To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

For the Egyptian market, a ridge cap roll forming machine can be tailored to meet specific requirements, considering local materials, power supply preferences, and market trends. Here’s an outline of a suitable machine along with essential specifications:

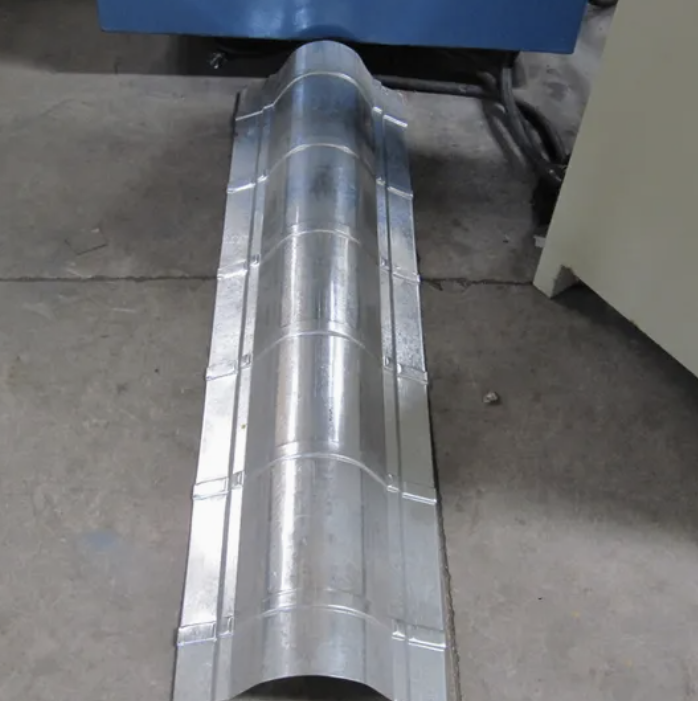

A ridge cap roll forming machine for the Egyptian market is designed to produce high-quality metal ridge caps used in roofing structures. These ridge caps offer protection and sealing to roof joints, preventing water leakage and enhancing the roof's durability. The machine typically uses galvanized steel, aluminum, or pre-painted steel, which aligns with the Egyptian roofing industry standards. The machine is also optimized to meet local preferences for energy efficiency, durable construction, and minimal maintenance.

This ridge cap roll forming machine offers a robust and efficient solution tailored to meet the needs of Egyptian roofing manufacturers, providing long-lasting and precise ridge caps essential for high-quality roofing projects.

Copyright 2026 © Machine Matcher.