To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

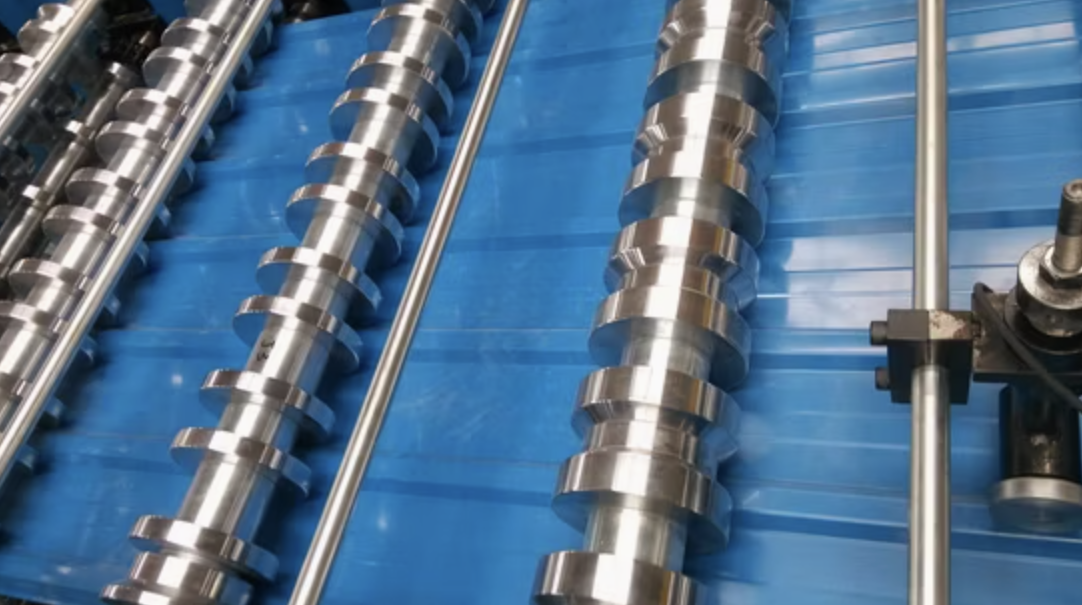

A Roof Panel Roll Forming Machine is designed to produce high-quality, durable metal roof panels used in various construction projects, such as residential, commercial, and industrial roofing. These machines are efficient, versatile, and engineered to handle different types of metal materials, including galvanized steel, aluminum, and copper. They shape metal coils into uniform, high-precision roof panels that provide excellent protection from environmental factors and enhance the aesthetic appeal of buildings.

The machine operates by feeding a coil of metal through a series of rollers, which progressively shape it into the desired profile. Once the metal reaches the final stage of the machine, it is cut to the required length with a hydraulic or servo cutting system. These machines offer features like high-speed production, automated controls, and the ability to create different profiles, making them essential for companies specializing in roofing solutions.

A Roof Panel Roll Forming Machine can work with various metals, including galvanized steel, aluminum, copper, and sometimes stainless steel, depending on the model and roller material.

Production speed varies but generally ranges between 10 to 20 meters per minute. Some advanced models may have higher speeds, but this depends on factors like material thickness and machine configuration.

Most Roof Panel Roll Forming Machines use a hydraulic or servo-driven cutting system. This allows for precise cuts without deforming the profile, ensuring a clean and accurate finish.

Regular maintenance includes lubricating moving parts, checking the electrical system, cleaning rollers and cutters, and inspecting safety features. This keeps the machine running smoothly and extends its lifespan.

Yes, many Roof Panel Roll Forming Machines are designed to be versatile. By adjusting the rollers or changing the forming dies, you can create different roof panel profiles, such as standing seam, corrugated, or trapezoidal profiles.

Installation and setup depend on the machine’s complexity and size. Typically, it takes between 1 to 3 days with an experienced technician. Additional time may be needed for testing and calibration.

Yes, extras like automatic stackers, uncoilers, and coil handling systems can significantly enhance productivity by reducing manual handling and streamlining the production process.

Roof Panel Roll Forming Machines come with safety guards around moving parts, emergency stop buttons, and sometimes an interlock system to protect operators during operation.

Consider factors like material type, desired profile, production speed, panel dimensions, and whether additional features like stackers or remote controls are needed. Your budget and production volume will also influence your decision.

Regular maintenance, quality control checks, and ensuring proper operator training are key. Using high-quality materials compatible with the machine also contributes to its longevity and performance.

A Roof Panel Roll Forming Machine is an efficient and reliable choice for businesses producing roofing solutions, offering a blend of speed, precision, and flexibility. With a range of optional features and straightforward maintenance, it’s an invaluable tool for consistent, high-quality roof panel production.

Copyright 2026 © Machine Matcher.