To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Metal Roof Purlin Roll Forming Machine – UAE Market Edition

Efficient, Accurate, and Built to Order for Purlin Fabrication in the United Arab Emirates

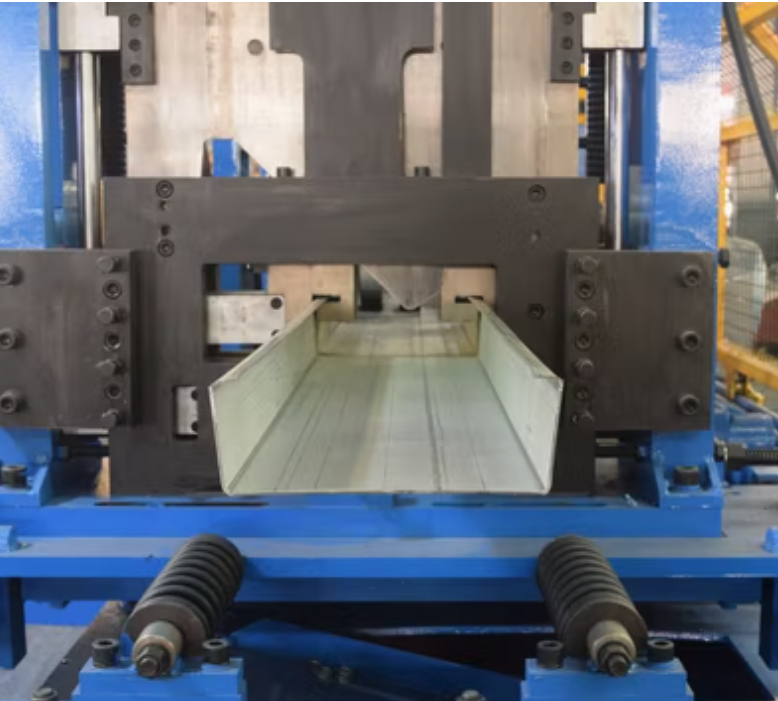

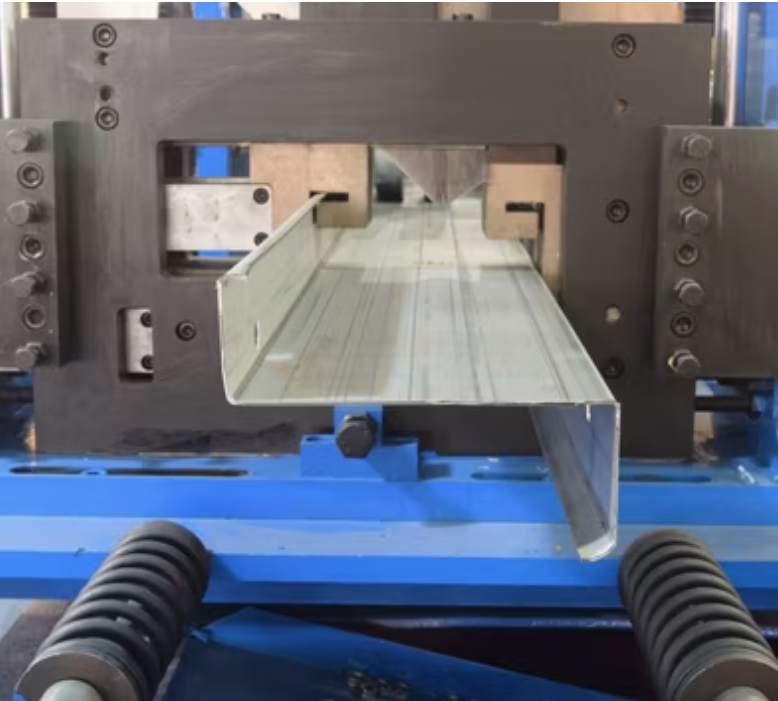

The Metal Roof Purlin Roll Forming Machine is an industrial-grade forming solution designed to produce precision C, Z, or customized roof purlin profiles commonly used in structural roofing systems across the UAE. Built for high-speed production and durability, this machine is suitable for both light and heavy-gauge purlins made from galvanized steel, mild steel, and other coated coil materials.

Engineered for local power standards and regional construction demands in Dubai, Abu Dhabi, Sharjah, and other Emirates, this roll forming system is the preferred choice for purlin manufacturers, steel structure companies, and large-scale building projects throughout the Middle East.

This machine is ideal for the following industries in the UAE:

Pre-engineered building (PEB) manufacturers

Steel structure fabrication

Commercial and industrial roofing projects

Metal building systems

Construction companies

Warehousing and logistic infrastructure developers

With the UAE’s rapid development in industrial zones, logistics hubs, and mega construction projects, roof purlins remain critical structural elements in both temporary and permanent building frameworks.

| Specification | Detail |

|---|---|

| Machine Type: | Metal Roof Purlin Roll Forming Machine |

| Production Speed: | 10–20 meters per minute (adjustable based on profile and punching) |

| Material Thickness Range: | 1.0 – 3.0 mm |

| Material Width Range: | 100 – 600 mm (depending on profile) |

| Material Types: | Galvanized steel, HR/CR steel, pre-painted steel |

| Material Yield Strength: | Up to 350 MPa (optional upgrades for up to 550 MPa) |

| Roller Material: | High-grade GCr15 steel |

| Roller Surface Treatment: | Hard chrome plating for wear resistance |

| Number of Forming Stations: | 16–24 stations depending on profile complexity |

| Roller Shaft Diameter: | 70 mm (customizable) |

| Shaft Material: | High-strength 45# steel, precision-machined |

| Main Drive Type: | Chain drive or gear-driven (customizable) |

| Power (UAE compatible): | 380V, 50Hz, 3-phase |

| Motor Power: | 15 kW (varies based on design and extras) |

| Cutting Method: | Hydraulic cutting system (post-cut or flying cut) |

| Blade Material: | Cr12MoV hardened steel |

| Control Type: | PLC control with touchscreen HMI (Siemens/Delta) |

| Operating Mode: | Fully automatic with manual override |

| De-coiling System: | Manual or hydraulic de-coiler (3–10 tons optional) |

| Punching/Notching System: | Optional servo-punching for holes, slots, or notches |

| Machine Frame: | Welded structural steel base, stress-relieved |

| Thickness of Frame Steel: | 20–25 mm reinforced |

| Profile Shape: | C, Z, Sigma, or customized purlin shapes |

| Profile Width and Depth: | Widths from 100–300 mm; depths up to 80 mm |

| Length Tolerance: | ±1.0 mm |

| Safety Features: | Protective covers, interlocked guards, safety sensors |

| Protective Covers/Guards: | Full-length covers over moving parts |

| Emergency Stop Button: | Multiple emergency stop points along the line |

| Overload Protection System: | Included in the control cabinet with reset function |

All machines are newly manufactured and custom-built to meet each customer’s specific profile and operational requirements. Machines are delivered anywhere in the United Arab Emirates, including:

Dubai

Abu Dhabi

Sharjah

Ajman

Ras Al Khaimah

Fujairah

Umm Al Quwain

Machines are built to match local electrical and industrial standards and come with comprehensive after-sales support, including remote troubleshooting, spare parts supply, and on-site installation support.

Pricing depends on machine configuration, profile complexity, and optional extras (e.g., automatic stackers, servo feeders, hydraulic de-coilers).

💡 Warranty: All machines come with a 1-year warranty from dispatch, and long-term maintenance and repair support is available.

📧 To receive a quote:

Buyers are encouraged to send their profile drawings, material specifications, and production needs to:

📨 [email protected]

Q1: Can this machine produce both C and Z purlins?

Yes. With a quick-change design or fully automatic adjustability, the machine can switch between C and Z profiles with minimal downtime.

Q2: What kind of materials can the machine process?

It can roll form galvanized steel, hot-rolled or cold-rolled steel, and coated steel, up to 3.0 mm in thickness and 350 MPa in strength.

Q3: Is the machine compatible with UAE power standards?

Yes. The electrical system is built for 380V / 50Hz / 3-phase, standard across industrial zones in the UAE.

Q4: Can I add punching for bolt holes?

Yes. An optional servo-driven hydraulic punching system is available, and tooling can be customized to your pattern.

Q5: How long is the lead time?

Typical production and delivery time ranges from 50 to 70 days, depending on machine complexity and order queue.

Q6: Do you offer installation or training in the UAE?

Yes. We offer on-site installation, commissioning, and operator training, as well as remote support.

Q7: Can this machine be upgraded in the future?

Yes. Systems such as auto stackers, flying cut systems, or coil handling automation can be retrofitted later.

The Metal Roof Purlin Roll Forming Machine is a future-ready, high-precision solution tailored for the UAE construction and steel fabrication sector. Built to withstand demanding conditions and deliver consistent results, it is the go-to choice for companies looking to produce quality structural components at scale.

Contact Machine Matcher

Email: [email protected]

All machines are new, custom-built, and delivered across the UAE.

Copyright 2026 © Machine Matcher.