To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Metal T Profile Roll Forming Machine – UAE

The Metal T Profile Roll Forming Machine is a precision-engineered, fully automatic solution for producing high-quality T-shaped metal profiles used widely in interior framing, ceiling grid systems, and light steel construction. Designed to serve the construction and commercial fit-out industries across the United Arab Emirates, this machine is custom-built to meet exact customer specifications and is compatible with a variety of light-gauge metals. Its robust build, high-speed operation, and advanced control systems make it ideal for large-scale production environments in Abu Dhabi, Dubai, Sharjah, and beyond.

This machine is designed for fast, continuous, and accurate forming of T-bar profiles and similar configurations used in suspended ceilings and partition systems. It features hardened rollers, advanced control systems, optional punching units, and a high-precision cutting system to ensure profile uniformity and production reliability.

Commercial construction and fit-outs

Office and retail space development

Residential building interiors

Industrial ceilings and partitions

Drywall and acoustic panel support systems

Machine Type: Metal T Profile Roll Forming Machine

Production Speed: 15–30 meters per minute (adjustable based on profile complexity)

Material Thickness Range: 0.3 mm – 0.8 mm

Material Width Range: 100 mm – 300 mm (depending on T-profile dimensions)

Material Types: Galvanized Steel (GI), Pre-painted Steel (PPGI), Aluminum

Material Yield Strength: Up to 280–350 MPa

Roller Material: GCr15 high-grade steel, heat-treated and precision-ground

Roller Surface Treatment: Hard chrome plating for wear resistance and longer life

Number of Forming Stations: 12–16 stations (customizable per profile)

Roller Shaft Diameter: 40–60 mm

Shaft Material: 45# high-strength steel, precision machined

Main Drive Type: Chain drive or gearbox drive (as per design preference)

Power (UAE): 380V / 50Hz / 3-Phase

Motor Power: 4 kW to 7.5 kW (depends on configuration and speed)

Cutting Method: Hydraulic cutting – non-stop or post-cutting

Blade Material: Cr12MoV, heat-treated for extended lifespan

Control Type: PLC control system (Siemens or Delta) with HMI touchscreen interface

Operating Mode: Fully automatic, with manual override functions

De-coiling System: Manual or hydraulic decoiler (3-ton or 5-ton optional)

Punching/Notching System (if included): Hydraulic or servo punching units (customizable per hole pattern)

Machine Frame: Welded steel structure, stress-relieved

Thickness of Frame Steel: 18–25 mm thick steel plate

Profile Shape: T-Bar / T-Grid profile

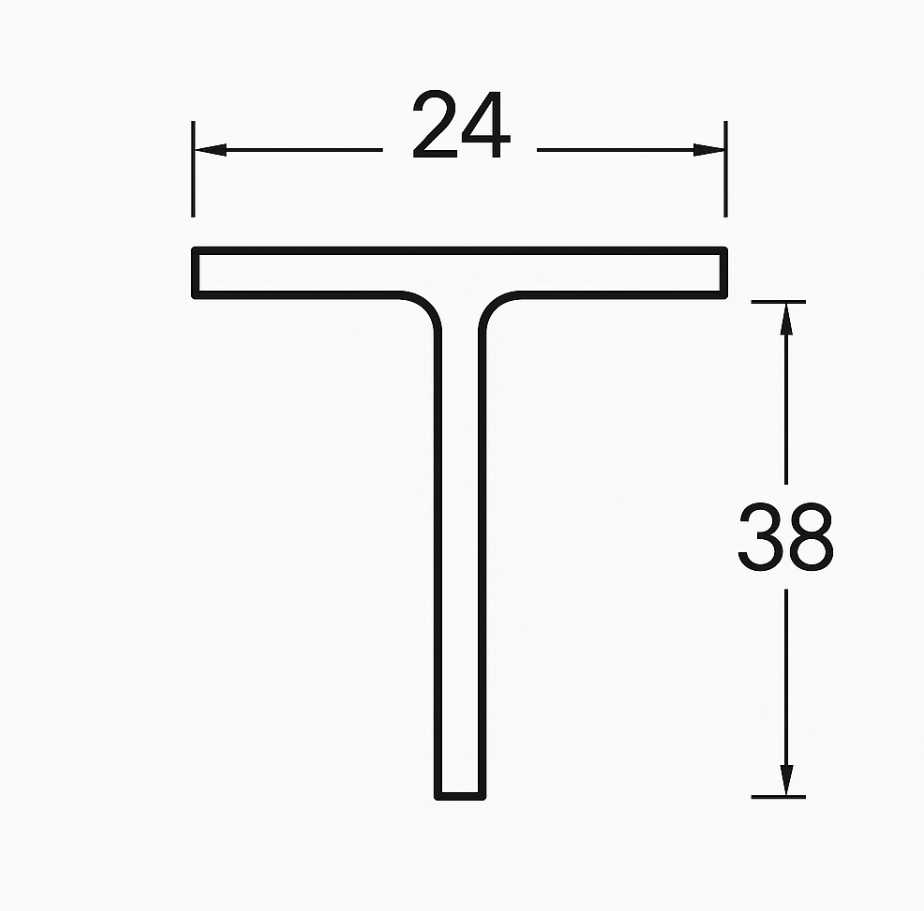

Profile Width and Depth: Customizable – e.g., 24 mm x 38 mm, 24 mm x 32 mm

Length Tolerance: ±1 mm per 3 meters

Safety Features:

Protective Covers/Guards

Emergency Stop Button

Overload Protection System

Prices Start From: USD 25,000 (FOB) for standard models

What Affects Final Price:

Profile complexity and customization

Required automation level

Punching and cutting options

Material handling systems (coil car, stackers, etc.)

Delivery destination and installation support

Location & Availability:

All machines are new, custom-built to your profile specifications, and available for delivery anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, Ajman, Ras Al Khaimah, Fujairah, and Umm Al Quwain. Machines are manufactured in partnership with top global suppliers and delivered with full documentation, wiring diagrams, and support.

Warranty and Support:

Each machine is backed by a 1-year warranty from the date of dispatch and includes remote setup assistance, spare parts support, and optional in-country technician visits.

To receive the best possible quote, please email your profile drawing, thickness, material type, voltage needs, and delivery location to:

Q: What profile sizes can the T-Bar roll forming machine produce?

A: The machine can be customized to produce various standard T-profile sizes such as 24x38mm, 24x32mm, or any dimension specified in your drawing.

Q: Can this machine include a punching unit for slots or holes?

A: Yes, optional hydraulic or servo punching systems can be integrated based on your required hole patterns.

Q: How long does it take to manufacture and deliver the machine to the UAE?

A: The standard lead time is 45–60 days from order confirmation, including manufacturing, testing, and shipping.

Q: Is installation and training provided?

A: Yes, remote training is included, and on-site setup support is available upon request.

Q: What is the power requirement for the machine in the UAE?

A: The machine is configured for 380V, 3-phase, 50Hz, matching the local power standard in the UAE.

Q: Can I run aluminum or pre-painted coils on this machine?

A: Yes, the machine is compatible with aluminum and pre-painted steel coils within the specified thickness and yield strength range.

Lightweight suspended ceilings in malls, airports, and hospitals

Fast and precise manufacturing for fit-out contractors

Drywall and ceiling installers needing custom lengths

Bulk production for export or high-volume real estate projects

If you are looking for a reliable, automated, and high-precision roll forming solution for T-profile production in the UAE, this machine is your answer. Machine Matcher works with top-tier manufacturers to customize your machine based on specific requirements and deliver directly to your facility.

Copyright 2026 © Machine Matcher.