To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

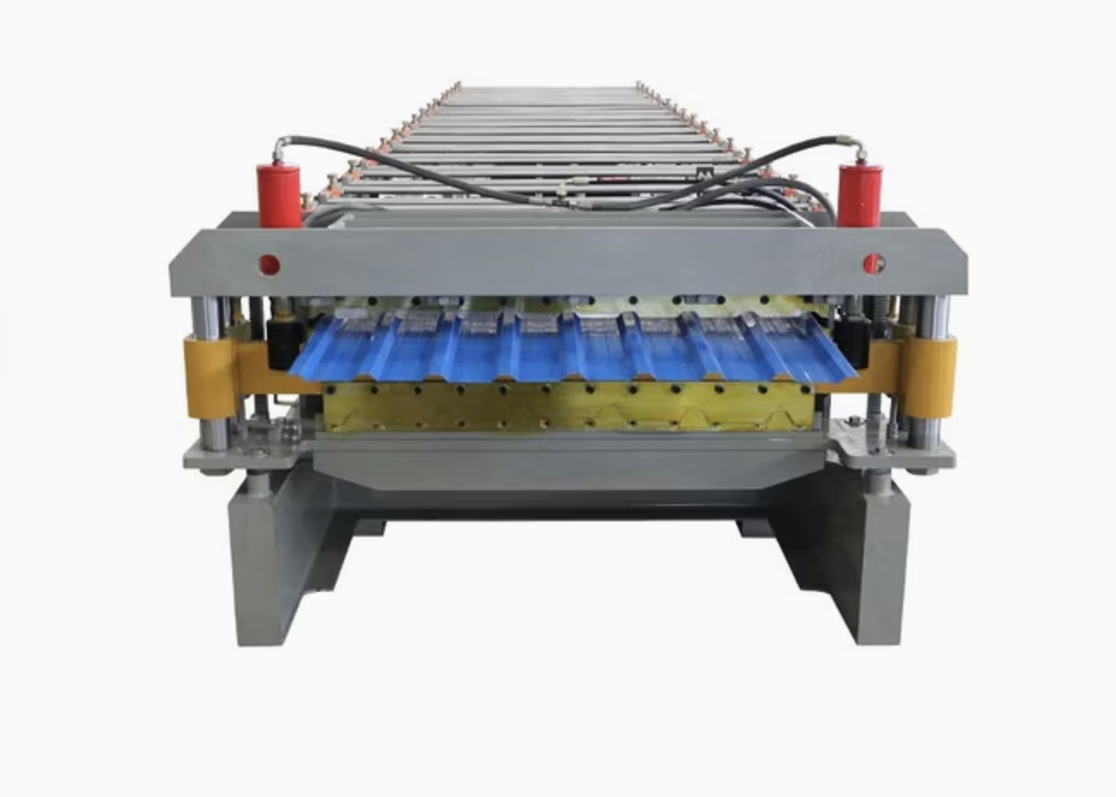

A roofing sheet roll forming machine is a specialized piece of equipment used to produce metal roofing sheets of various profiles and dimensions. These machines are essential in Brazil's construction and infrastructure sectors, where roofing sheets are used for residential, commercial, and industrial projects. The versatility, efficiency, and cost-effectiveness of roll forming machines make them indispensable for manufacturers and builders.

A roofing sheet roll forming machine is designed to transform coiled metal sheets into precise roofing profiles. The machine utilizes a series of rollers, which gradually shape the metal into the desired profile as it passes through. This automated process ensures consistency, high production rates, and minimal material waste.

The roofing sheets produced by these machines are commonly used for:

The machine can be customized to produce various profiles such as corrugated, trapezoidal, and standing seam panels, catering to Brazil's diverse construction needs.

Here are the typical specifications for a roofing sheet roll forming machine:

Q1. What types of materials can be used in a roofing sheet roll forming machine?

A1: Common materials include galvanized steel, pre-painted steel, aluminum, and zinc-coated sheets. These materials are selected based on the intended application and environmental factors.

Q2. Can the machine produce multiple profiles?

A2: Yes, most machines are designed to accommodate interchangeable rollers, allowing manufacturers to produce various profiles like trapezoidal, corrugated, and standing seam panels.

Q3. What is the average production speed of the machine?

A3: The production speed typically ranges from 10 to 25 meters per minute, depending on the material and profile requirements.

Q4. Is the machine compatible with Brazil’s power supply?

A4: Yes, the machine can be customized to work with Brazil's standard voltage and frequency (220V or 380V, 50/60Hz).

Q5. What maintenance is required for optimal performance?

A5: Regular maintenance includes lubricating rollers, checking the PLC system, tightening bolts, and ensuring the cutting blades remain sharp.

Q6. How is the machine installed?

A6: Installation involves assembling the machine components, connecting the electrical system, and calibrating the rollers for the specific profile. Professional technicians are often recommended for the setup.

Copyright 2026 © Machine Matcher.