To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

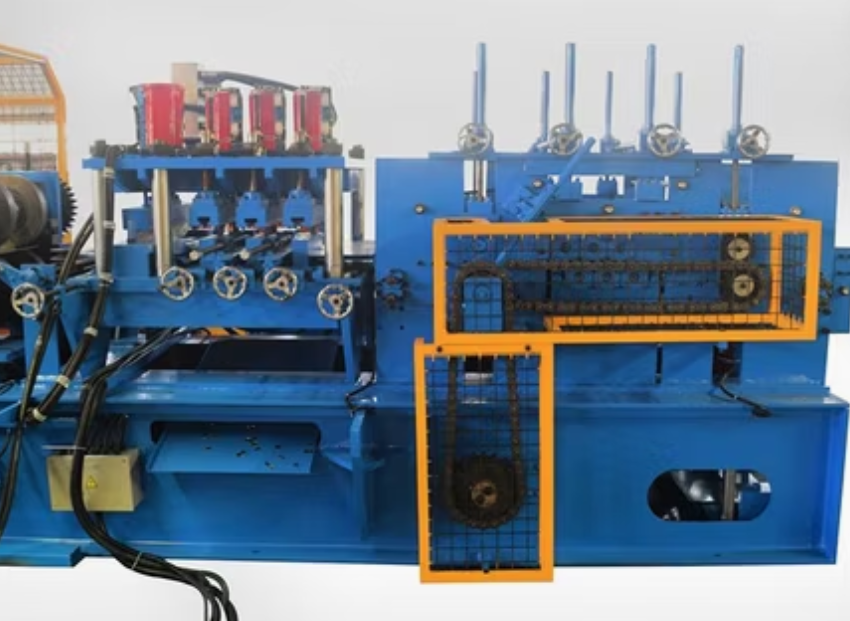

Metal Purlin Roll Forming Machine – United Arab Emirates

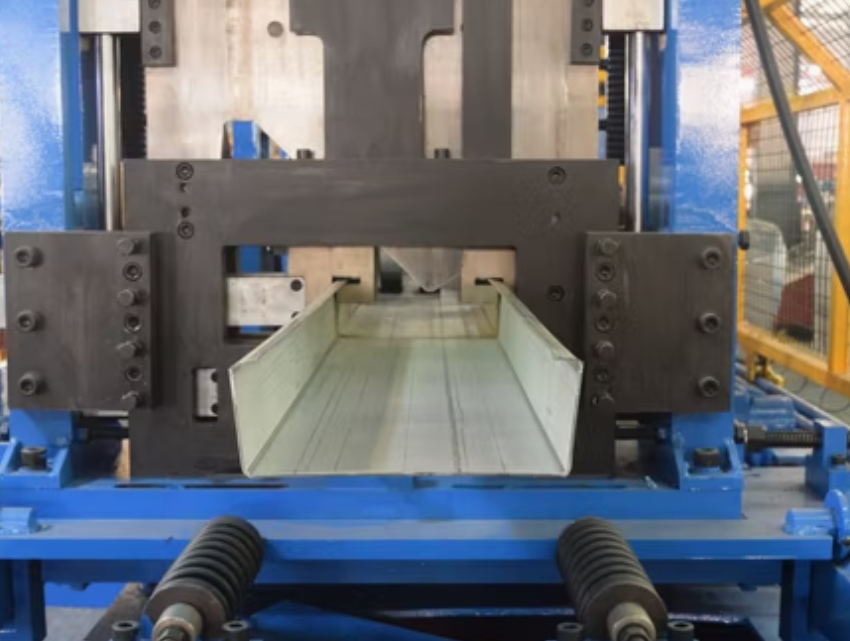

The Metal Purlin Roll Forming Machine is an advanced, precision-engineered solution designed to produce high-quality structural purlins used in commercial, industrial, and residential steel buildings. This machine is ideally suited for companies across the UAE — including in Abu Dhabi, Dubai, and Sharjah — that require dependable and efficient steel profile manufacturing for their construction projects.

Built for versatility and speed, this machine accommodates a wide range of material specifications and profile types, including C, Z, U, Sigma, and Hat-shaped purlins. It supports quick profile changeovers, either semi-automatic or fully automatic (depending on the configuration), making it ideal for operations with diverse project demands and short production timelines.

Whether you're supplying steel buildings, prefabricated warehouses, or solar mounting systems, this machine delivers exceptional strength, accuracy, and consistency — all backed by full technical support and a one-year warranty.

Machine Type: Metal Purlin Roll Forming Machine (for C/Z/U/Sigma profiles)

Production Speed: 10–20 meters per minute (depending on punching and cutting configuration)

Material Thickness Range: 1.2 mm – 3.2 mm

Material Width Range: 100 mm – 500 mm (customizable depending on profile)

Material Types: Galvanized steel, hot-rolled steel, cold-rolled steel, high-tensile steel

Material Yield Strength: Up to 550 MPa

Roller Material: GCr15 bearing steel

Roller Surface Treatment: Heat-treated and hard chrome-coated for wear resistance

Number of Forming Stations: 16–22 (depending on profile complexity)

Roller Shaft Diameter: 70 mm

Shaft Material: High-grade 45# steel, precision-machined

Main Drive Type: Chain drive or gear drive (based on configuration)

Power (UAE-Compatible): 380V / 50Hz / 3 Phase

Motor Power: 15–30 kW depending on design and profile range

Cutting Method: Hydraulic post-cut or flying shear

Blade Material: Cr12MoV, heat-treated

Control Type: PLC control system with touch screen interface (Siemens or Delta)

Operating Mode: Fully automatic or semi-automatic

De-coiling System: Manual or hydraulic uncoiler (3–10 ton capacity)

Punching/Notching System (if included): Hydraulic punching for web, flange, and hole patterns

Machine Frame: Welded steel base frame with integrated leveling system

Thickness of Frame Steel: 20–25 mm

Profile Shape: C, Z, U, Sigma (interchangeable tooling or adjustable by motor)

Profile Width and Depth: Customizable (e.g., 80–300 mm width, 40–100 mm flange)

Length Tolerance: ±1.5 mm per 6 meters

Safety Features:

Protective Covers/Guards

Emergency Stop Button

Overload Protection System

This machine serves the construction, steel building, solar infrastructure, transportation, and industrial storage industries. Applications include:

Steel warehouse and shed framing

Commercial steel buildings

PEB structures

Carports and canopies

Solar panel mounting systems

Agricultural sheds and barns

Cold storage and logistic centers

All metal purlin roll forming machines are custom-built to meet the specific profile and gauge requirements of each customer. We deliver anywhere in the UAE, including:

Abu Dhabi

Dubai

Sharjah

Ajman

Ras Al Khaimah

Fujairah

Umm Al Quwain

Machines are manufactured by our global partner network and shipped directly with local voltage, safety standards, and operational support in mind.

Pricing: Varies based on selected profile type, automation level, punching options, uncoiler system, and output speed.

Warranty: 1-year warranty from dispatch, covering mechanical and control components.

Support: Ongoing remote and on-site technical support, spare parts supply, and maintenance plans available.

For a custom quote, please send your profile drawings, thickness, width range, and production requirements to [email protected].

Q1: Can this machine produce both C and Z purlins?

A: Yes, the machine can be designed as a C/Z interchangeable model with automatic profile shifting or manual tool adjustments.

Q2: How long does it take to manufacture and ship the machine to the UAE?

A: Standard production time is 60–75 days depending on configuration. Shipping to the UAE typically adds 3–4 weeks.

Q3: Can I add punching stations for bolt holes and connection slots?

A: Absolutely. Hydraulic punching units can be integrated for flange holes, web slots, and custom punching patterns.

Q4: Is operator training available?

A: Yes. We provide online and on-site training for machine setup, operation, and maintenance.

Q5: What materials are recommended for best performance?

A: High-quality galvanized or hot-rolled steel with yield strength up to 550 MPa is ideal for long-lasting, high-strength purlins.

For more information or to start your project, contact the Machine Matcher team at [email protected]. We are ready to assist you from quote to commissioning with global expertise and local support.

Copyright 2026 © Machine Matcher.