To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

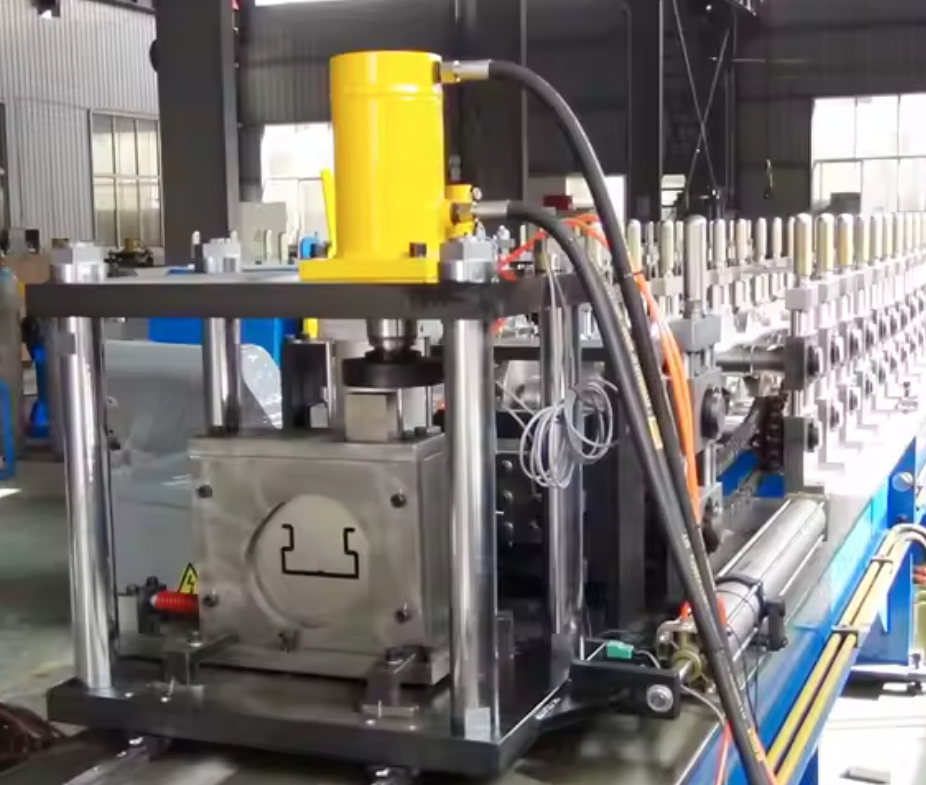

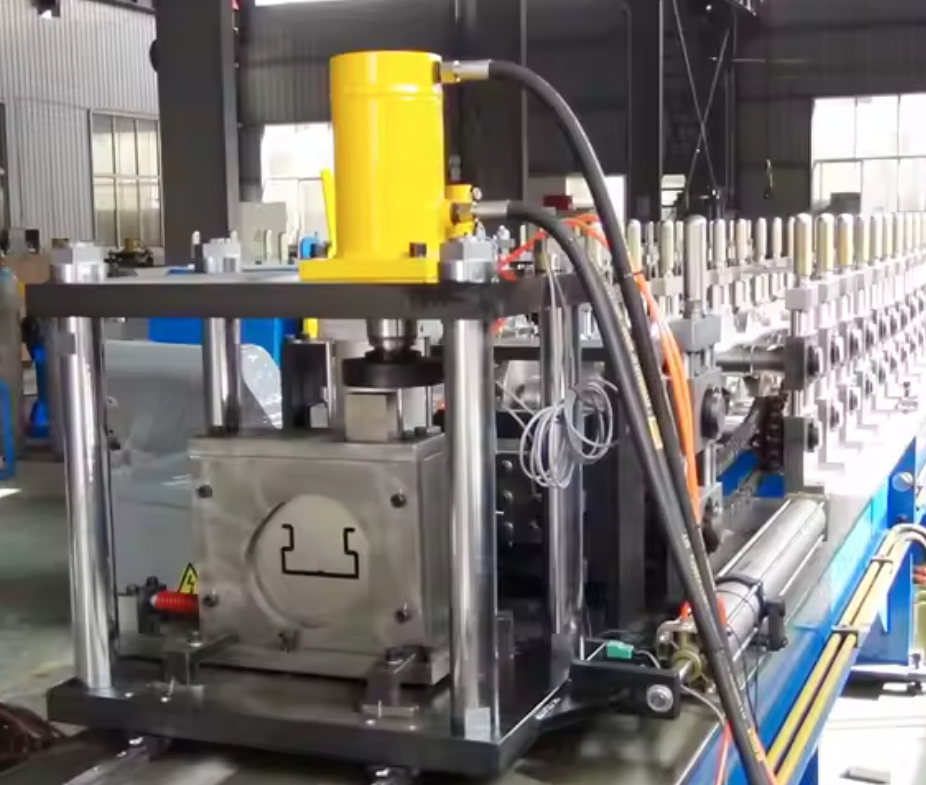

Metal Storage Rack Roll Forming Machine – United Arab Emirates

The Metal Storage Rack Roll Forming Machine is a fully automated, high-precision production system designed for the mass manufacturing of industrial-grade shelving and storage rack profiles. This machine is ideal for customers in the UAE seeking efficient, durable, and customizable roll forming solutions tailored to warehousing, logistics, and heavy-duty shelving applications.

Built to handle diverse material types and gauges, this machine ensures consistent performance under high production demands. All machines are new, made to order, and can be delivered anywhere across the UAE—including Abu Dhabi, Dubai, Sharjah, and other Emirates—directly from our manufacturing partner.

This roll forming machine caters to a wide range of industries, including:

Warehousing & Logistics

Retail & Supermarket Fixtures

Automotive Parts Storage

Industrial Manufacturing

Cold Storage & Food Warehousing

Construction Material Storage

Furniture & Display Fixtures

Creating slotted shelving profiles for adjustable storage racks

Manufacturing upright and beam profiles used in pallet racking systems

Producing light and heavy-duty shelf panels for various industrial storage solutions

This machine is capable of producing a wide variety of storage rack profiles including box shelves, slotted angle profiles, upright frames, and support beams. With in-line punching and high-speed operation, it’s built for manufacturers demanding precision, flexibility, and volume output.

Machine Type: Metal Storage Rack Roll Forming Machine

Production Speed: 10–25 meters per minute (adjustable based on profile complexity)

Material Thickness Range: 1.0 – 2.5 mm

Material Width Range: 100 – 600 mm

Material Types: Galvanized steel (GI), Cold-rolled steel (CR), Hot-rolled steel (HR), Pre-painted steel

Material Yield Strength: Up to 350 MPa (50 ksi)

Roller Material: GCr15 (high-strength steel)

Roller Surface Treatment: Hard chrome plated for wear resistance

Number of Forming Stations: 16–24 stations (customizable)

Roller Shaft Diameter: 70 mm

Shaft Material: 40Cr heat-treated

Main Drive Type: Chain or gearbox drive

Power (UAE compatible): 380V / 50Hz / 3-Phase

Motor Power: 15–22 kW depending on profile complexity

Cutting Method: Hydraulic flying cut

Blade Material: Cr12Mov (hardened and ground)

Control Type: PLC with HMI touchscreen (Siemens or Delta)

Operating Mode: Fully automatic with manual override

De-coiling System: Hydraulic or manual uncoiler (3–5 tons)

Punching/Notching System: Servo punching with multi-head tooling (optional)

Machine Frame: Welded steel structure, stress-relieved

Thickness of Frame Steel: 18–25 mm

Profile Shape: Custom shelving/rack profiles (U-channel, box, slotted angle, etc.)

Profile Width and Depth: Based on customer's drawing (typically 40–90 mm wide, 20–50 mm deep)

Length Tolerance: ±1.0 mm

Protective Covers and Safety Guards

Emergency Stop Button

Electrical Overload Protection System

Optional Light Curtains or Safety Enclosures

Common Material: Galvanized steel (GI) or Cold-Rolled Steel

Gauge Range: 14 to 20 gauge (1.2 mm to 2.5 mm)

KSI: Typically 40–50 ksi (275–350 MPa)

USD $65,000

Prices vary based on configuration, automation level, profile complexity, and included systems.

Profile customization

Punching/notching stations

Servo feeder inclusion

Coil car, stacker, or leveling system

PLC brand and control panel type

Safety features and enclosures

Profile Customization: We tailor the machine to your specific rack design, whether slotted, boxed, or perforated.

High Strength Rollers: Long-lasting GCr15 rollers with chrome coating ensure high output with minimal wear.

Servo Punching Options: Ideal for intricate shelving designs that require fast and accurate perforations.

Speed & Efficiency: Delivers consistent production with minimal scrap and high precision, helping reduce operational costs.

Turnkey Delivery to UAE: Shipped directly to any Emirate with local voltage compatibility and full support.

Reduced Manual Labor: Automation eliminates multiple stages of manual processing.

Faster Project Delivery: Rapid production leads to quicker order fulfillment.

Custom Setup: Ensures maximum ROI by only paying for required features.

Long-Term Support: One-year warranty and ongoing technical support from the Machine Matcher team.

Profile size and shape

Number and type of punching heads

Coil loading system (manual, hydraulic, or motorized)

Control panel (basic or advanced touchscreen HMI)

Servo feeder integration

Stacker or automatic packaging system

All machines are brand new and custom-built to your profile requirements. Delivery available across the UAE, including:

Dubai

Abu Dhabi

Sharjah

Ajman

Ras Al Khaimah

Fujairah

Umm Al Quwain

If you have profile drawings, shelf specifications, or gauge and size requirements, please send all details to:

We will reply with a tailored quotation and machine solution that fits your exact needs.

Q: Can this machine produce multiple types of storage rack profiles?

A: Yes, the machine can be designed for adjustable tooling or quick-change stations to allow various profiles.

Q: Is in-line punching available?

A: Absolutely. You can opt for servo punching with customizable patterns to match your shelving design.

Q: What is the power requirement for the UAE?

A: The machine is built for 380V, 50Hz, 3-phase—perfectly compatible with UAE industrial standards.

Q: How long does it take to deliver to the UAE?

A: Standard lead time is 60–75 days from deposit to delivery.

Q: Is operator training included?

A: Yes, we offer remote setup assistance and on-site operator training upon request.

Q: What kind of maintenance is required?

A: Routine lubrication, roller cleaning, and electrical checks. Our machines are built for long service intervals.

For high-speed, high-accuracy production of storage rack profiles tailored for the UAE market, this machine is your ultimate investment in durability, customization, and efficiency

Copyright 2026 © Machine Matcher.