To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

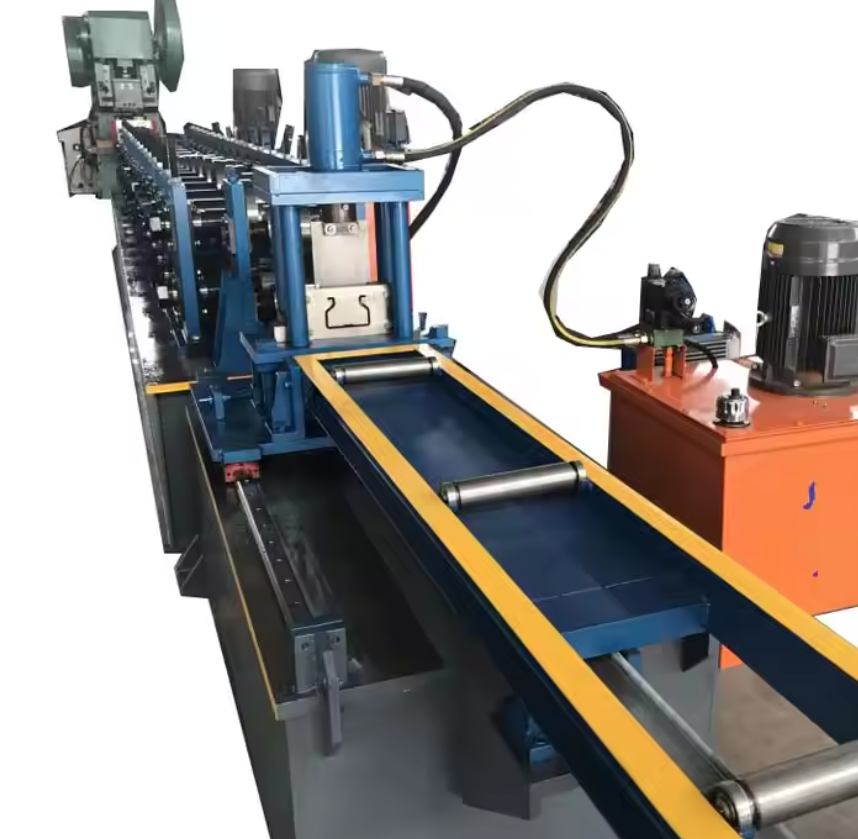

Sheet Metal Rack Storage Roll Forming Machine – UAE Market Focus

The Sheet Metal Rack Storage Roll Forming Machine is an industrial-grade solution designed for high-volume, high-precision manufacturing of metal storage rack profiles. Engineered for the needs of businesses in the United Arab Emirates (UAE), this machine is capable of producing structural shelving and racking components used in logistics centers, warehouses, and industrial storage facilities.

Built to handle a wide range of material types and thicknesses, this roll forming system offers automated, continuous production with exact profile control, minimizing waste and maximizing efficiency.

This machine caters to several sectors across the UAE, including:

Warehousing & Logistics – For producing storage shelving, pallet racks, and cantilever systems.

Retail Storage Solutions – Used to manufacture store display racking and gondola shelves.

Industrial Equipment Suppliers – For producing components of industrial shelving systems.

E-Commerce Fulfillment Centers – To build modular rack systems for inventory handling.

Automotive Parts Storage – For OEM and aftermarket parts storage systems.

Example Applications:

Rack uprights and beams

Shelving support profiles

Slotted angle racks

Load-bearing channels

| Specification | Detail |

|---|---|

| Machine Type | Roll Forming Machine for Storage Rack Profiles |

| Production Speed | 10–25 meters/min (depending on profile design) |

| Material Thickness Range | 1.2 – 2.5 mm |

| Material Width Range | 100 – 600 mm |

| Material Types | Cold-rolled steel, galvanized steel, high-strength steel |

| Material Yield Strength | Up to 350 MPa (50 ksi) |

| Roller Material | GCr15 (high-grade bearing steel) |

| Roller Surface Treatment | Hard chrome plated (for anti-corrosion and long wear life) |

| Number of Forming Stations | 16–24 stations (customizable) |

| Roller Shaft Diameter | 70 mm |

| Shaft Material | 45# high-strength steel, precision-ground |

| Main Drive Type | Gearbox or chain drive (based on preference) |

| Power (UAE Compatible) | 380V, 50Hz, 3-phase |

| Motor Power | 11 – 15 kW |

| Cutting Method | Hydraulic post-cut system |

| Blade Material | Cr12Mov (heat-treated) |

| Control Type | PLC with touch screen (Siemens, Delta, or Mitsubishi) |

| Operating Mode | Fully automatic |

| De-coiling System | Manual or hydraulic uncoiler (3–5 ton capacity) |

| Punching/Notching System | Hydraulic punching (customized for slotted holes, notches) |

| Machine Frame | Welded structural steel, stress-relieved |

| Thickness of Frame Steel | 18–20 mm |

| Profile Shape | Custom rack profile with slots or perforations |

| Profile Width and Depth | Varies based on customer requirement (commonly 40–80 mm wide, 40–60 mm deep) |

| Length Tolerance | ±1.0 mm |

| Safety Features | Emergency stop button, protective guards, overload protection system |

Common Materials: Cold-rolled steel, galvanized steel

Gauge Range: 14 – 20 gauge (1.2 – 2.5 mm)

Typical Strength: 30–50 ksi yield strength depending on profile design

Profile-specific tooling

Inline punching and slotting units

Automatic stackers

Coil car tippers and hydraulic decoilers

Remote monitoring PLC systems

Servo feeder integration

Safety light curtains and enclosure options

Prices start from: $65,000 USD

(Depending on features, automation level, and tooling complexity)

What Affects Final Price:

Profile design complexity

Number of forming stations

Level of automation (manual vs. fully automatic)

Inclusion of punching/notching systems

Type of de-coiler and stacker

Electrical configuration or special components for the UAE market

All machines are new and custom-built to your profile and production needs. Delivery available across the UAE, including:

Abu Dhabi

Dubai

Sharjah

Ajman

Al Ain

Ras Al Khaimah

Fujairah

Machines are manufactured by trusted international partners and shipped directly to your facility.

UAE Electrical Compliance (380V / 50Hz)

Tailored Profile Tooling for rack systems used in GCC markets

Fully Automated Controls reduce labor and error

Robust Frame Build for heavy-duty, long-term use

Inline Punching Capability to save time and post-processing

Short Lead Times with fast export processing

One-Year Warranty + Full spare parts and after-sales service

→ These advantages translate to:

Lower production costs

Higher throughput per shift

Consistent, high-quality rack components

Fewer manual interventions

If you have:

Profile drawings

Material specifications

Power requirements

Special length or hole requirements

Please send your details to:

[email protected]

Our team will provide a customized quote with machine specifications suited to your needs.

Q: Can this machine produce multiple rack profiles?

A: Yes. With interchangeable tooling or adjustable roll stations, the machine can produce several sizes or styles of rack profiles.

Q: How long does installation take in the UAE?

A: Typically 5–7 days, including operator training. Remote or on-site support is available.

Q: Can we customize the punching pattern?

A: Absolutely. Just provide a hole layout drawing and our engineers will integrate the right punching system.

Q: Does this machine require a skilled operator?

A: No. The PLC-based control system is user-friendly and training is provided with installation.

Q: What support do you provide post-sale?

A: One-year warranty, lifetime technical support, spare parts availability, and optional maintenance packages.

For dependable, high-performance rack profile production in the UAE, the Sheet Metal Rack Storage Roll Forming Machine from Machine Matcher is your go-to solution. Precision-engineered for durability, efficiency, and local compliance, it's the perfect investment to scale your production and meet growing storage demands.

Copyright 2026 © Machine Matcher.