To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

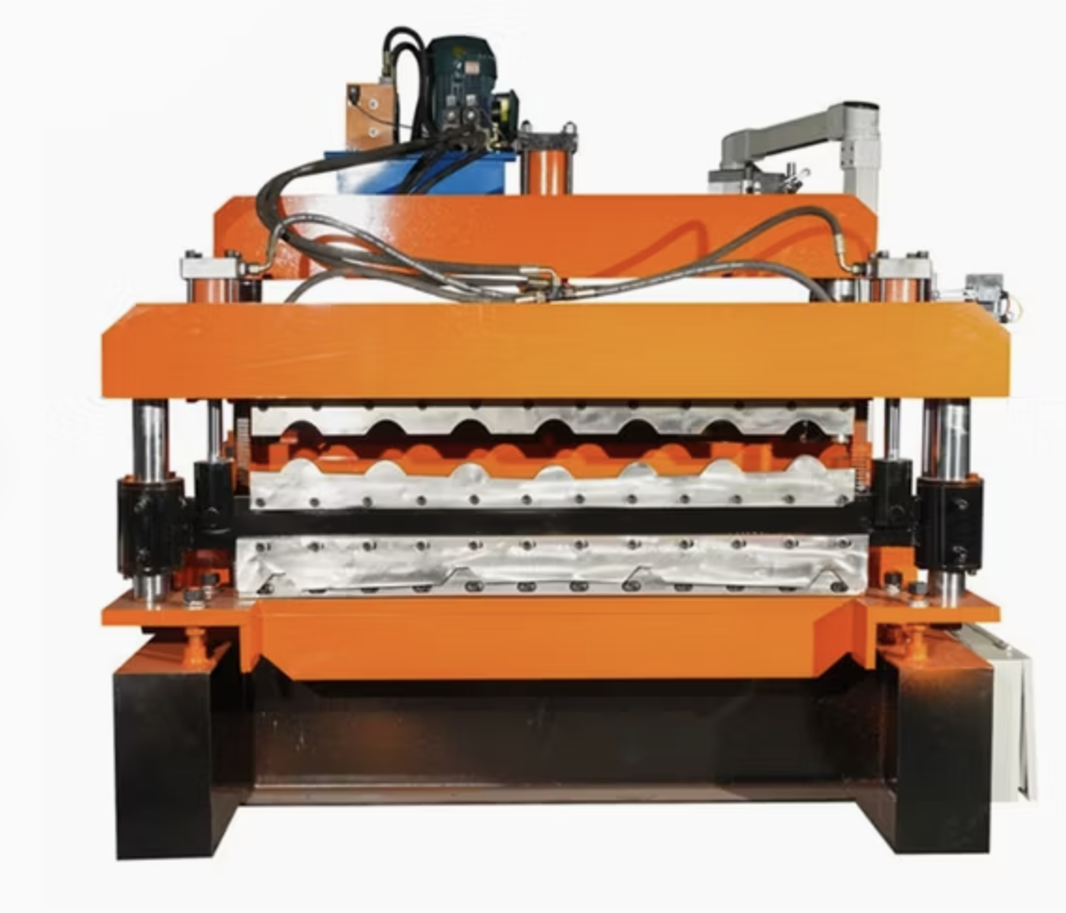

A roofing sheet roll forming machine is a specialized piece of equipment used to manufacture metal roofing sheets in various profiles. These machines are widely used in the construction industry for producing roofing materials that are durable, weather-resistant, and cost-effective. In Argentina, the demand for these machines is growing due to the increasing construction of residential, commercial, and industrial buildings.

Roofing sheet roll forming machines are designed to produce consistent, high-quality metal roofing sheets with precision. The machines transform flat metal coils into curved or straight roofing panels in a continuous process, ensuring uniformity and efficiency.

Key Features:

Materials Processed:

Q1: What types of roofing profiles can be made with these machines?

A1: Roofing sheet roll forming machines can produce corrugated, trapezoidal, and standing seam profiles. Custom designs are also available based on your requirements.

Q2: What is the power requirement for operating these machines in Argentina?

A2: Most machines operate on a standard power supply of 380V/50Hz, which is common in industrial setups in Argentina. Customized power configurations are also available.

Q3: How long does it take to set up and install a roofing sheet roll forming machine?

A3: Installation typically takes 1-2 days, depending on the machine’s complexity and the site’s readiness.

Q4: Is training provided for operating the machine?

A4: Yes, most suppliers offer training sessions for operators to ensure smooth operation and maintenance.

Q5: Can these machines handle recycled steel?

A5: Yes, as long as the recycled steel meets the required specifications (thickness, width, and material quality).

Q6: What maintenance is required for these machines?

A6: Regular maintenance includes cleaning rollers, checking hydraulic systems, lubricating moving parts, and inspecting the control system for errors.

Q7: Are spare parts readily available in Argentina?

A7: Many suppliers provide spare parts locally or ensure quick delivery from international distributors.

Q8: What is the cost range for these machines?

A8: The cost varies based on specifications and optional features. Basic models may start at $20,000, while advanced models with customizations can go up to $100,000 or more.

Copyright 2026 © Machine Matcher.