To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

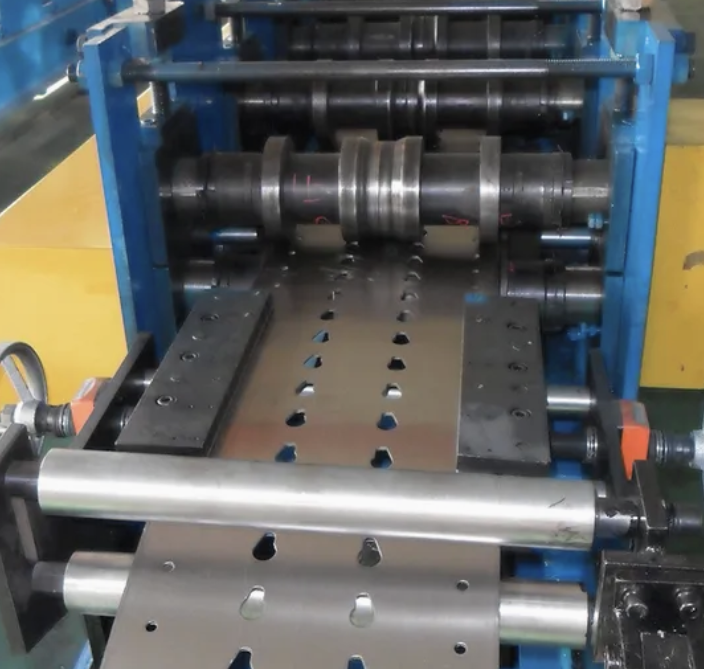

A pallet racking roll forming machine is designed to manufacture the frames, beams, and other structural components used in pallet rack storage systems. Here’s an overview of its specifications and description:

The pallet racking roll forming machine is a fully automated system designed for high-precision production of pallet racking components. It processes steel coils and forms them into the desired rack profiles through a series of rollers. The machine includes a decoiler, leveling device, roll forming system, hydraulic cutting system, and an output table.

Key Features:

This machine is ideal for manufacturers of warehouse storage systems who require large-scale production of pallet racking with consistent quality and precision.

Copyright 2026 © Machine Matcher.