To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

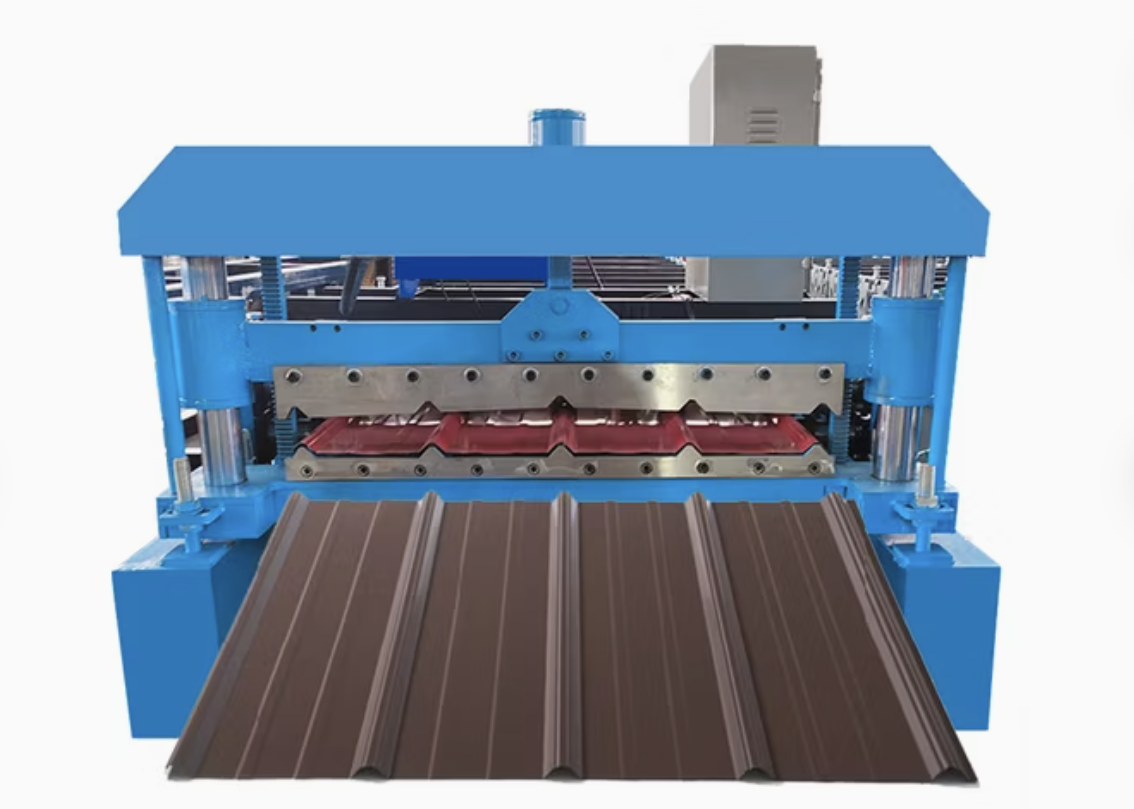

A Metal Roof Roll Forming Machine is a specialized industrial machine designed to fabricate metal roof panels used in various types of roofing applications. These machines are engineered to create consistent, high-quality metal panels by feeding coiled sheet metal through a series of roller stations. As the sheet metal passes through each roller, it is gradually shaped to the desired profile for metal roofing. The process is efficient, reducing material waste and labor costs while allowing for large-scale production.

The machine is widely utilized in construction, commercial roofing, and residential roofing industries due to its ability to produce durable, weather-resistant metal panels. The roll forming process enables customization in terms of profile design, panel length, and material, allowing users to meet diverse project requirements.

The machine setup requires a dedicated installation area, power supply, and skilled operators familiar with roll forming machines. Calibration of roller alignment and hydraulic systems is essential for precise operation.

Q: What materials can be used with a Metal Roof Roll Forming Machine?

A: The machine can handle various materials including galvanized steel, aluminum, and steel. The material choice depends on the roofing application and environmental conditions.

Q: What is the maximum speed of a Metal Roof Roll Forming Machine?

A: The speed typically ranges between 10-20 meters per minute, but high-end models may achieve faster production speeds depending on the complexity of the profile and material thickness.

Q: How does the PLC control system improve production efficiency?

A: The PLC system allows operators to input precise measurements and customize profiles, ensuring consistency and reducing errors. The touchscreen interface simplifies adjustments, and remote control options enable better monitoring.

Q: Can the machine be customized for specific roof panel profiles?

A: Yes, the machine is highly customizable, allowing different roller configurations to produce unique profiles suitable for specific roofing designs.

Q: What are the safety features of this machine?

A: Safety features typically include protective guards around moving parts, emergency stop buttons, and control enclosures to minimize the risk of accidents during operation.

Q: How long does it take to install a Metal Roof Roll Forming Machine?

A: Installation time varies depending on machine size and site conditions, but generally, it requires a few days for setup, calibration, and testing before full operation.

Q: What maintenance is required to keep the machine running efficiently?

A: Routine maintenance includes lubrication, inspection of moving parts, replacement of worn components, and ensuring the hydraulic and drive systems are functioning optimally.

Q: Is it possible to use the machine for different roofing panel lengths?

A: Yes, the length can be easily adjusted via the control system to produce panels of various lengths as per project requirements.

Copyright 2025 © Machine Matcher.