To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

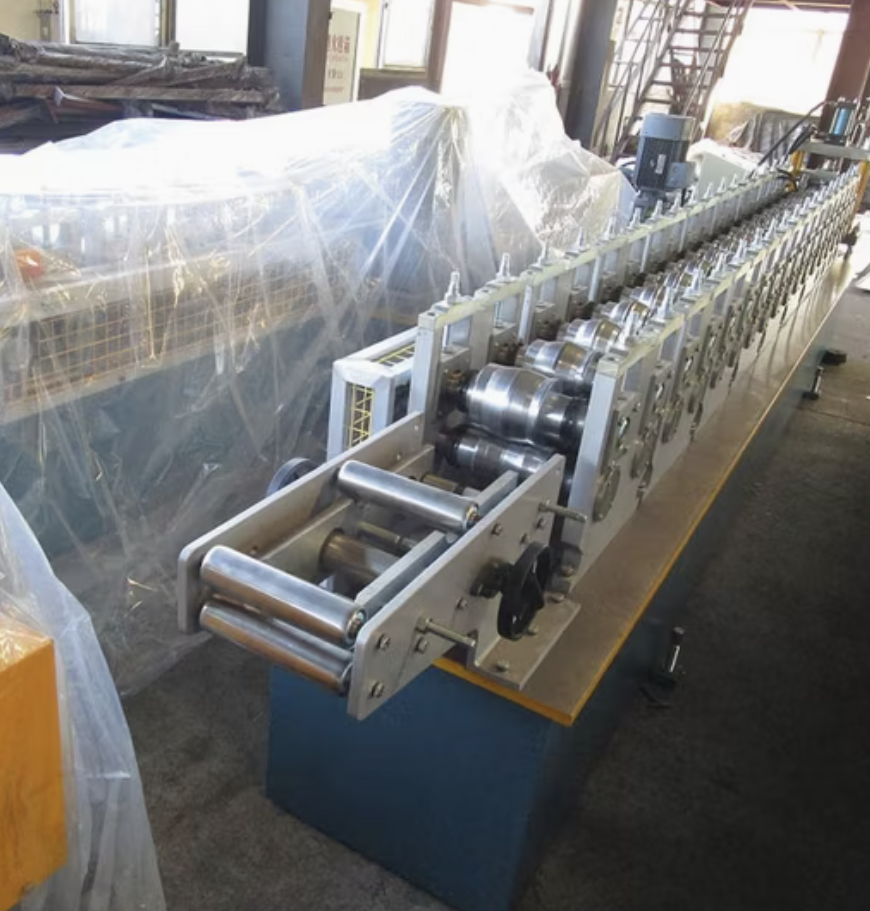

A Roller Shutter Roll Forming Machine is a specialized piece of equipment used to produce high-quality roller shutter slats for doors, windows, and industrial enclosures. These machines are widely used in construction, security, and industrial sectors due to their efficiency, precision, and ability to handle a variety of materials and profiles. The machine's modular design ensures adaptability to different profile designs and material thicknesses.

The roller shutter roll forming machine typically includes:

Below are the general specifications for a standard Roller Shutter Roll Forming Machine:

Q1: What materials can be processed using a Roller Shutter Roll Forming Machine?

A1: The machine can process galvanized steel, stainless steel, aluminum, and coated steel with thicknesses ranging from 0.3 mm to 1.5 mm.

Q2: What is the typical production speed of the machine?

A2: The standard production speed is 10–25 meters per minute, but higher speeds are achievable with advanced servo systems.

Q3: Can the machine handle different roller shutter profiles?

A3: Yes, the machine is designed with modular tooling, allowing it to produce various roller shutter profiles. Custom dies can be provided for unique designs.

Q4: What is the lifespan of the rollers and blades?

A4: Rollers and blades are made from heat-treated high-grade steel, ensuring a lifespan of 5–10 years with proper maintenance.

Q5: Is the machine compatible with international power standards?

A5: Yes, the machine can be customized to work with different power supplies, such as 220V, 380V, or 440V, and frequency settings of 50 Hz or 60 Hz.

Q6: What optional features are available?

A6: Optional features include an automatic stacking system, remote PLC operation, uncoilers, recoilers, and enhanced safety enclosures.

Q7: How long does it take to set up the machine?

A7: Installation and setup typically take 2–3 days, depending on the factory layout and operator expertise.

Q8: What kind of maintenance is required?

A8: Routine maintenance includes lubrication of moving parts, periodic inspection of rollers and cutting blades, and checking the PLC system for updates or errors.

Q9: Does the machine come with a warranty?

A9: Most manufacturers offer a 12–24 months warranty covering parts and service (excluding wear parts like blades).

Q10: What industries commonly use roller shutter profiles?

A10: Industries such as construction, automotive, security, and industrial storage widely use roller shutter profiles for doors, windows, and enclosures.

Copyright 2026 © Machine Matcher.