To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

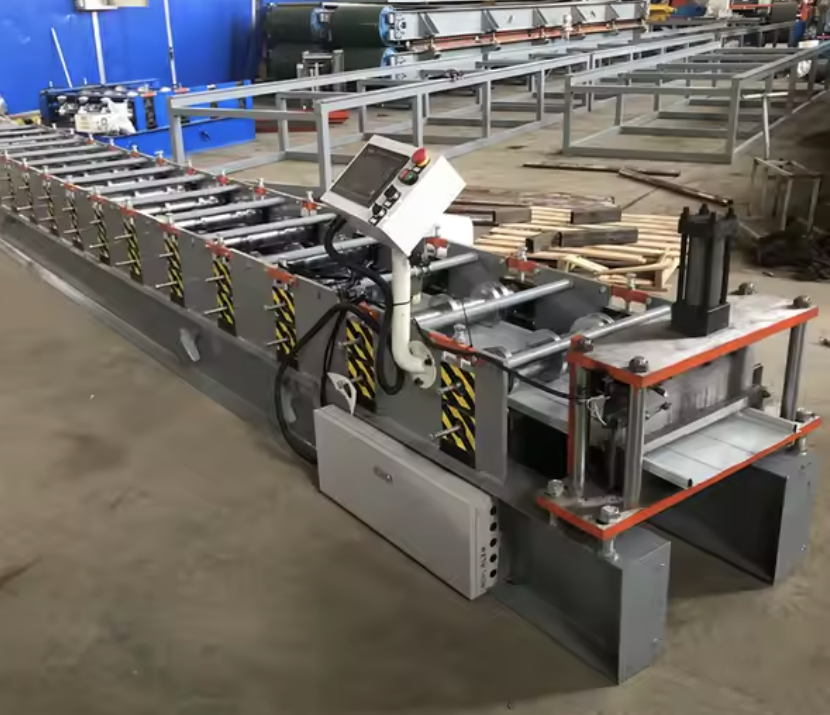

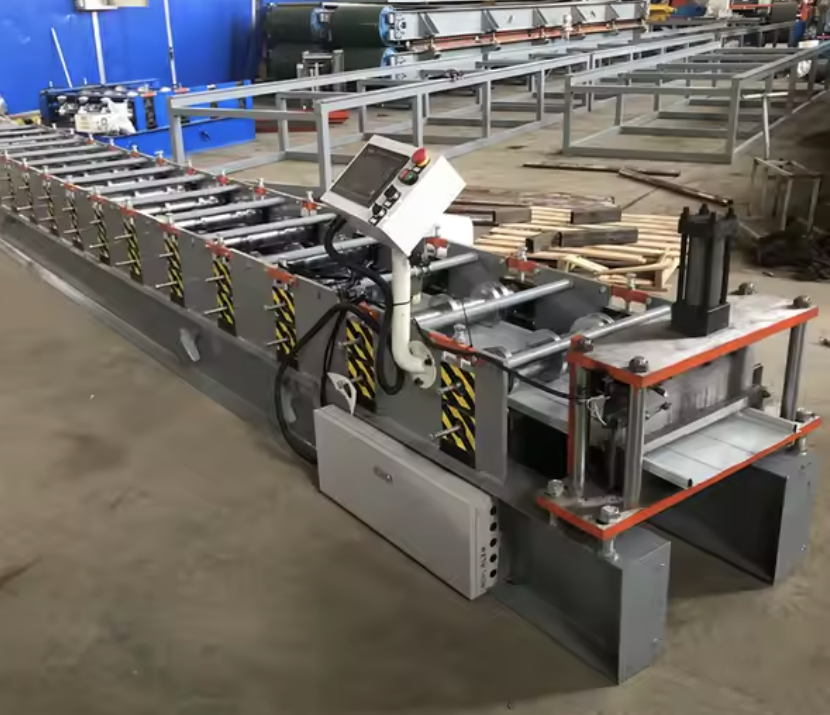

At Machine Matcher, we proudly supply high-quality Metal Roof Cladding Sheet Roll Forming Machines built to deliver exceptional performance for projects across the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah. These machines are new, custom-built to meet your exact profile specifications, and are designed for maximum efficiency, durability, and ease of operation in the demanding building and construction industry.

Whether you’re working on residential, commercial, or industrial buildings, this machine is ideal for producing precise, uniform metal cladding panels used for roofing and wall systems — essential elements for weather protection, thermal insulation, and architectural design.

| Item | Specification |

|---|---|

| Machine Type | Metal Roof Cladding Sheet Roll Forming Machine |

| Production Speed | Up to 15–20 meters per minute |

| Material Thickness Range | 0.3 mm – 0.8 mm |

| Material Width Range | 600 mm – 1250 mm |

| Material Types | Galvanized Steel, Aluminum, Pre-painted Steel, Galvalume |

| Material Yield Strength | Up to 550 MPa |

| Roller Material | High-Grade Steel (Cr12 or GCr15) |

| Roller Surface Treatment | Hard Chrome Coated for corrosion resistance |

| Number of Forming Stations | 16–24 stations (depending on profile) |

| Roller Shaft Diameter | 70 mm |

| Shaft Material | Solid 45# Steel, heat-treated |

| Main Drive Type | Chain Drive or Gearbox Drive |

| Power for UAE | 380V, 50Hz, 3 Phase (customizable) |

| Motor Power | 7.5 kW – 11 kW (depending on requirements) |

| Cutting Method | Hydraulic Cutting (post-cut) |

| Blade Material | Cr12Mov (hardened steel) |

| Control Type | PLC Automatic Control System (brands like Siemens, Delta, or Mitsubishi) |

| Operating Mode | Full Automatic with touch screen HMI |

| De-coiling System | Manual or Hydraulic Decoiler (3–5 Ton) |

| Punching/Notching System | Optional hydraulic punching/notching station available |

| Machine Frame | Heavy-duty welded H-Beam steel frame |

| Thickness of Frame Steel | 18–22 mm |

| Profile Shape | Customizable roof and wall cladding profiles |

| Profile Width and Depth | Based on customer-provided drawings |

| Length Tolerance | ± 2 mm |

| Safety Features | Full suite of protective devices |

| - Protective Covers/Guards | Included around moving parts |

| - Emergency Stop Button | Installed at multiple accessible points |

| - Overload Protection System | Integrated into electrical system |

The Metal Roof Cladding Sheet Roll Forming Machine is extensively used in the building and construction industry across the UAE. These machines manufacture high-quality panels for:

Residential roofing and siding

Commercial and industrial roof and wall cladding

Warehouses and logistics centers

Agricultural storage facilities

Retail centers and malls

Airports, stadiums, and public infrastructure

Because the UAE experiences intense heat, humidity, and occasional sandstorms, the machine is designed to handle high-strength materials that offer long-lasting protection and aesthetic appeal for modern architecture.

Delivery Locations: Abu Dhabi, Dubai, Sharjah, Ajman, Fujairah, Ras Al Khaimah, Umm Al Quwain – and anywhere across the UAE.

Warranty: 1-Year Warranty from dispatch date.

After-Sales Support: Long-term maintenance, repair, and spare parts service available.

Customization: Machines are built to your profile drawings and project specifications.

Contact for Quotes: Email your drawings and requirements to [email protected] for a fast, tailored quotation.

A: Yes, absolutely. We custom-build each machine according to the specific roof and wall cladding profile you need, based on UAE construction standards or your project-specific requirements.

A: The machine can produce panels at speeds of up to 15–20 meters per minute, depending on the material thickness and profile complexity.

A: This machine can process galvanized steel, galvalume, aluminum, and pre-painted steel — all commonly used materials for roofing and cladding panels in the UAE.

A: Thanks to the PLC control system, the machine maintains a ±2 mm length tolerance, ensuring precise panel lengths every cycle.

A: Yes. We offer manual or hydraulic decoilers ranging from 3 to 5 tons capacity, depending on your production needs.

A: Yes, installation guidance, remote support, and operator training are available to customers throughout the UAE.

A: The machine includes full protective guards, emergency stop buttons, and an overload protection system to ensure safe operation at all times.

If you have specific profile drawings, material types, or special features required, please send all relevant details to [email protected]. Our team will review your needs and provide a customized quotation designed to suit your project.

Note: Pricing varies depending on customization options, motor sizes, decoilers, stackers, punching stations, and other features selected.

Would you also like me to prepare a downloadable PDF version of this product description, branded for Machine Matcher? 📄

It could be very useful if you want to send it to potential customers!

Copyright 2026 © Machine Matcher.