To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

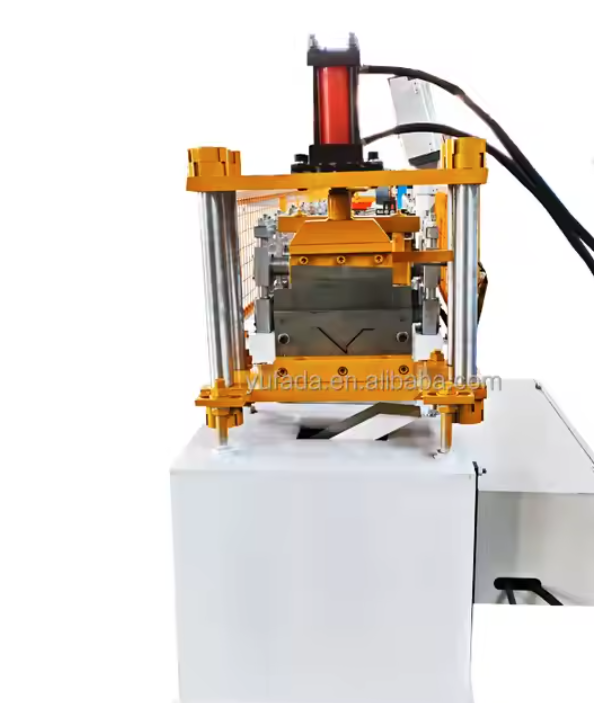

Sheet Metal Flashing Roll Forming Machine – United Arab Emirates Edition

High-Precision Custom-Built Flashing Fabrication for UAE Construction & Roofing Industries

The Sheet Metal Flashing Roll Forming Machine is a precision-engineered system designed for the efficient production of custom metal flashing profiles used in roofing, cladding, window trim, parapet walls, and building edge detailing. Designed to serve the unique demands of the UAE construction and roofing industry, this machine delivers high accuracy, speed, and durability in continuous forming operations.

Built for commercial-scale output and tailored to the Gulf region’s requirements, the machine can handle a wide range of materials including pre-painted steel, galvanized steel, and aluminum. It’s ideal for contractors, construction material suppliers, and manufacturing plants producing drip edge, apron flashing, sidewall and endwall flashing, window trim, or custom architectural metal components.

This roll forming machine is custom-built, made to your required profile shape, and shipped directly to any location in the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and beyond.

Commercial and residential roofing

Cladding and façade systems

HVAC and waterproofing

Architectural metalwork

Steel frame construction

Modular and prefabricated buildings

Machine Type: Sheet Metal Flashing Roll Forming Machine

Production Speed: 12–30 meters/min (adjustable based on material and complexity)

Material Thickness Range: 0.3 – 0.8 mm

Material Width Range: 150 – 600 mm

Material Types: Galvanized steel, pre-painted steel, aluminum, stainless steel

Material Yield Strength: Up to 300 MPa

Roller Material: GCr15 steel, hardened and precision ground

Roller Surface Treatment: Hard chrome plating for wear resistance and corrosion protection

Number of Forming Stations: 10–16 stations (depending on profile)

Roller Shaft Diameter: 50 mm

Shaft Material: High-tensile steel (quenched & tempered)

Main Drive Type: Chain or gear drive system

Power: 380V / 50Hz / 3-phase (UAE compatible)

Motor Power: 5.5 – 7.5 kW

Cutting Method: Hydraulic post-cutting for clean, accurate edges

Blade Material: Cr12Mov high-grade tool steel, heat-treated

Control Type: PLC-based (Siemens, Delta, or Mitsubishi)

Operating Mode: Fully automatic with touchscreen HMI interface

De-coiling System: Manual or hydraulic decoiler (optional motorized decoiler)

Punching/Notching System: Optional pneumatic or hydraulic system, programmable

Machine Frame: Welded steel base, precision machined

Thickness of Frame Steel: 16 – 20 mm

Profile Shape: Custom – drip edge, rake trim, apron flashing, Z-trim, etc.

Profile Width and Depth: Based on customer drawing/specification

Length Tolerance: ±1 mm

Safety Features:

Full protective covers/guards over rotating components

Emergency stop button on main and remote panels

Overload protection and power cut-off system

Prices start from: USD $24,000 – $38,000 (based on configuration and profile complexity)

What affects the final price:

Profile complexity and material width

Optional features such as punching, servo feeders, or stackers

Automation level (manual vs. fully automatic)

Brand of PLC and motor systems

Frame type and decoiler system

Location: All machines are new, custom-built to your specifications, and delivered across the UAE from our trusted manufacturing partners. Delivery and installation support available in Abu Dhabi, Dubai, Sharjah, Ajman, Al Ain, and other Emirates.

Warranty: 1-year warranty from dispatch date. Long-term maintenance and technical support available.

Need a quote?

If you have profile drawings, dimensions, or material specs, send them to [email protected] for a tailored quotation.

Q1: What types of profiles can this machine make?

A: It can manufacture a wide variety of flashing profiles such as drip edge, apron, Z-bar, rake trim, valley flashing, window trim, and custom shapes based on your drawings.

Q2: Can this machine run pre-painted coils?

A: Yes. The rollers are chrome-treated and designed to run pre-painted and coated material without damaging the finish.

Q3: How long does delivery and installation take in the UAE?

A: Standard delivery is 8–12 weeks from order confirmation. On-site installation and training in the UAE are available upon request.

Q4: What is the power requirement for operation in the UAE?

A: Machines are built to operate on 380V / 50Hz / 3-phase, which is standard in the UAE.

Q5: Can I add punching or notching to the profile?

A: Yes. Optional hydraulic or pneumatic punching systems can be integrated for slots, holes, and custom notches.

Q6: Do you provide operator training?

A: Yes. We offer remote and on-site operator training and setup guidance to ensure smooth machine commissioning.

The Sheet Metal Flashing Roll Forming Machine is the ideal choice for UAE-based contractors, manufacturers, and building product suppliers looking to produce high-quality, accurate flashing profiles. With robust construction, automation-ready controls, and customization to your exact profile shape, this machine will streamline your flashing production while maintaining consistent precision.

Contact Machine Matcher

📩 Email: [email protected]

📦 Delivery: Across the United Arab Emirates

🛠 Support: 1-year warranty, full after-sales service, and spare parts availability

Let us match you with the right machine — custom-built and built to last.

Copyright 2026 © Machine Matcher.