requirements. Machines can be shipped anywhere in the UAE, including Dubai, Abu Dhabi, Sharjah, Ajman, and other Emirates.

Warranty: 1 Year from date of dispatch

Support: Durable after-sales service, remote troubleshooting, and spare parts availability

Shipping: EXW, FOB, or CIF terms available on request

Interior Design and Fit-Out Companies

Ceiling Grid Manufacturers

Construction & Building Materials Suppliers

Commercial Office and Shopping Mall Projects

Modular Building Manufacturers

To ensure we offer the best price and configuration, please send the following information to:

Profile drawing or sketch

Desired width, height, and gauge

Power supply at your factory

Required production speed

Delivery location and timeline

Q1: Can the machine make different ceiling profiles?

Yes, it can be customized with interchangeable tooling or built for a specific profile depending on your needs.

Q2: Is this machine suitable for lightweight aluminum ceiling strips?

Absolutely. It supports galvanized steel, aluminum, and color-coated coil up to 0.7 mm thickness.

Q3: Can you include a punching unit for lighting slots or holes?

Yes, optional hydraulic or servo punching systems can be added before the forming stations.

Q4: How long is the lead time?

Typical production time is 45–60 days after deposit confirmation, depending on configuration.

Q5: Do you offer installation support in the UAE?

Yes, we can arrange remote setup support or send technicians to assist on-site.

For professional-grade ceiling profile production with high reliability, Machine Matcher offers tailor-made roll forming machines that match your production scale and budget.

Let’s build your perfect ceiling system line—Email us today at [email protected] to get started.

Copyright 2026 © Machine Matcher.