To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

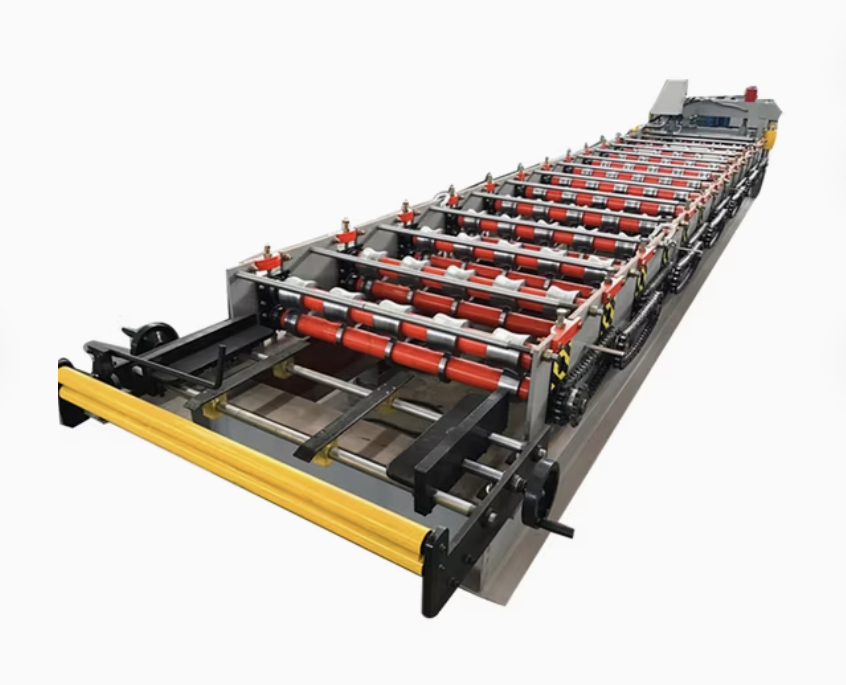

A metal roof roll forming machine is an advanced piece of equipment designed to convert metal coils into roofing panels of various profiles. These machines can produce profiles such as standing seam, corrugated panels, trapezoidal panels, and more, catering to diverse roofing needs in Colombia's construction market.

Key Features:

A: The machine can produce a wide range of profiles, including standing seam panels, trapezoidal sheets, corrugated panels, and more. Custom dies can be added to meet specific profile requirements in Colombia.

A: Yes, it is compatible with galvanized steel, pre-painted steel, aluminum, and zinc alloys, commonly used in Colombia's construction industry.

A: Absolutely. The machine can be configured for 220V or 380V power supply, with 50Hz or 60Hz frequency to match Colombian standards.

A: The machine features a user-friendly PLC system for easy operation and a detailed manual for setup and maintenance. Additionally, remote support and on-site training can be provided.

A: The production speed ranges from 10 to 30 meters per minute, with an average daily output depending on panel length and material.

A: With regular maintenance, the machine can last over 10 years, thanks to its durable construction and high-quality components.

A: Spare parts can be shipped directly to Colombia. Many standard components are available locally, ensuring minimal downtime.

A: Yes, the machine can be tailored to meet specific profile requirements, material thicknesses, and additional features like embossing or perforation.

Investing in a metal roof roll forming machine is a strategic decision for businesses in Colombia's construction industry. The machine's versatility, efficiency, and ability to produce high-quality profiles ensure it meets the growing demand for durable and aesthetic metal roofing solutions in the country. With customization options and robust after-sales support, this machine is an indispensable asset for roofing manufacturers in Colombia.

Copyright 2026 © Machine Matcher.