To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

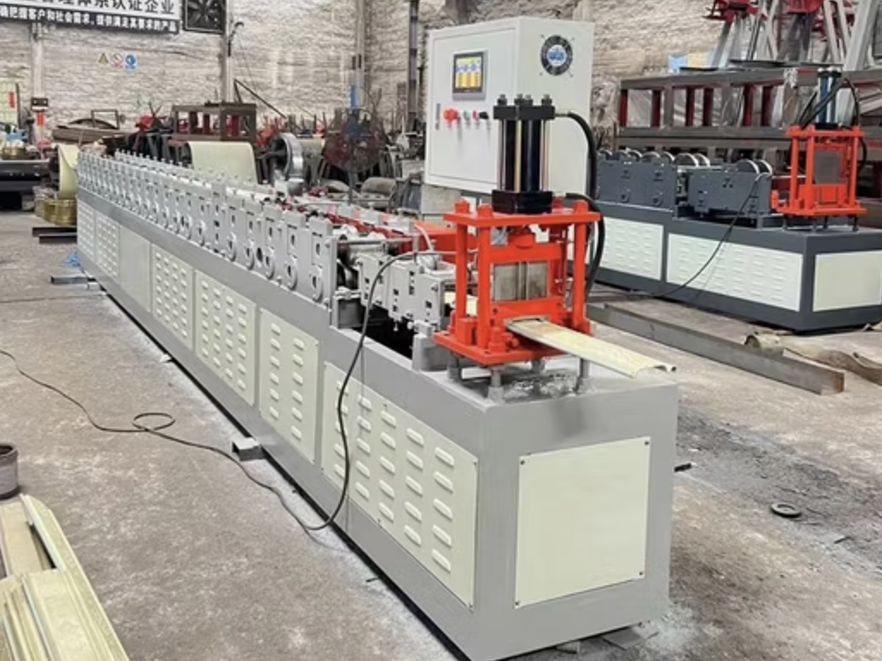

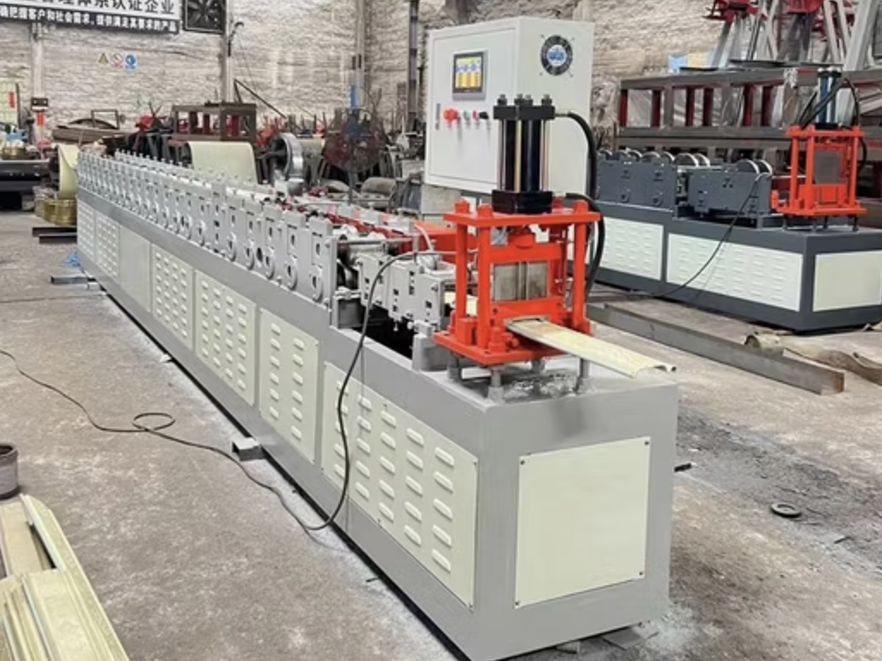

A shutter door roll forming machine is a specialized piece of equipment designed to produce high-quality shutter doors for industrial, commercial, and residential purposes. The machine's versatility, efficiency, and precision make it a preferred choice for manufacturers aiming to meet the increasing demand for durable and customizable shutter doors.

The shutter door roll forming machine is engineered to handle various profiles and materials, catering to Brazil's diverse industry needs. This equipment converts raw steel coils into finished shutter door slats through an automated and continuous roll forming process. The machine includes features for punching, notching, and cutting to exact lengths, ensuring precision and consistency.

| Category | Details |

|---|---|

| Roller Material | High-grade steel with hard chrome plating for durability and smooth operation |

| Material Thickness | 0.6 mm to 1.5 mm (customizable based on requirements) |

| Material Width | 100 mm to 300 mm (varies by profile) |

| Machine Frame | Welded steel frame for high stability |

| Forming Speed | 10–20 m/min (adjustable) |

| Cutting System | Hydraulic cutting system for precise, burr-free cuts |

| Punching Options | Pre-punching and post-punching available, controlled by a servo motor |

| Control System | PLC control system with a user-friendly interface |

| Motor Power | Main motor: 5–7.5 kW; Hydraulic station: 3–5 kW |

| Power Supply | 220V/380V/440V, 50/60 Hz (customizable for Brazil’s electrical standards) |

| Safety Features | Emergency stop buttons, safety enclosures, and overload protection |

| Extras | Decoiler (manual/automatic), stacker, and coil car for efficient material handling |

Q1: What materials can the shutter door roll forming machine process?

A1: The machine can process galvanized steel, stainless steel, and aluminum, which are commonly used in Brazil due to their resistance to corrosion and durability.

Q2: What is the standard power supply for machines in Brazil?

A2: Most machines in Brazil operate on 220V or 380V at 60 Hz. The machine can be customized to match these electrical standards.

Q3: How long does it take to set up the machine?

A3: The setup process typically takes 1–2 days, including alignment, calibration, and testing.

Q4: Can the machine produce custom shutter door profiles?

A4: Yes, the machine is highly customizable to produce profiles based on specific dimensions and designs requested by Brazilian manufacturers.

Q5: What is the average lifespan of the machine?

A5: With proper maintenance, the machine can last over 10 years.

Q6: Are spare parts and technical support available in Brazil?

A6: Yes, spare parts can be imported or sourced locally, and technical support is available either on-site or remotely.

Q7: What maintenance is required for the machine?

A7: Regular lubrication, cleaning of rollers, and inspection of the hydraulic and electrical systems are necessary to maintain optimal performance.

Q8: What is the production capacity of the machine?

A8: Depending on the material and profile, the machine can produce up to 1,000 shutter door slats per day.

Copyright 2026 © Machine Matcher.