To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Metal Cladding Roll Forming Machine – UAE Market Overview

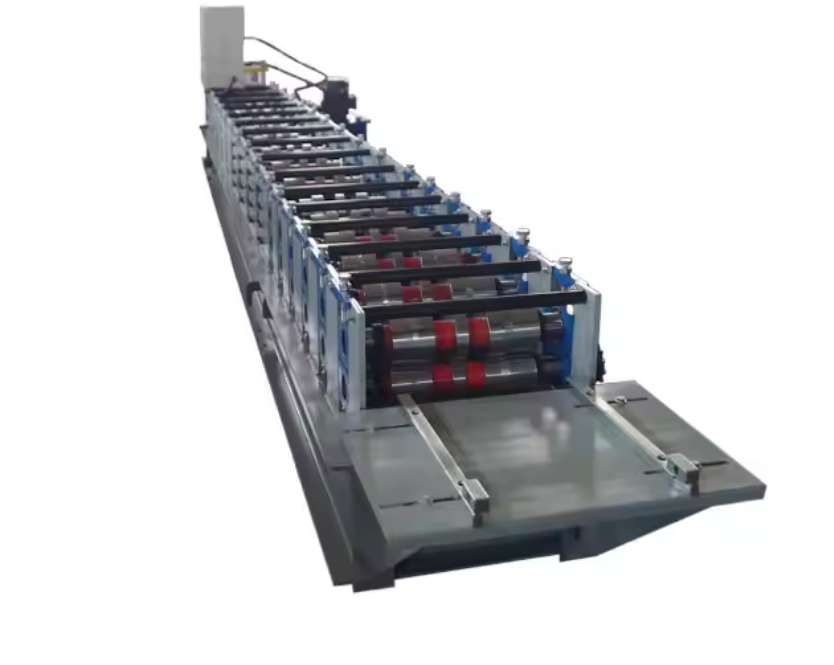

Machine Matcher proudly offers high-performance Metal Cladding Roll Forming Machines, specifically engineered to meet the demands of the United Arab Emirates market. Designed for precision, durability, and efficiency, these machines are capable of forming a wide range of metal cladding profiles used in roofing, siding, and industrial wall systems.

These machines are new, custom-built to meet your exact profile requirements, and can be delivered anywhere in the UAE including Abu Dhabi, Dubai, Sharjah, and all other emirates. Whether you need production at scale or high customization, Machine Matcher provides unmatched solutions tailored for your business.

Machine Type: Metal Cladding Roll Forming Machine

Production Speed: 10–20 meters per minute (based on material type and profile)

Material Thickness Range: 0.3 mm – 1.2 mm

Material Width Range: 600 mm – 1250 mm

Material Types: Galvanized steel, Aluminum, Pre-painted steel, Aluzinc

Material Yield Strength: Up to 550 MPa (80 ksi)

Roller Material: High-grade steel, quenched and tempered

Roller Surface Treatment: Hard chrome coating for wear resistance

Number of Forming Stations: 12 to 20 (depending on profile complexity)

Roller Shaft Diameter: 70 mm

Shaft Material: Solid 45# steel, precision-machined and tempered

Main Drive Type: Chain or gear-driven (based on requirements)

Power (UAE Spec): 380V / 50Hz / 3 Phase

Motor Power: 7.5–11 kW (based on production speed and material gauge)

Cutting Method: Hydraulic post-cutting system

Blade Material: Cr12MoV, heat-treated and ground

Control Type: PLC control with touchscreen HMI

Operating Mode: Fully automatic / manual mode toggle

De-coiling System: Manual or hydraulic de-coiler (3–5 ton capacity)

Punching/Notching System: Optional, integrated into production line

Machine Frame: Welded steel frame, stress-relieved and painted

Thickness of Frame Steel: 18–20 mm

Profile Shape: Customizable

Q: Can the machine be customized for our profile?

A: Yes, all machines are customized based on your supplied profile drawing.

Profile Width and Depth: As per client’s specification

Length Tolerance: ±1.5 mm per 6 meters

Safety Features:

Protective Covers/Guards over moving parts

Emergency Stop Button

Overload Protection System

Remote Installation Support: Yes – remote video guidance available. On-site installation available on request.

Warranty: One-year warranty from dispatch

Maintenance: Durable support with spare parts and repair guidance

Q: What is the lead time for manufacturing and shipping?

A: Manufacturing takes approximately 30–60 days. Shipping time depends on your UAE port location.

This machine is widely utilized in the following industries:

Construction & Infrastructure: Production of cladding panels for residential, commercial, and industrial buildings.

Energy & Utilities: Cladding for power stations, substations, and oil and gas facilities.

Warehousing & Logistics: Creation of metal walls and roofing systems for distribution centers.

Agriculture: Protective enclosures and sheds for farms and agricultural operations.

Examples of Utilization:

Fabricating high-strength exterior wall panels for Dubai skyscrapers

Producing insulated wall sheets for warehouses in Abu Dhabi

Creating aluminum cladding profiles for solar panel housing in Sharjah

Material Types Used: Galvanized steel, PPGI, aluminum

Material Gauge Range: 26 – 18 gauge (0.3 mm – 1.2 mm)

Material Strength: Typically 250 – 550 MPa (36 – 80 ksi)

Prices Start From: Approx. $38,000 USD depending on configuration

What Affects the Final Price:

Profile complexity

Optional systems (de-coiler, punching, notching, etc.)

Production speed

Automation level

Motor and hydraulic component brands

Contact Machine Matcher for a tailored quote. If you have profile drawings or specifications, please email them to [email protected] for accurate pricing.

100% Custom-Built Machines: Every machine is engineered to suit your unique profile and material.

Superior Output Accuracy: With advanced PLC controls and precision cutting, production output is consistently within ±1.5 mm tolerance.

Robust Construction: Built with a heavy-duty frame, hardened shafts, and coated rollers for long operational life under harsh conditions.

Energy Efficiency: Designed for reduced energy consumption without sacrificing performance.

Fast ROI: High-speed production and minimal downtime lead to faster returns on your investment.

Remote & On-Site Support: Whether you need remote troubleshooting or physical installation, we support you in the UAE.

Profile geometry based on drawing

Material handling systems (auto stackers, conveyors)

PLC brand options (Siemens, Delta, Mitsubishi)

Manual or hydraulic decoilers

In-line punching or notching for fastener holes or ventilation slots

Color touchscreen interfaces with multi-language options

Optional hydraulic oil cooling systems for UAE climate

All machines are supplied exclusively by Machine Matcher, with full support from our engineering and logistics teams in the UK and USA. We ensure smooth delivery and commissioning of your machine directly to any location across the United Arab Emirates.

For inquiries, custom designs, or to get a tailored quote, send your profile drawings or specs to:

[email protected]

(Please include machine type, material type, gauge, profile shape, and production goals.)

All machines are new and built-to-order, backed by expert support and comprehensive warranty from Machine Matcher.

Copyright 2026 © Machine Matcher.