To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

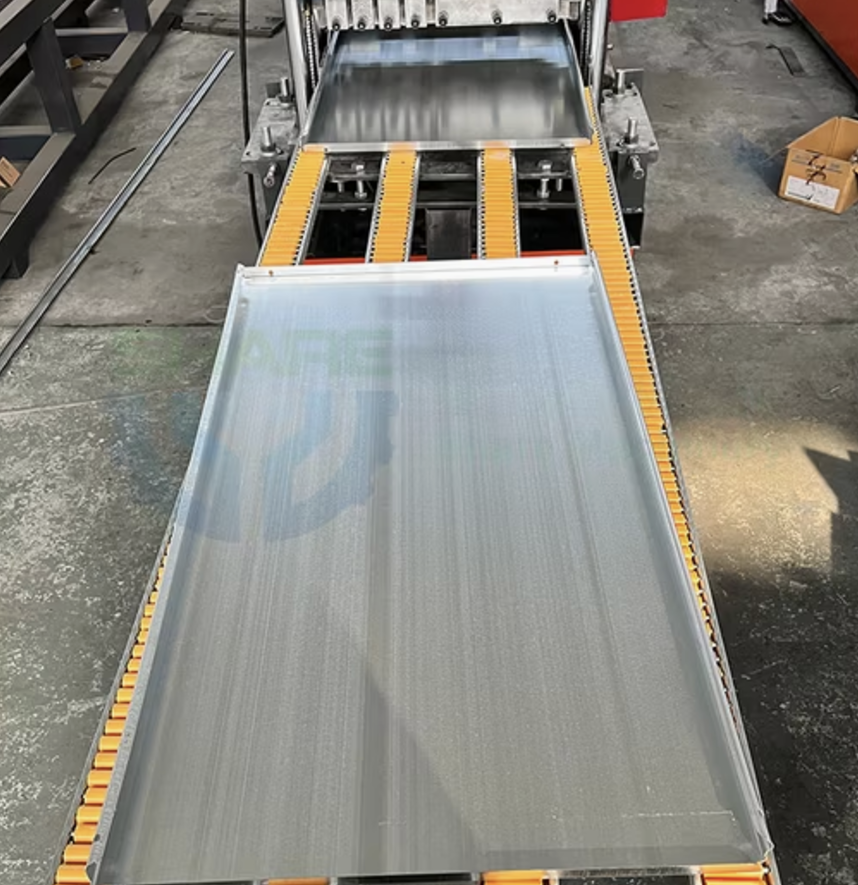

Rack roll forming machines are specialized equipment designed to produce high-quality, uniform, and durable racks used in various industries, such as warehouses, retail, and logistics. These machines streamline production by forming steel or aluminum profiles into rack structures with precise dimensions and finishes. With the growing demand for efficient storage solutions in Canada, rack roll forming machines play a critical role in supporting industries like manufacturing, distribution, and retail.

A rack roll forming machine transforms raw metal coils into ready-to-assemble rack components. This fully automated system ensures accuracy and consistency, reducing material waste and production time. The machine can produce different rack styles, such as upright racks, beams, and shelving panels, depending on the tooling and design.

Rack roll forming machines are widely used across Canada for industries like:

Q1: What is the cost of a rack roll forming machine in Canada?

A: The cost varies based on specifications and optional extras but typically ranges from CAD 150,000 to CAD 400,000.

Q2: What power requirements are needed?

A: A three-phase power supply with 380V or 480V is commonly required.

Q3: Can the machine handle custom rack designs?

A: Yes, most machines can be customized with specific tooling to produce unique rack profiles.

Q4: How long does installation take?

A: Installation and setup usually take 1-2 weeks, depending on the machine's complexity.

Q5: Are spare parts available locally in Canada?

A: Many manufacturers or distributors in Canada stock spare parts or can arrange expedited shipping.

Q6: Is operator training included with the purchase?

A: Many suppliers provide training as part of the installation package.

Q7: What industries benefit most from these machines in Canada?

A: Warehousing, logistics, retail, and industrial manufacturing sectors.

Rack roll forming machines are indispensable for efficient storage solutions in Canada’s diverse industries. By automating the production process, these machines offer significant cost savings and enhanced productivity, meeting the growing demand for high-quality racks across the country.

Copyright 2026 © Machine Matcher.