To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

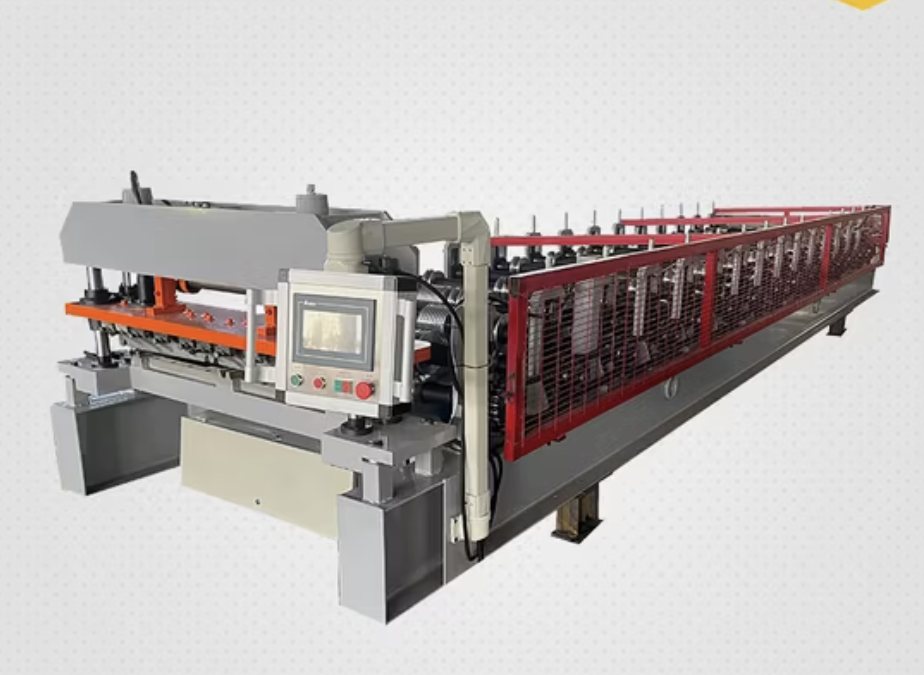

A Ribtile Roll Forming Machine is a specialized piece of equipment designed to manufacture ribtile roofing sheets, widely used in the construction and roofing industry. These sheets are known for their durability, weather resistance, and aesthetic appeal. The machine converts metal coils into uniformly profiled ribtile sheets with precision, ensuring consistency and high production efficiency.

The ribtile profile is characterized by ribbed patterns that enhance strength and rigidity, making it ideal for residential, commercial, and industrial applications. The machine is equipped with advanced technology for seamless operations and can be customized to meet specific profile and production requirements.

Q1: What materials can a ribtile roll forming machine process?

A1: The machine can process galvanized steel, color-coated steel, aluminum, and stainless steel with thicknesses ranging from 0.3 mm to 0.8 mm.

Q2: What is the maximum production speed of the machine?

A2: The maximum forming speed is 20 meters per minute, depending on the material and thickness.

Q3: Can the machine be customized for different profiles?

A3: Yes, the machine can be customized to produce various ribtile profiles based on customer requirements.

Q4: Is it possible to operate the machine remotely?

A4: Yes, with the optional remote PLC system, the machine can be monitored and operated remotely.

Q5: What are the power requirements?

A5: The standard power requirement is 380V/50Hz/3 Phase, but it can be customized to meet other specifications.

Q6: How much space is needed for installation?

A6: The machine requires a space of approximately 12 meters in length, 2 meters in width, and 2 meters in height.

Q7: What safety features are included?

A7: The machine is equipped with safety enclosures, emergency stop buttons, and an overload protection system to ensure operator safety.

Copyright 2026 © Machine Matcher.