To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

A Metal Roof Tile Roll Forming Machine is a specialized piece of equipment designed to produce metal roof tiles in various shapes and profiles. These machines are engineered to create metal roof tiles from materials such as galvanized steel, aluminum, and copper, providing durable, weather-resistant roofing solutions for commercial, industrial, and residential buildings. With high-speed production capabilities, these machines allow for the efficient and cost-effective manufacturing of metal tiles that offer both strength and aesthetic appeal.

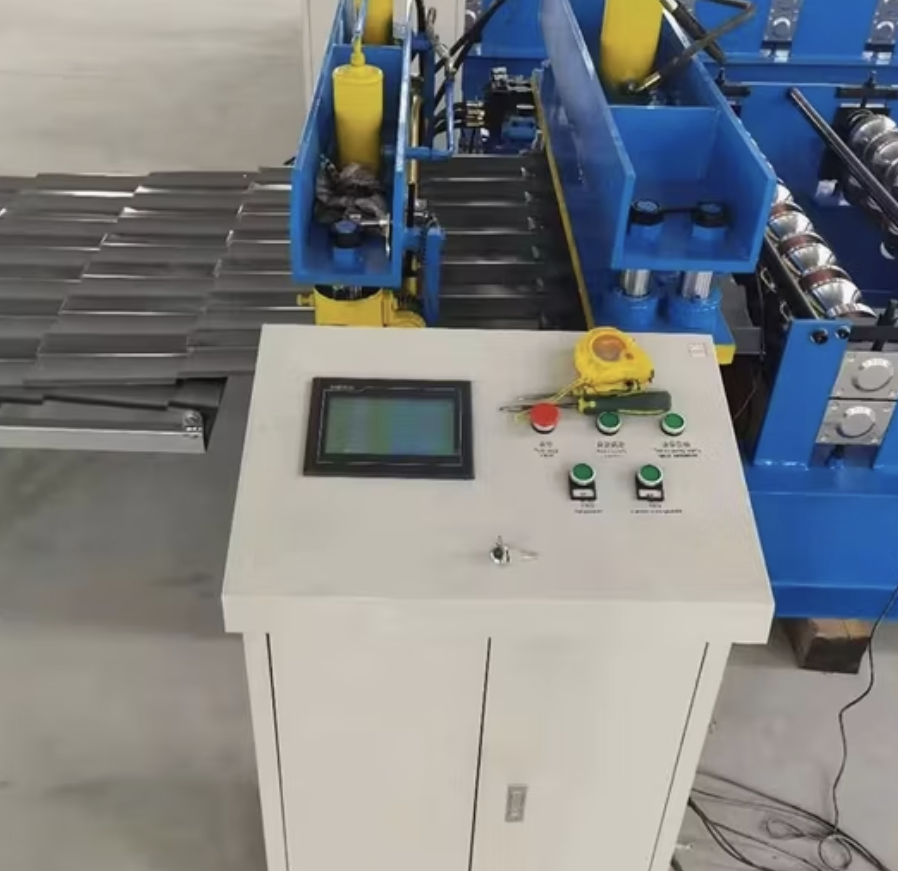

The Metal Roof Tile Roll Forming Machine typically includes a decoiler, roll forming system, hydraulic cutting system, and PLC control system. The machine feeds metal sheets through a set of precisely engineered rollers that progressively shape the sheets into the desired profile. The hydraulic cutter trims each tile to a specific length, ensuring uniformity. The PLC control system offers precision in operation, automating the production process and enabling high-quality, consistent output.

The Metal Roof Tile Roll Forming Machine typically requires a solid foundation for vibration control and stability. Professional installation is recommended to ensure alignment and correct setup. Technicians usually configure the PLC system according to the customer’s desired tile specifications and provide training on operation and maintenance.

A: This machine is compatible with materials like galvanized steel, aluminum, and copper, with thicknesses ranging from 0.3 mm to 0.6 mm.

A: Depending on the model, the machine can be adjusted to produce various profiles, including popular styles like Spanish, Roman, and shingle tiles. Custom profiles may also be possible with specific roller designs.

A: The machine typically operates at 8-15 meters per minute. Production speed can vary based on the material thickness and profile complexity.

A: The setup time may take a few hours to a full day, depending on the complexity of the installation and customization requirements.

A: Yes, most suppliers offer training for machine operation, PLC system usage, and basic maintenance.

A: Regular lubrication, roller cleaning, hydraulic system checks, and PLC maintenance are essential. Routine inspections can help prolong the life of the machine and maintain high production quality.

A: Yes, most manufacturers offer customization options such as additional embossing rollers, specialized cutting systems, or automated stacking.

A: Common issues include roller misalignment and hydraulic system wear. These can often be resolved through regular inspections, prompt maintenance, and ensuring that operators are well-trained in machine operation.

Copyright 2026 © Machine Matcher.