To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

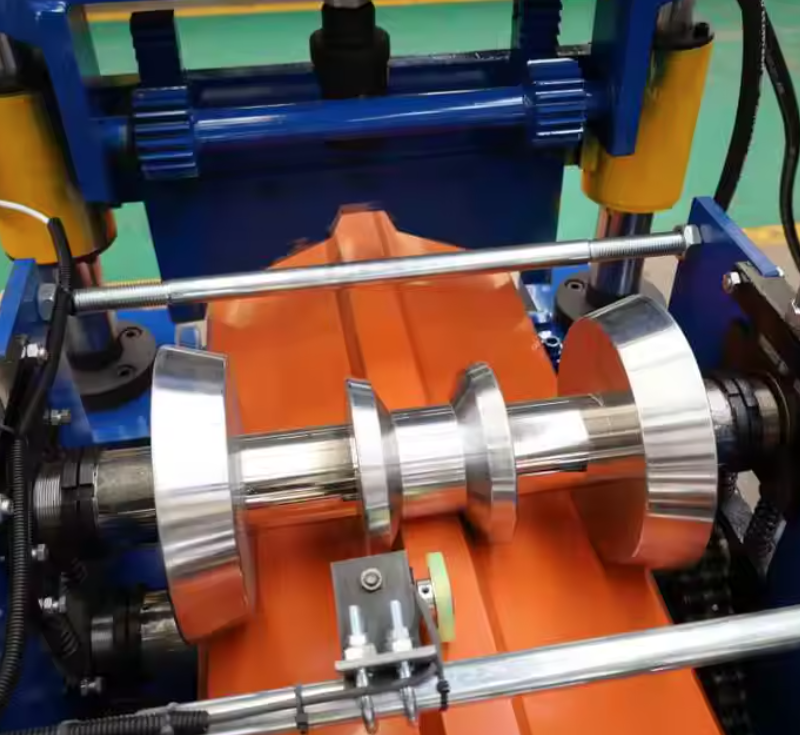

Ridge Cap Roll Forming Machine – SUAE Delivery Available

Machine Matcher proudly offers a high-performance Ridge Cap Roll Forming Machine, engineered for precision and reliability. Tailored to meet the roofing industry's demands, this machine is ideal for producing ridge caps essential for sealing roof peaks. We ensure delivery across the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah.

Our Ridge Cap Roll Forming Machine caters to various sectors:

Construction & Roofing: Manufactures ridge caps for metal roofing systems, ensuring weatherproofing and structural integrity.

Pre-Engineered Buildings: Produces components for modular structures, promoting efficiency and durability.

Agricultural Facilities: Creates roofing elements for barns, silos, and storage units.

Industrial Warehouses: Supplies ridge caps for large-scale storage and manufacturing facilities.

This roll forming machine is designed to produce ridge caps with high precision and consistency. Its robust construction and advanced features ensure seamless operation, making it suitable for both small-scale and large-scale production.

Machine Type: Roll Forming Machine for Ridge Caps

Production Speed: 5–15 meters per minute

Material Thickness Range: 0.3–0.8 mm

Material Width Range: 610–1220 mm

Material Types: PPGI, PPGL, GI, GL, Aluminum

Material Yield Strength: 235–550 MPa

Roller Material: 45# Steel with Chromium Plating

Roller Surface Treatment: Hard Chrome Coating

Number of Forming Stations: 12–16 (depending on profile)

Roller Shaft Diameter: 55–70 mm

Shaft Material: 45# Steel

Main Drive Type: Chain Drive

Motor Power: 4–7.5 kW

Cutting Method: Hydraulic Post-Cutting

Blade Material: Cr12 Mold Steel, Quenched Treatment

Control Type: PLC with Touchscreen Interface (Mitsubishi or Delta)

Operating Mode: Automatic with Manual Override

De-coiling System: Manual or Hydraulic Decoiler (3–5 tons capacity)

Punching/Notching System: Optional, based on customization

Machine Frame: 350–400 H-Beam Steel

Thickness of Frame Steel: 16–20 mm

Profile Shape: Customizable to client specifications

Profile Width and Depth: Based on provided profile drawings

Length Tolerance: ±1.0 mm

Safety Features:

Protective Covers/Guards

Emergency Stop Button

Overload Protection System

Machine Matcher offers extensive customization to meet specific production needs:

Profile Design: Tailored to match unique ridge cap profiles.

Material Compatibility: Adjustments for different material types and thicknesses.

Automation Level: Options for increased automation and integration with existing production lines.

Voltage and Power Requirements: Configured to match local power standards in the UAE.

Precision Engineering: Ensures consistent product quality with minimal maintenance.

High Efficiency: Optimized for rapid production without compromising accuracy.

Robust Construction: Built with high-quality materials for longevity and durability.

Comprehensive Support: Includes remote installation guidance and optional on-site setup.

Delivery Locations: Across the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah.

Installation Support: Remote video guidance provided; on-site installation available upon request.

Warranty: One-year warranty from dispatch date, with ongoing maintenance and repair support.

Starting Price: Approximately $25,000 USD.

Final Price Factors:

Customization requirements.

Optional features and add-ons.

Shipping and installation services.

For a tailored quote, please provide your specific requirements.

Q: Can the machine be customized for our profile?

A: Yes, Machine Matcher specializes in customizing machines to match your specific ridge cap profiles.

Q: What materials are compatible with this machine?

A: The machine is compatible with PPGI, PPGL, GI, GL, and Aluminum materials, ranging from 0.3 to 0.8 mm in thickness.

Q: What is the lead time for manufacturing and shipping?

A: Production typically takes 30–60 days. Shipping time varies based on the destination port in the UAE.

Q: Is remote installation support available?

A: Yes, we offer remote video guidance for installation. On-site installation services are also available upon request.

Q: What is the warranty period?

A: All machines come with a one-year warranty from the date of dispatch, along with durable maintenance and repair support.

For detailed quotations and customization options, please send your profile drawings and requirements to:

Email: [email protected]

Machine Matcher is your trusted provider for high-quality Ridge Cap Roll Forming Machines in the UAE.

Copyright 2026 © Machine Matcher.