To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

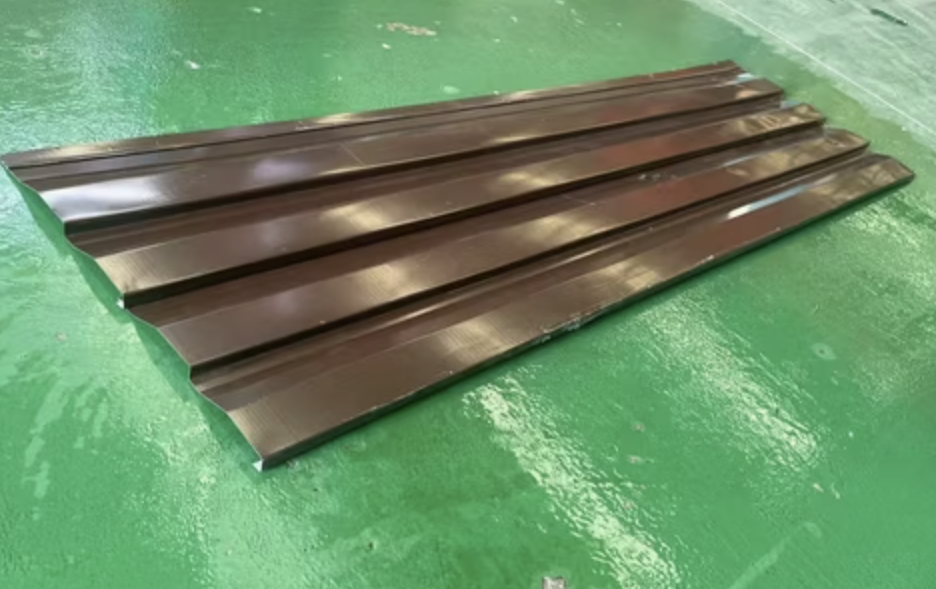

Metal Cladding Roll Forming Machine - United Arab Emirates

The Metal Cladding Roll Forming Machine is a high-performance, precision-engineered machine designed for the UAE’s construction and manufacturing industry. It efficiently produces metal cladding profiles using PPGI, GI, and Aluminum coils, catering to various architectural, industrial, and commercial applications.

With advanced roll forming technology and premium Siemens motors, this machine ensures superior durability, precision, and productivity. It is designed for high-speed, continuous production while maintaining consistency in profile accuracy. The machine can be customized to meet specific customer requirements, ensuring optimal performance based on the desired profile and material specifications.

This Metal Cladding Roll Forming Machine serves multiple industries, including:

Each Metal Cladding Roll Forming Machine is custom-built based on the customer’s specific profile and material requirements. It will be shipped directly to the customer's location in the UAE from our manufacturing partner. The pricing depends on additional customization and optional extras. For a tailored quote, contact us with your specific needs.

Machine Matcher supplies a variety of roll forming machines, including:

For the best quote, send profile drawings or specifications to: [email protected]

Machine Matcher serves industries across Europe, the Middle East, North and South America, Africa, and Asia.

Q1: What materials can the Metal Cladding Roll Forming Machine process? A1: This machine can process PPGI, GI, and Aluminum materials with a width of 315mm and a thickness range of 0.3-0.7mm (customizable).

Q2: Can the machine be customized for specific profiles? A2: Yes, the machine is custom-built to match the customer’s specific cladding profile requirements.

Q3: What is the power requirement for this machine? A3: The standard power requirement is 380V, 50Hz, 3 Phase, but it can be customized if needed.

Q4: How long does delivery take to the UAE? A4: Delivery times vary based on customization but generally take 6-12 weeks, including manufacturing and shipping.

Q5: Does the machine come with a warranty? A5: Yes, all machines come with a 1-year warranty from the date of dispatch, along with durable maintenance and repair support.

Q6: How can I get a quote for this machine? A6: To get a precise quote, please send your profile drawing, material specifications, and additional customization needs to [email protected].

Copyright 2026 © Machine Matcher.