To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

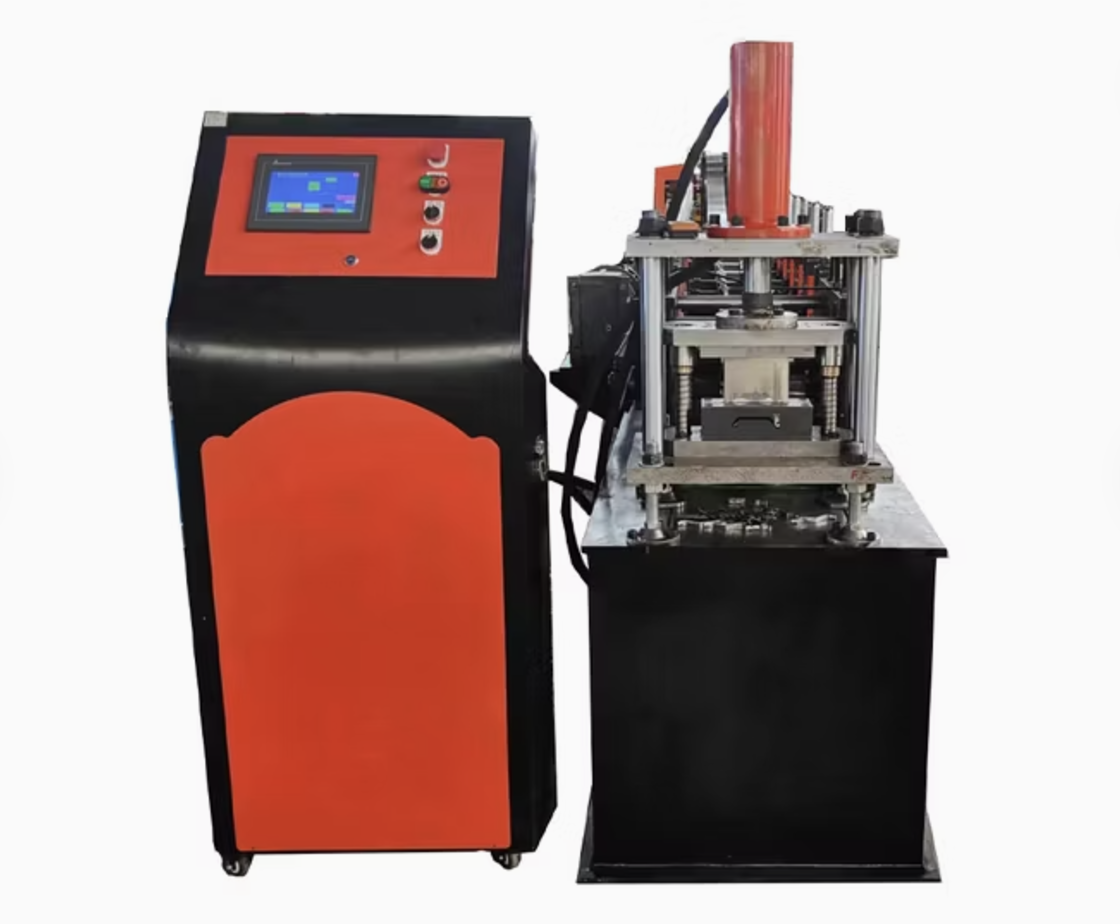

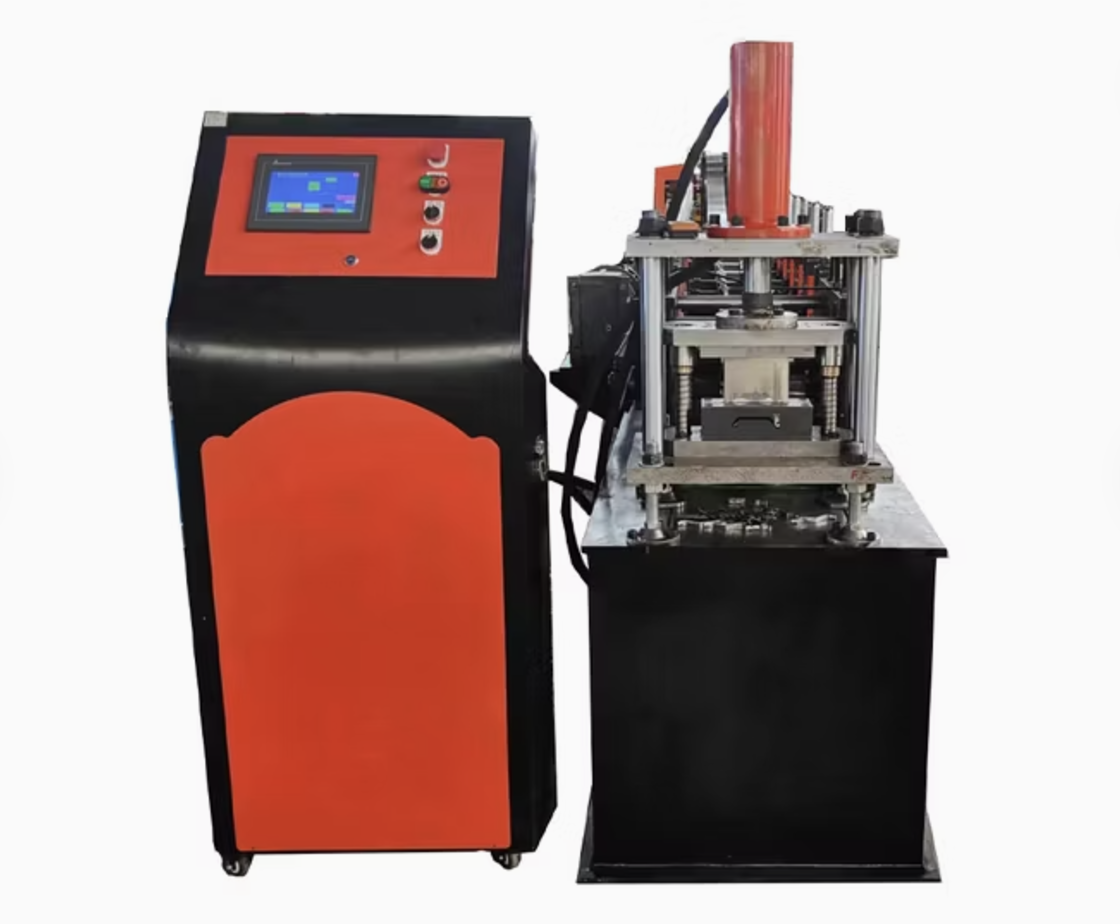

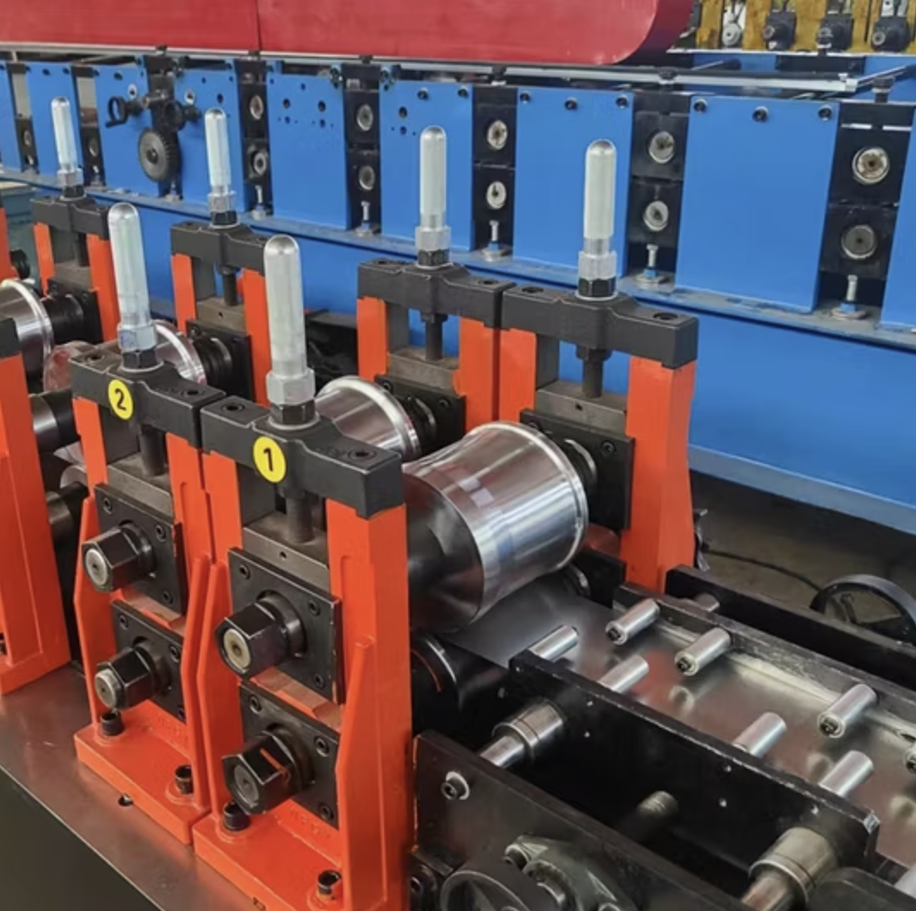

The roller shutter door roll forming machine is designed to produce high-quality roller shutter slats for industrial, commercial, and residential applications. These slats are widely used in rolling shutter doors due to their strength, durability, and space-saving design. The machine is engineered for precision, efficiency, and long-term operation, making it an ideal choice for manufacturers in Libya.

This machine can handle various raw materials such as galvanized steel, stainless steel, and aluminum with varying thicknesses. It features a fully automated process, starting from feeding the material to forming and cutting the slats into desired lengths. The machine ensures consistent quality, helping manufacturers meet local and international market demands.

Roller shutter doors produced by this machine are used in:

Copyright 2026 © Machine Matcher.