To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

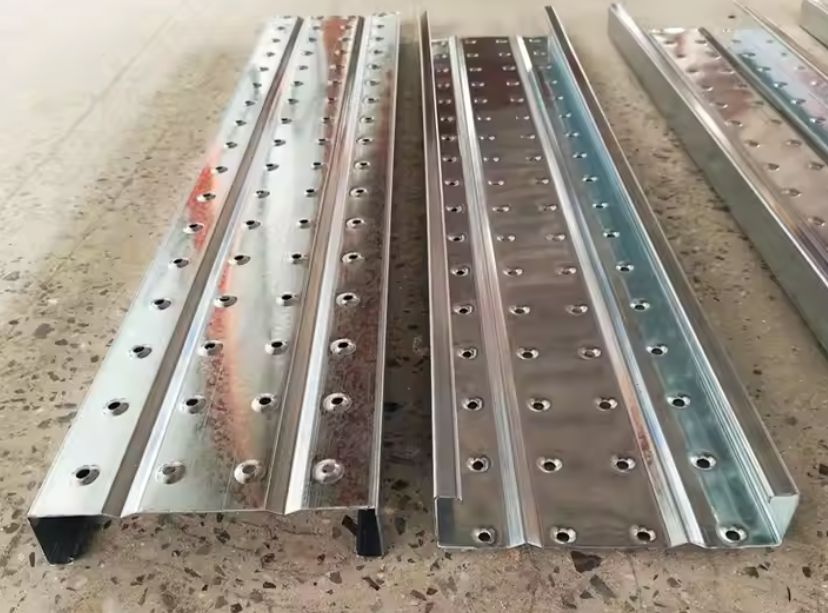

Metal Scaffolding Planks Board Roll Forming Machine – (UAE)

Machine Matcher is proud to offer the Metal Scaffolding Planks Board Roll Forming Machine to customers throughout the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah. Designed and engineered for precision, durability, and high-volume output, this machine is ideal for producing heavy-duty scaffolding planks that meet safety and structural standards across various industries.

This roll forming system is a powerful, fully automated production line tailored to fabricate steel scaffolding boards with consistent width, depth, and structural integrity. All machines are custom-built to your profile requirements, delivering excellent performance, long-term reliability, and low maintenance operation.

Machine Type: Metal Scaffolding Planks Board Roll Forming Machine

Production Speed: 10–15 meters per minute

Material Thickness Range: 1.0 – 2.5 mm

Material Width Range: 200 – 600 mm

Material Types: Galvanized Steel, Cold Rolled Steel, Mild Steel

Material Yield Strength: Up to 350 MPa (50 KSI)

Roller Material: High-grade GCr15 steel

Roller Surface Treatment: Hard chrome plated for extended wear life

Number of Forming Stations: 16–20 (based on profile requirements)

Roller Shaft Diameter: 75 mm

Shaft Material: Solid high-strength 45# steel, precision-ground

Main Drive Type: Chain drive / Gearbox drive (based on build preference)

Power (UAE): 380V, 50Hz, 3-Phase

Motor Power: 15 kW

Cutting Method: Hydraulic post-cutting system

Blade Material: Cr12MoV steel, heat-treated

Control Type: PLC control system with touch-screen interface

Operating Mode: Fully automatic with manual override

De-coiling System: Manual or hydraulic de-coiler (optional 3T – 5T capacity)

Punching/Notching System (if included): Servo-controlled inline hydraulic punching for anti-slip holes and edge slots

Machine Frame: Heavy-duty welded steel frame

Thickness of Frame Steel: 20 mm

Profile Shape: Rectangular or custom plank shape with non-slip holes

Profile Width and Depth: Width: 240–500 mm / Depth: 40–80 mm

Length Tolerance: ±1 mm

Safety Features:

Protective Covers/Guards

Emergency Stop Button

Overload Protection System

The Metal Scaffolding Planks Board Roll Forming Machine from Machine Matcher caters to the following industries:

Construction and Infrastructure

Used for temporary work platforms, scaffolding support, catwalks, and structural decking.

Industrial Maintenance & Repair

Applied in industrial plant scaffolding, maintenance platforms, and inspection bridges.

Oil & Gas and Petrochemical

Used in refinery scaffolding systems, offshore rig walkways, and access platforms.

Shipbuilding and Marine Services

Integrated into shipyard scaffolding and dockyard access applications.

Power Plants and Utilities

Required for elevated work access systems and safety platforms.

Examples of Utilization:

Scaffolding planks produced by this machine are widely used on building sites, industrial plants, and power station maintenance scaffolding structures due to their slip-resistant design, consistent strength, and corrosion resistance.

Profile shape, depth, and width tailored to customer drawings

Option for slip-resistant embossing or perforation

Automatic stacker and collecting table

Custom punching layouts

Branding/logo embossing system

Language selection on HMI interface

Upgraded automation and data tracking for ERP integration

High Durability Rollers and Shafts: Engineered with hardened GCr15 and precision-ground shafts for extended life under high loads.

Custom-Built for UAE Conditions: Power systems and material capacities are tailored for local standards and applications.

Reduced Scrap Rate: Precision-controlled feeding and cutting ensure minimal material waste.

Quick Profile Changeovers: Design flexibility allows for fast tooling changes to adapt to different plank designs.

Full Automation: Minimizes labor costs and maximizes productivity.

Service and Support in UAE: Localized customer support, remote diagnostics, and optional on-site setup ensure reduced downtime.

These advantages translate into measurable benefits:

Reduced operational costs, faster turnaround on scaffold plank production, and improved worker safety through better material uniformity.

Q: Can the machine be customized for our profile?

A: Yes. Machine Matcher builds each unit to your specific plank profile dimensions and design needs.

Q: What type of material is normally used with this machine?

A: Most commonly used materials are galvanized steel, mild steel, and cold rolled steel with thickness ranging from 1.0 mm to 2.5 mm, and yield strength up to 50 KSI (350 MPa).

Q: Is remote installation support available?

A: Yes. We offer full video support for remote installation. On-site installation in the UAE is also available on request.

Q: What is the lead time for manufacturing and shipping?

A: Manufacturing typically takes 30–60 days. Shipping times vary based on the final destination within the UAE.

Q: What affects the final price of the machine?

A: Price varies depending on your customization requirements, optional systems like punching, stackers, de-coilers, and desired automation level.

Starting Price: From USD $45,000 (average base model)

Price Influencing Factors:

Profile shape and dimensions

Punching options

De-coiler capacity

Level of automation

Motor power and drive type

Control system features

Contact us at: [email protected]

Send your profile drawings and any relevant specifications for a tailored quote.

All machines from Machine Matcher are brand new, custom-built to order, and delivered across the United Arab Emirates—including Dubai, Abu Dhabi, Sharjah, and surrounding areas. Each unit is covered by a 1-year warranty from the date of dispatch and includes ongoing support for maintenance and repair.

Machine Matcher – Your Trusted Partner in Roll Forming Solutions

When it comes to supplying reliable, high-performance roll forming machines, Machine Matcher delivers tailored equipment for the UAE market. Every scaffolding plank machine is designed to perform under rigorous industrial demands while ensuring maximum safety, productivity, and efficiency.

Let our technical team help you find the best solution for your operation—from design to delivery, Machine Matcher has you covered.

Copyright 2026 © Machine Matcher.