To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Roof trim roll forming machines are essential in manufacturing precise and high-quality roof trim profiles used in construction projects. These machines streamline the production process, ensuring consistency, efficiency, and durability of the profiles. The roof trims created by these machines serve critical roles, including weatherproofing, edge finishing, and aesthetic enhancement of roofs. In Canada, the demand for roof trim roll forming machines has risen due to increased construction activities and the focus on energy-efficient and durable building materials.

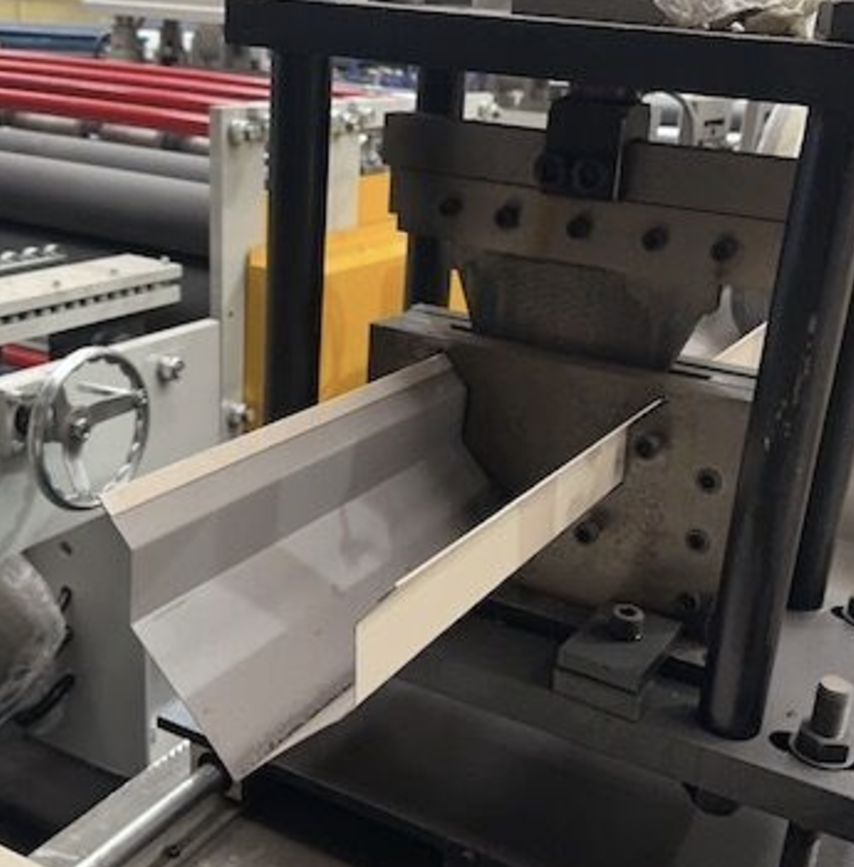

A roof trim roll forming machine is designed to produce various profiles of roof trims, such as drip edges, rake trim, or base flashing, from metal coils. It operates with advanced systems, offering precise cuts, smooth finishes, and high-speed production. The machine integrates automation to reduce labor costs and improve overall productivity.

Below are typical specifications of a high-quality roof trim roll forming machine tailored for the Canadian market:

This machine can produce various profiles such as drip edge, rake trim, J-channel, and base flashing. Custom profiles are also possible based on requirements.

The machine works with galvanized steel, pre-painted steel, aluminum, and stainless steel, commonly used in Canadian roofing projects.

Yes, the machine can be customized to produce profiles with specific dimensions according to your project requirements.

A typical roof trim roll forming machine requires a space of approximately 15 m x 3 m, depending on the machine model and additional components.

Delivery times vary but generally range between 8 to 12 weeks, including manufacturing and shipping.

Manufacturers typically provide installation assistance, operator training, and 12-month warranties. Remote troubleshooting and local technician services may also be available.

Many suppliers offer financing options or lease plans tailored to Canadian businesses. It’s best to check with the vendor directly.

Roof trim roll forming machines are indispensable for the Canadian construction industry. With their precision, efficiency, and adaptability, they cater to the growing demand for high-quality roofing solutions. If you’re considering investing in a roof trim roll forming machine in Canada, this guide should help you make an informed decision. For further assistance, contact a trusted supplier for detailed specifications and recommendations based on your needs.

Copyright 2026 © Machine Matcher.