To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

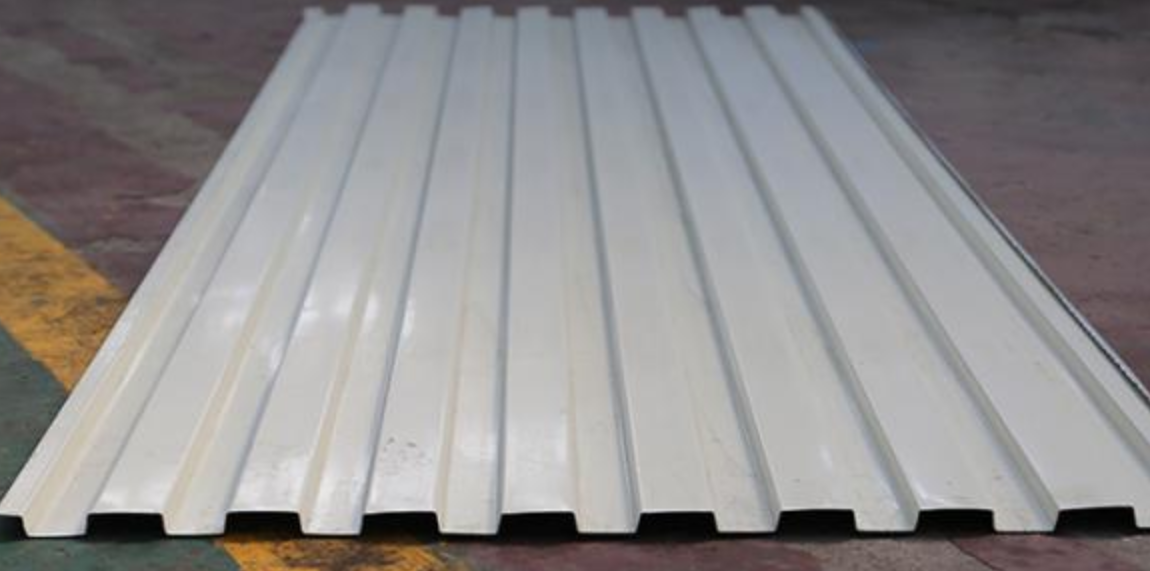

The Australian Saudi Style Rolling Shutter Door Machine is designed for high-performance production of rolling shutter doors, primarily used in garages, villas, and shops. This machine takes inspiration from Australian shutter designs, particularly the industry-leading solutions from B&D, ensuring premium quality and durability for the demanding conditions of the Middle Eastern climate.

These rolling shutters are built to offer both manual and electronic operation options, with an integrated auto-reversing safety system for enhanced safety and reliability. The doors are engineered to be waterproof, providing long-lasting protection against the elements. With the ability to customize based on your drawing profiles, this machine is versatile and adaptable to various requirements.

Machine Type: Australian Saudi Style Rolling Shutter Door Machine

Usage: Designed to support steel coils and uncoil them in a smooth and efficient manner, ensuring precision and shape retention.

Coil Uncoiling: Passive uncoil system pulled by the roll forming system.

Loading Capacity: 5T

Uncoiling Width: 400mm

Inner Diameter: 450-508mm

Voltage: 380V 50Hz 3Phase

Frame Material: 400H Steel

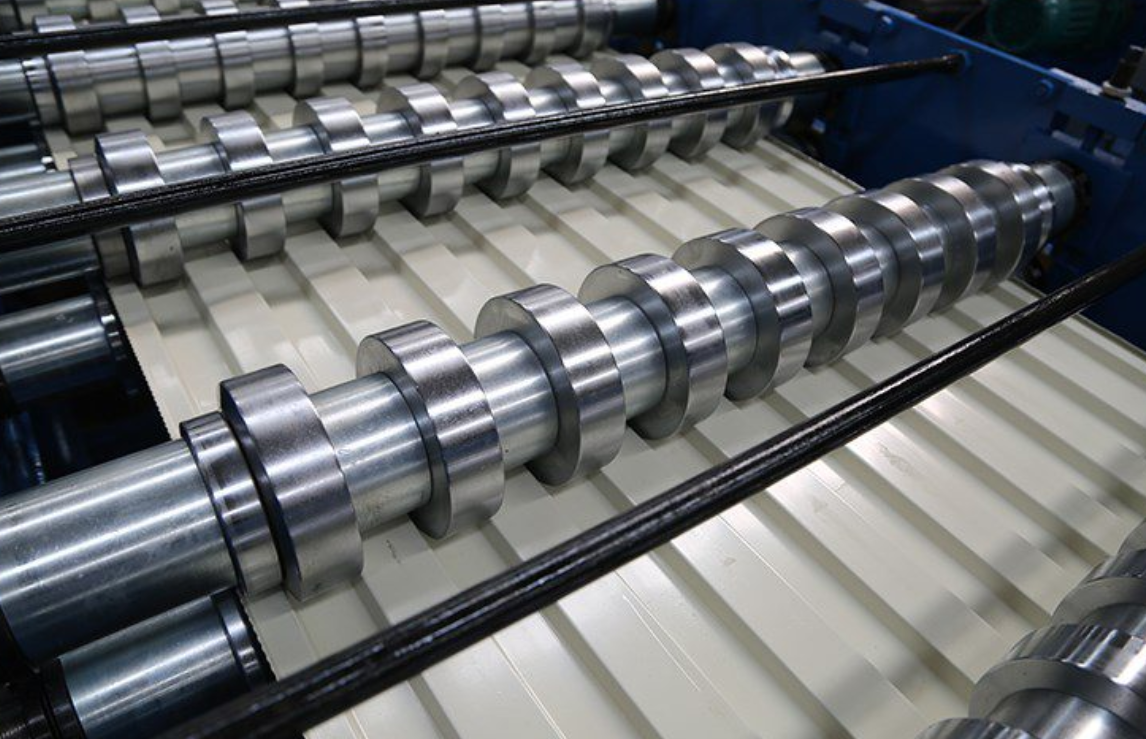

Drive Mode: Chain drive system for precision

Roller Material: 45# steel with surface hard chromium plating

Shaft Material: 45# steel with tempering

Shaft Diameter: φ70mm

Number of Rollers: 25

Main Power: 15kw (cycloidal planetary gear speed reducer)

Decoiler: Manual or hydraulic options available for uncoiling steel coils.

Roller Fixer: Guide column to ensure stability during production.

Main Frame: Heavy-duty 400H steel frame for durability.

Motor & Drive System: Powerful 15kw motor with chain drive for reliable operation.

Rollers: 25 high-quality rollers made from 45# steel with chromium plating for smooth, high-precision shaping.

Garages: Ideal for villa and residential garage installations.

Shops & Commercial Properties: Widely used for shopfronts due to their durability and smooth operation.

Middle Eastern Climate Adaptation: Engineered to withstand high temperatures and humidity, ensuring long-term reliability.

Heavy-Duty Construction: Designed to handle heavy loads with precision.

Customization: Machine design can be adjusted based on profile drawings and material specifications.

Safety Standards: Includes an auto-reversing safety feature for enhanced operation security.

Length of Main Part: Approx. 12000x1700x1500 mm

Weight of Main Part: 5 tons

Main Power: 15kw with a cycloidal planetary gear speed reducer

Number of Rollers: 25

Price Range: The price for the Australian Saudi Style Rolling Shutter Door Machine typically ranges from USD 35,000 to USD 50,000, depending on customization and additional features such as automation options and auxiliary parts.

Machine Matcher offers full assistance with the installation and commissioning of the machine. Our engineers are available for on-site support, ensuring proper setup, calibration, and training for your team. We provide detailed instructions and remote support for hassle-free operation.

Operation: The machine operates with high precision and reliability, driven by an automated chain system.

Maintenance: Regular cleaning and lubrication of rollers and shafts are recommended. The machine’s hard chromium-plated rollers minimize wear and extend its lifespan.

Material Type and Gauge: Ensure your material specifications match the machine’s capabilities.

Production Volume: This machine is suitable for both small-scale and high-volume production.

Power Supply: Verify compatibility with the required voltage for your location.

Durability: Built to withstand harsh climates and frequent use.

Precision: Maintains product shape and surface quality with a well-calibrated chain and roller system.

Safety Features: Equipped with an auto-reversing system for enhanced safety.

Initial Investment: Higher initial cost compared to some other shutter door machines.

Space Requirements: Requires a large installation space due to its heavy-duty frame and rollers.

Compared to similar machines in the market, this Australian Saudi Style Rolling Shutter Door Machine offers competitive pricing while ensuring top-tier quality and durability.

Uneven Shaping: This may be caused by misalignment of rollers or insufficient lubrication. Ensure regular maintenance to prevent this issue.

Motor Overload: If the motor is working intermittently, check the voltage supply and the load capacity.

This machine is available for global delivery. Machine Matcher provides comprehensive shipping assistance, including documentation and customs clearance, ensuring a seamless delivery process.

Machine Matcher is dedicated to assisting buyers in finding the perfect roll forming machine for their specific needs. Here's how we help:

Tailored Matching: We match your profile drawings, material gauges, and project specifications with the best machine options available globally.

Trusted Global Network: We source machines from leading manufacturers worldwide, offering competitive pricing and guaranteed quality.

Comprehensive Support: From setup, shipping, and installation to after-sales support, we guide you through the entire process.

For more information or to request a quote, feel free to reach out:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Website: www.machinematcher.com

Q: How long does installation take? A: Typically, installation takes about 2-3 days, depending on the complexity and customization required.

Q: Can the machine handle different types of steel coils? A: Yes, the machine can handle a variety of steel coils with different gauges. The machine can be customized to suit your specific coil requirements.

Q: What is the warranty period for this machine? A: The machine comes with a standard 1-year warranty covering parts and manufacturing defects.

Q: Is the machine available for global delivery? A: Yes, we provide worldwide shipping assistance with all the necessary documentation and customs clearance.

Copyright 2026 © Machine Matcher.