To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Roller Shutter Door Roll Forming Machine – UAE Edition

Precision-Engineered for the UAE's Industrial and Commercial Needs

The Roller Shutter Door Roll Forming Machine is a robust, high-performance system designed to manufacture interlocking slats used in roller shutter doors. Engineered for high productivity and long-term durability, this machine caters to the growing demand for secure and space-saving door solutions across residential, commercial, industrial, and logistics sectors throughout the United Arab Emirates.

Whether you are manufacturing rolling shutters for warehouses in Sharjah, retail storefronts in Dubai, or parking facilities in Abu Dhabi, this roll forming solution delivers consistent, precision-formed profiles with minimal labor and downtime.

Machine Type: Roller Shutter Door Roll Forming Machine

Production Speed: 10–20 meters per minute (depending on profile and material)

Material Thickness Range: 0.5–1.2 mm

Material Width Range: 100–300 mm (depending on profile design)

Material Types: Galvanized steel, pre-painted steel, aluminum

Material Yield Strength: Up to 350 MPa (50 ksi)

Roller Material: High-grade GCr15 steel

Roller Surface Treatment: Hard chrome plating for anti-corrosion and smooth finish

Number of Forming Stations: 12–18 stations

Roller Shaft Diameter: 60 mm

Shaft Material: 45# steel, precision ground and tempered

Main Drive Type: Chain drive / gearbox drive (as per customization)

Power (UAE Compatible): 380V / 50Hz / 3 Phase

Motor Power: 7.5 kW – 11 kW

Cutting Method: Hydraulic cutting after forming

Blade Material: Cr12Mov, heat-treated

Control Type: PLC automatic control system (Siemens or Delta)

Operating Mode: Fully automatic with touchscreen HMI

De-coiling System: Manual or hydraulic uncoiler (3–5 tons optional)

Punching/Notching System: Optional inline hydraulic punching for lock holes or ventilation slots

Machine Frame: Welded steel structure, heavy-duty

Thickness of Frame Steel: 16–20 mm

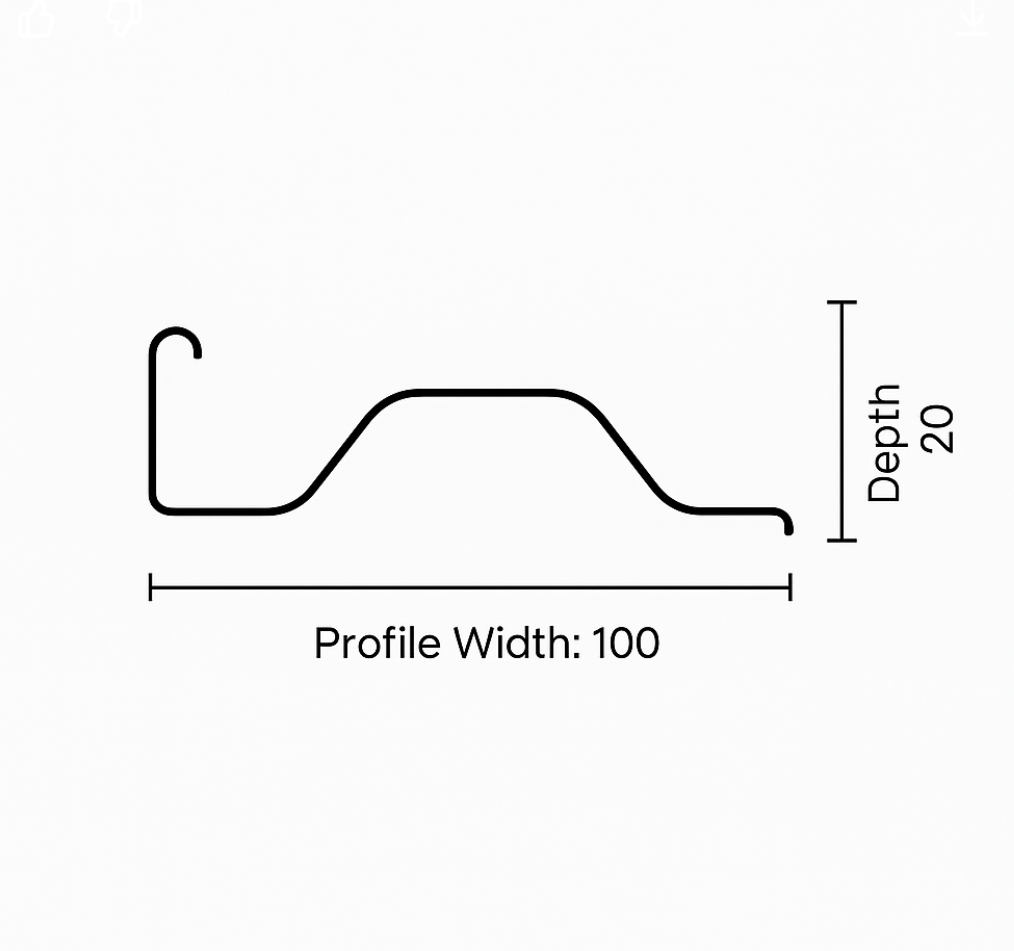

Profile Shape: Interlocking roller shutter slat

Profile Width and Depth: Varies by profile; most common 75–120 mm cover width

Length Tolerance: ±1.0 mm

Safety Features:

Protective Covers/Guards

Emergency Stop Button

Overload Protection System

Materials Used:

Galvanized Steel (G90 or G60)

Pre-painted Steel

Aluminum Alloy Sheets

Typical Gauges:

0.6 mm, 0.8 mm, 1.0 mm

Yield Strength: 33–50 ksi depending on material

Roller shutters for homes, garages, and villas

Security shutters for malls and shops

Factory door closures

Loading bay access systems

Security shutters for storefronts and kiosks

Reinforced roller shutters for secure zones

Automated roller shutters for underground or multi-story car parks

Each industry benefits from the machine’s fast profile changeover, high output, and consistency in producing shutter slats that are durable, weather-resistant, and tamper-proof.

Custom-Built to Client Profiles – Every machine is designed to match your exact roller shutter slat dimensions, ensuring perfect results every time.

Local Power Compatibility – Built to run on the UAE's 380V/50Hz grid.

Heavy-Duty Frame Design – Guarantees long operational life, even in demanding industrial environments.

Hydraulic Cutting System – Ensures clean, burr-free cuts with minimal waste.

Automated PLC Controls – Reduces manual errors and increases production efficiency.

Optional Punching Systems – Add lock holes or air slots inline without separate stations.

1-Year Warranty + After-Sales Support – All machines include 12-month warranty coverage and lifetime technical guidance.

Cost Saving Advantage:

The automation and precision of this machine minimize scrap rate, reduce manual labor, and increase production speed — helping UAE-based shutter manufacturers deliver faster and at lower cost.

Starting Price Range: $38,000 USD

Prices vary depending on the profile, width range, punching systems, decoilers, and level of automation required.

Profile width and locking type

Manual vs. automatic uncoiler

Optional embossing roller

Online punching for ventilation or keyholes

Coil car and stacker integration

Remote diagnostics and touchscreen language settings (Arabic available)

All machines are new and custom-built to match your specific requirements.

We ship directly to Abu Dhabi, Dubai, Sharjah, and all other emirates in the UAE.

All machines are covered by a one-year warranty from the date of dispatch.

Ongoing support is available for maintenance, repairs, and spare parts.

To receive a customized quote, please email your roller shutter slat drawing, material details, width and gauge, and any specific features to:

[email protected]

Our team will help match the best machine configuration for your production.

Q: Can this machine produce multiple slat profiles?

A: Yes, the machine can be designed with quick-change tooling or additional stations for alternate profiles.

Q: What kind of maintenance is required?

A: Regular lubrication, roller cleaning, and periodic hydraulic oil checks are essential for longevity. Our team provides a full maintenance guide.

Q: Can I use aluminum with this machine?

A: Yes, this machine works with both aluminum and steel sheets, provided material thickness and hardness are specified in advance.

Q: How long is the production lead time?

A: Lead time ranges from 40–60 days depending on complexity and customization.

Q: Can Machine Matcher assist with installation in the UAE?

A: Yes, we offer remote setup assistance and can arrange on-site commissioning support where required.

Copyright 2026 © Machine Matcher.