To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

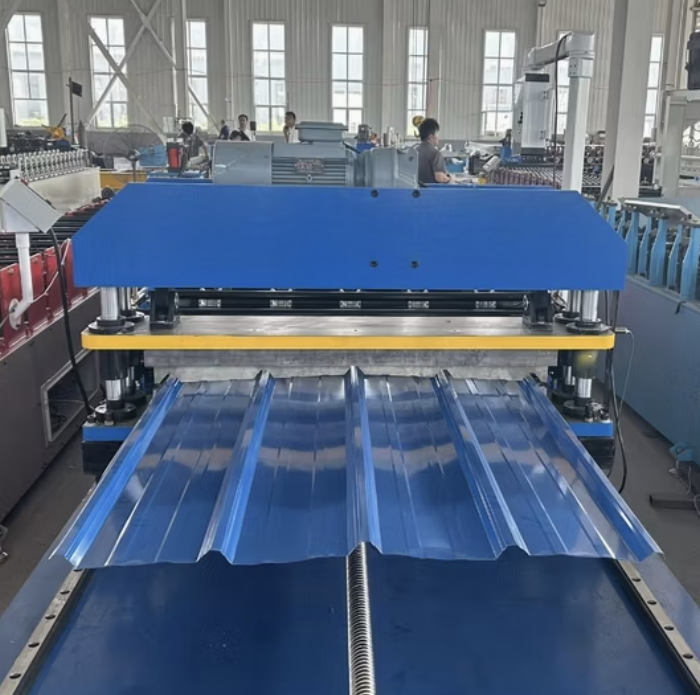

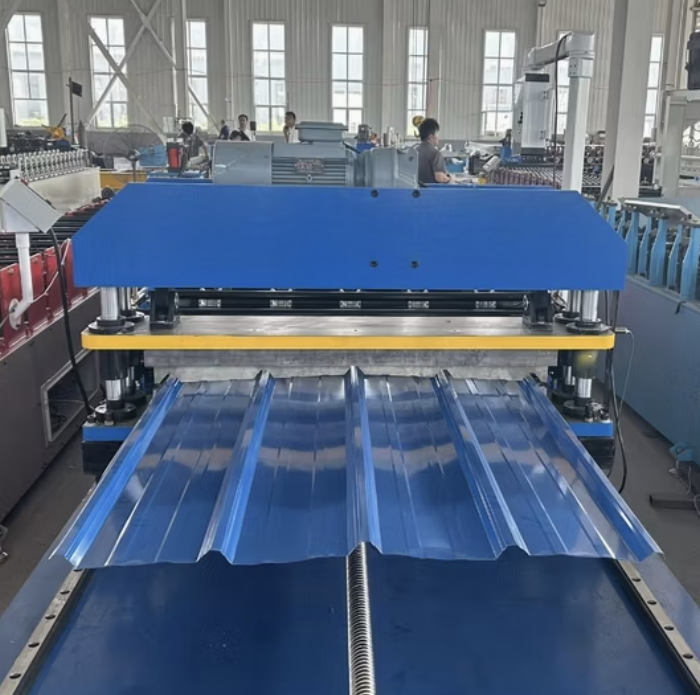

Albania, with its rapidly growing construction industry, has seen an increasing demand for durable and efficient roofing solutions. Metal roofing has become a popular choice due to its longevity, energy efficiency, and ability to withstand harsh weather conditions. The Metal Roofing Roll Forming Machine is designed to cater to this demand by producing high-quality metal roofing panels efficiently and consistently.

This machine is engineered to deliver precision and efficiency, making it a preferred choice for construction companies, roofing contractors, and manufacturing businesses in Albania. Whether for residential, commercial, or industrial projects, this roll forming machine is designed to handle a variety of roofing profiles to suit diverse requirements.

The Metal Roofing Roll Forming Machine features a robust 350H steel frame, ensuring durability and stability during high-speed operations. The sturdy construction minimizes vibrations, thereby enhancing the precision of the formed profiles.

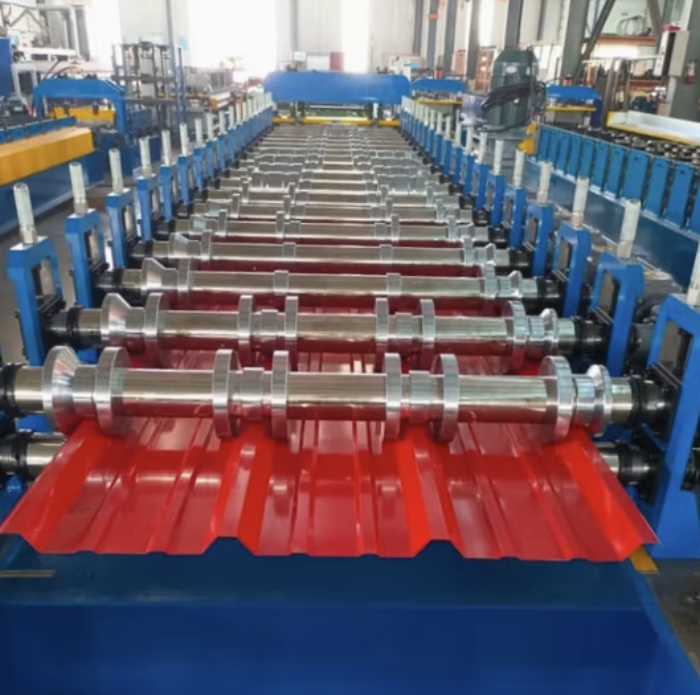

Manufactured from 45# steel and processed with CNC lathes, the rollers are hard chrome coated to prevent corrosion and ensure a longer lifespan. This coating also aids in smooth profile forming, minimizing surface imperfections on the finished product.

With a 70mm shaft diameter and a 16mm thick middle plate, the machine is capable of maintaining accurate alignment of rollers, ensuring consistent profile dimensions across long production runs.

Powered by a 4KW main motor, the machine can efficiently produce roofing panels at a speed of 13-15 meters per minute, making it suitable for both medium and large-scale production demands.

The machine operates on a standard 380V/50HZ/3PH electrical configuration, commonly used in Albania. However, customization options are available to suit different regional requirements.

These profiles are widely used in Albania for residential, commercial, and agricultural buildings due to their durability and weather resistance.

With a material thickness range of 0.3-0.8mm, this machine is versatile enough to handle a wide variety of metal types used in the Albanian construction industry.

Pricing is determined based on optional extras and customization requirements. Contact us for a tailored quote based on your specific needs.

Q1: What types of metal roofing profiles can this machine produce?

A: The machine is capable of producing trapezoidal, corrugated, and standing seam roofing sheets, which are popular in Albania's construction industry.

Q2: Is the machine compatible with different power standards?

A: Yes, the electrical configuration can be customized according to local power standards.

Q3: What is the maximum material thickness the machine can handle?

A: The machine is designed to handle metal sheets with a thickness range of 0.3-0.8mm.

Q4: Can this machine be used for aluminum and copper sheets?

A: Yes, it is compatible with galvanized steel, color-coated steel, aluminum, and copper.

Q5: What is the delivery time for this machine in Albania?

A: Typically, delivery takes 30-45 days, depending on customization requirements.

Q6: How can I get a quote for this machine?

A: You can contact us directly with your specific requirements for a tailored quote.

Q7: Is training provided for machine operation?

A: Yes, we offer both on-site and remote training options.

The Metal Roofing Roll Forming Machine is an excellent investment for businesses in Albania seeking to enhance their roofing panel production capabilities. Its durability, efficiency, and customizable options make it a versatile solution for various industries. For pricing and more details, contact us with your requirements.

Copyright 2026 © Machine Matcher.