To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

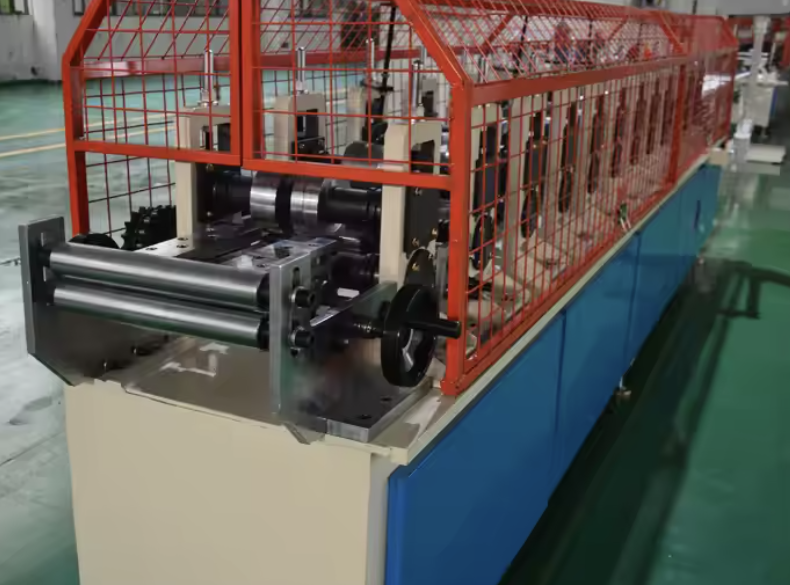

Metal Ceiling Support Roll Forming Machine – United Arab Emirates

The Metal Ceiling Support Roll Forming Machine is a high-precision, fully automated system designed for producing metal ceiling support structures, specifically for the construction and interior finishing industries. Engineered with cutting-edge technology, this machine is ideal for manufacturing C U stud track profiles used in ceiling support frameworks. The machine offers superior accuracy, consistency, and efficiency, making it an essential addition for metal fabricators, contractors, and industrial suppliers in the United Arab Emirates (UAE).

Designed for durability and reliability, this roll forming machine is custom-built to meet customer-specific profile and machine requirements. It can process galvanized coils with a thickness range of 0.4-1.2mm and ensures a rolling speed of 8-15 meters per minute. The system is controlled via a PLC system, ensuring precision in operation. The high-grade materials used in the rollers and cutting components contribute to long-lasting performance and reduced maintenance costs.

This machine will be shipped directly to the customer's location from our manufacturing partner and includes full support for setup, maintenance, and customization.

The Metal Ceiling Support Roll Forming Machine is widely used in:

All machines are new and custom-built based on customer specifications. We provide full customization options, including optional extras such as embossing features, additional cutting mechanisms, and enhanced automation settings. Pricing is determined based on the selected features and customer requirements.

This machine is shipped directly from our manufacturing partner to the customer's location in the UAE. We offer complete assistance with machine setup, training, and technical support to ensure seamless integration into your production line.

Machine Matcher supplies a wide range of roll forming machines to customers worldwide, including:

In addition to sales, Machine Matcher provides full support services, including machine maintenance, repair, setup, and adjustment, ensuring optimal performance for roll forming operations.

If you have profile drawings or any specifications that can help us provide the best quote for this machine, please email your details to [email protected].

Q1: What industries benefit from using the Metal Ceiling Support Roll Forming Machine? A: This machine is widely used in the construction, interior design, metal fabrication, and infrastructure industries for producing ceiling support frameworks and structural components.

Q2: What materials can this machine process? A: The machine processes galvanized coils with thicknesses ranging from 0.4mm to 1.2mm.

Q3: Can the machine be customized? A: Yes, the machine is fully customizable based on specific profile requirements, additional cutting or embossing features, and automation settings.

Q4: What warranty is provided? A: The machine comes with a 2-year warranty covering manufacturing defects and essential maintenance support.

Q5: How is the machine controlled? A: It operates using a PLC (Programmable Logic Controller) system, ensuring precise and automated control for high-accuracy production.

Q6: How is shipping handled for UAE customers? A: The machine is shipped directly from our manufacturing partner to the customer's specified location in the UAE, with full support for setup and installation.

Q7: What is the price of the machine? A: Pricing depends on customization, optional extras, and specific customer requirements. Please contact us for a tailored quote.

Q8: How can I get a quote for this machine? A: Send your profile drawings and any specific machine requirements to [email protected] for a detailed quote.

For more information on roll forming machines and custom solutions, visit Machine Matcher – your trusted supplier of high-quality roll forming equipment worldwide.

Copyright 2026 © Machine Matcher.