To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

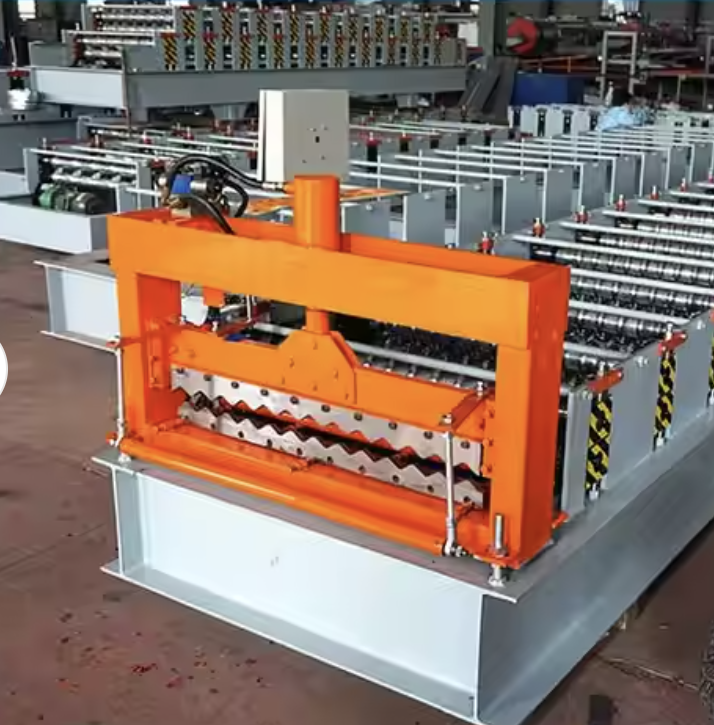

A panel roll forming machine is an advanced industrial machine designed to fabricate metal panels used in roofing, cladding, and walling applications. These machines are equipped to create profiles with precise dimensions, consistency, and quality. The versatility of the machine makes it a preferred choice for industries such as construction, agriculture, and infrastructure development.

This machine operates by feeding metal sheets through a series of rollers, which gradually shape the material into the desired profile. It provides high productivity, minimal material waste, and enhanced accuracy. Common materials used in panel roll forming machines include galvanized steel, aluminum, and stainless steel.

Here is a detailed breakdown of the key specifications of a panel roll forming machine:

Q1: What materials can be used in a panel roll forming machine?

A: Common materials include galvanized steel, aluminum, stainless steel, and pre-painted coils. The machine can be adjusted for material thickness and width to suit various applications.

Q2: How do I choose the right panel roll forming machine?

A: Consider factors such as the desired panel profile, material type, production speed, and budget. Ensure the machine meets your technical requirements and quality standards.

Q3: What are the maintenance requirements?

A: Regular maintenance involves lubrication of rollers and moving parts, inspection of electrical systems, and cleaning to prevent debris buildup. Periodic calibration ensures consistent profile accuracy.

Q4: Can this machine produce multiple profiles?

A: Yes, many panel roll forming machines come with adjustable features or interchangeable rollers to create different profiles, such as trapezoidal, corrugated, and standing seam panels.

Q5: What is the average lifespan of a panel roll forming machine?

A: With proper maintenance, a high-quality panel roll forming machine can last 10–15 years or more.

Q6: Are these machines energy efficient?

A: Modern machines are designed with energy-efficient motors and control systems to minimize power consumption.

Q7: How do I ensure consistent panel quality?

A: Use high-quality input materials, regularly calibrate the machine, and maintain the rollers and cutting systems in good condition.

Copyright 2026 © Machine Matcher.