To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

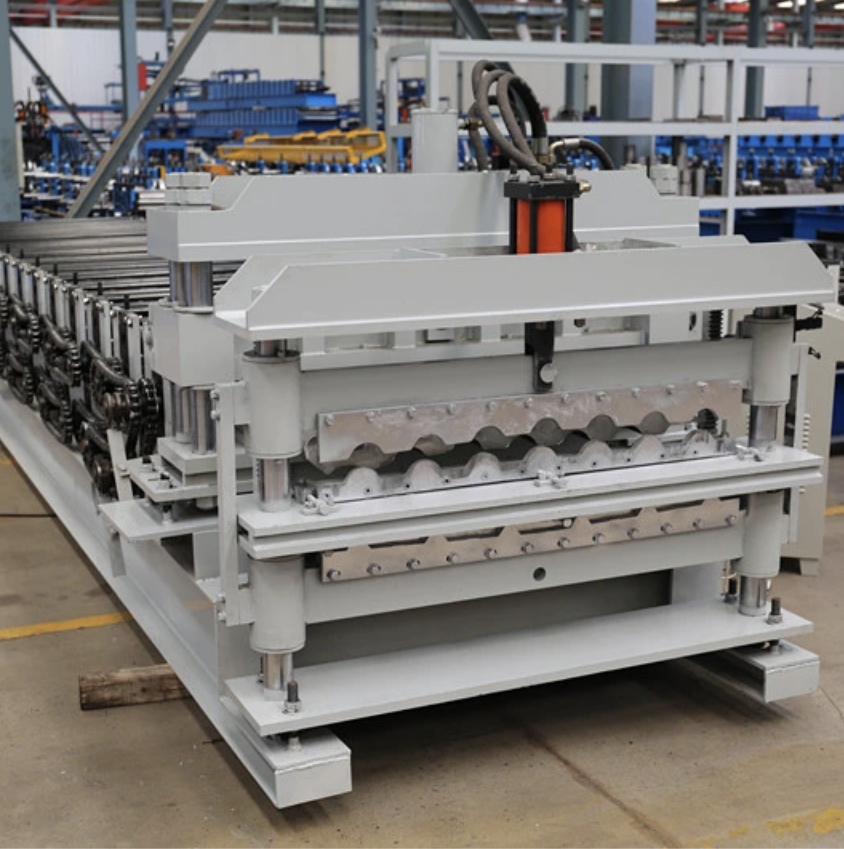

Longspan Roof Panel Roll Forming Making Machine

1. Nice appearence.

2. Low noise.

3. High efficiency.

4. Good quality.

5. Esay control.

Man-made uncoiler-Roll forming machine-compture control system-hydraulic control system-form cutter

Guiding device

Adopt guiding bar and sliding block to control the width and position of the steel sheet. The coil is guided in the correct position and passed to the roll forming system. Can adjust the guiding bar with loosing the fixing bolts to feed sheet in right position. It's fixed structure to make sure can not move easily.

Roll Forming System:

Roll forming system consist of machine frame, transmission system, electrical motor and roll forming system.

A. Machine frame adopts welding structure with shot blasting and painting treatment

B. All rollers material adopt high quality No. 45 steel, with hard chrome coated on surface, all treatment by full CNC machines, to make sure the rollers with good rigidity and precision, and form perfect roofing sheet as per design.

C. All rolling shafts are made by high quality No. 45 steel with quench and temper treatment, so the shafts with good rigidity which could use for long tern without deformation.

D. Rolling shafting supporting structure type is steel wall and welded with the basement together to have rigidity.

E. Cycloidal pin gear speed reducer motor driven, the back/forward roller driven by chain, part of upper/lower rollers driven by gear

F. Adjust the screw bar manually to adjust the distance between upper/lower rollers for difference thickness of sheet.

(Attention: All rolling system has adjusted in our company as a perfect situation, we don't suggest to adjust the rollers at random, if necessary, should adjust by a experienced technician or after train by our engineer. Otherwise will cause the machine can not form a good profile

Last station should be like this there is no space between

Cutting device

A. Adopts post cutting, the cutting blade material is Cr12 with quenched treatment, after cutting, there is no material wasted.

B. Adopts welded frame for good rigidity.

C. The cutting action is droved by the power from hydraulic station which guarantees the procession of the cutting and low noisy, long life.

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job.

The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves.

Power of the oil pump: 3kw

Hydraulic oil: 40#

PLC control system

| Suitable to process | Steel plate |

| Rollers | 28rows |

| Dimensions | 11*1.2*0.9m |

| Power | 3kw(2sets) cycloidal needle wheel type |

| Diameter of the roller | ¢70mm |

| Frame of the machine | Welded 300H steel side board is made of 16mm steel structure |

| Cutting to length | using flying saw cutting |

| Decoiler: Expansion type | max ,loading1-2T |

| Voltage | 380V 50Hz |

Copyright 2026 © Machine Matcher.